LOWERING FEEDER

1.

Before

lowering

the

feeder,

make

sure

that

the

area under the feeder is clear of tools or foreign

objects.

2.

Release

safety

prop carefully.

If

feederhas

dropped

firmly down onto safety prop, it will be necessary to

raisethe feeder. After raising the feeder,

tum

engine

offand

release

safety

propas

instructed.

3.

Lower

feeder,

but

not

under

pressure.

Allow

feeder to come down with engine not running.

4. Fold side panels back with same in and out knuckle

motion used to raise

them.

5. Replace

the

hold

down

bolts on

each

side

panel,

and tighten.

!

CAUTION!

NEVERPAVEWITHHOLDDOWNBOLTSOOT. HINGE

FLAP

MAY

LIFT, LETTING ASPHALT

GET

INTO

FLIGHT CHAIN.

FEEDER FLIGHT CHAIN ADJUSTMENT

1. Raise feeders.

2.

Secure

safety

prop

to

prevent

feeders

from

accidentally lowering.

3. The feeder conveyor should run smooth when feeder

chain is properly

adjusted.

These

chains

should be

adjusted every 100 hrs.,to maintain smooth operations.

If irregular movement

of

the conveyor occurs, this is

generally a sign that an adjustment is needed. Follow

the procedures below in making

this

adjustment.

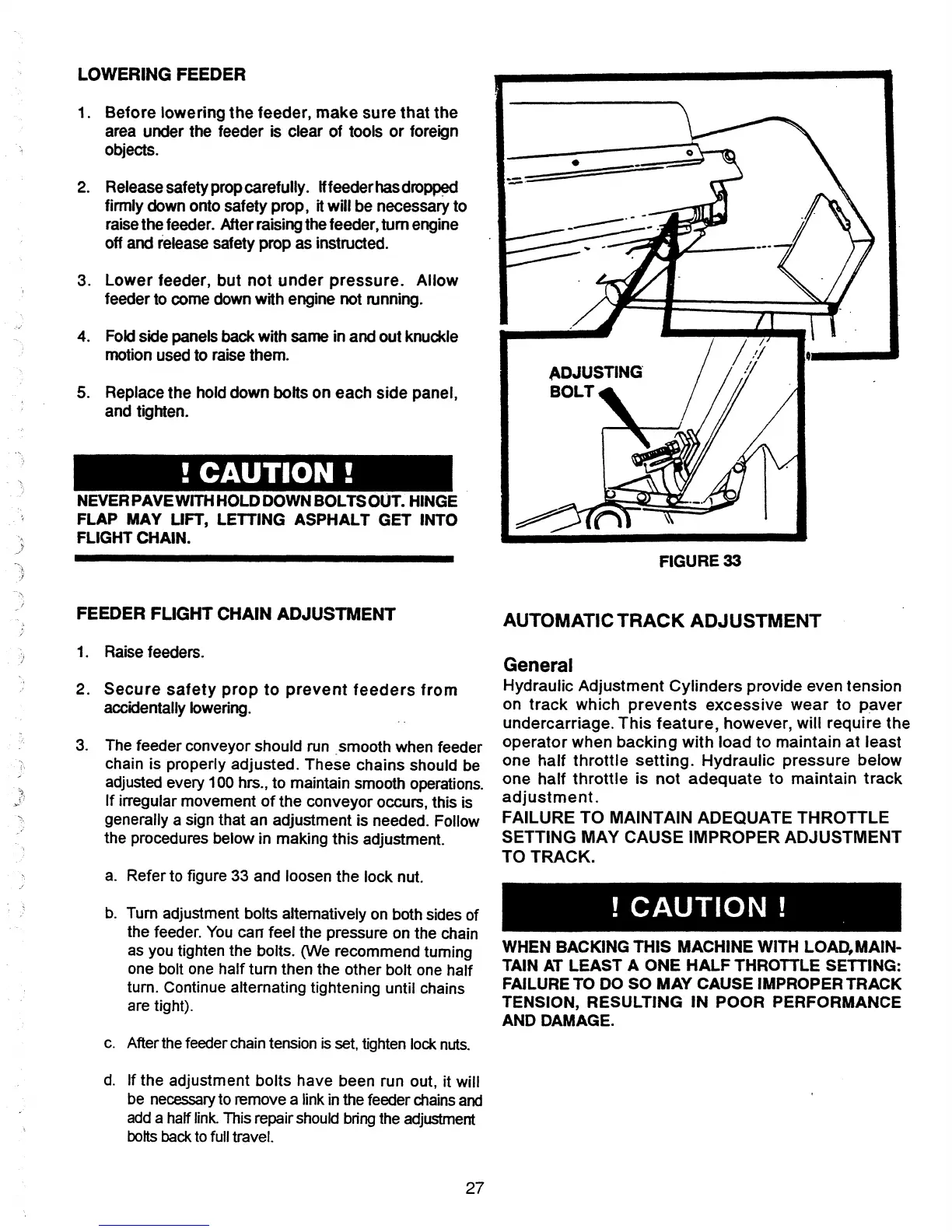

a. Refer to figure 33 and loosen

the

lock nut.

b. Turn adjustment bolts alternatively on both sides of

the feeder. You can feel the pressure on the chain

as you tighten the bolts.

(VVe

recommend turning

one bolt one

half

tum

then the other bolt one half

turn. Continue alternating tightening until chains

are tight).

c. After the feederchain tension is set, tighten lock nuts.

d. If the

adjustment

bolts

have

been run out, it will

be necessary to remove a link in the feeder chains

and

add a half

link.

This repair should bringthe adjustment

boltsbackto fulltravel.

27

FIGURE 33

AUTOMATIC

TRACK

ADJUSTMENT

General

Hydraulic

Adjustment

Cylinders

provide even tension

on

track

which

prevents

excessive

wear

to

paver

undercarriage.

This

feature,

however, will

require

the

operator

when

backing

with

load

to

maintain

at

least

one

half

throttle

setting.

Hydraulic

pressure

below

one

half

throttle

is

not

adequate

to

maintain

track

adjustment.

FAILURE TO MAINTAIN ADEQUATE THROTTLE

SETTING

MAY

CAUSE IMPROPER ADJUSTMENT

TO TRACK.

!

CAUTION!

WHEN

BACKING

THIS

MACHINE

WITH

LOAD,

MAIN-

TAIN AT

LEAST

A

ONE

HALF

THROTTLE

SETTING:

FAILURE TO DO SO

MAY

CAUSE

IMPROPER

TRACK

TENSION,

RESULTING

IN

POOR

PERFORMANCE

AND DAMAGE.

Loading...

Loading...