7. The pavercanoperate usingone side only. Material

from opposite side however, can not be augered to

the

working side.

This

is prevented

by

the

auger

center

cover. It is

possible

to leave

both

cut-offs

shut

and

open

the

end

gates

on

screed.

This

method

is generally

used

in doing

pot

holes

and

patching.

ROUTINE MAINTENANCE

GENERAL

Preventive maintenance on the Lee-Boy paver is a

simple

job

that

will

provide

years of

trouble-free

operation. Adjustments, also, are simple; they can be

performed, in the field, with ordinary hand tools. Engine

preventative maintenance, other than oil,

air

and fuel

filterchanges, is not

covered

in

this

section.

Refer

to

engine

operators

manual

for

engine

service

in-

formation. (NOTE: Foryourconvenience there is an oil

drain hose located in the tool box.)

10 - HOUR OR DAILY

ROUTINE MAINTENANCE

1. Cleaning the paver at

the

end of

the

working

day

whilethe machine is still hot is like putting money in

the bank. A paverthat is continuously left with mix

stuffed

in every

corner

is

going

to

increase

maintenance

costs.

Scrape

off

mix

and

spray

fuel

oil

on

the

screed

plate,

hopper,

etc.,

any

place

that

has

come in

contact

with

the

mix. Spray

down

the feeders

while

they are running. All

cleaning

should

be

performed

while

the

machine

is hot. (NOTE: For cold weather,

keep

conveyor

flight chain properly

oiled with fuel oil. This will

prevent conveyor from sticking inside of conveyor

pan. Neglect could result in conveyorbars bowing

if conveyor does stick.)

!

CAUTION

!

IF

MIX

IS ALLOWED TO REMAIN IN

THE

MACHINE

OVERNIGHT, POSSIBLE DAMAGE

CAN

RESULT

ON

START-UP

THE

NEXT

DAY.

POOR

"HOUSE-

KEEPING"WILL

INCREASEMAINTENANCECOSTS.

2.

Raise

feeders

(See

Adjustments

-

To

Raise

Feeders) and clean mix off all flat surfaces. This

operation is quick and simple when

the paveris still

hot.

Immediately

after

raising

feeders

place

the

safety

prop In position.

22

3. Fill fuel

tank

for

engine

and

spray

down

systemto

keep condensation from forming.

4.

Perform

engine

preventative

maintenance

as

described in your engine operators manual.

Any

engine preventative maintenance should always

beginwith an

oil check. Also, check oil level inoil bath

air cleaner.

(If EqUipped.)

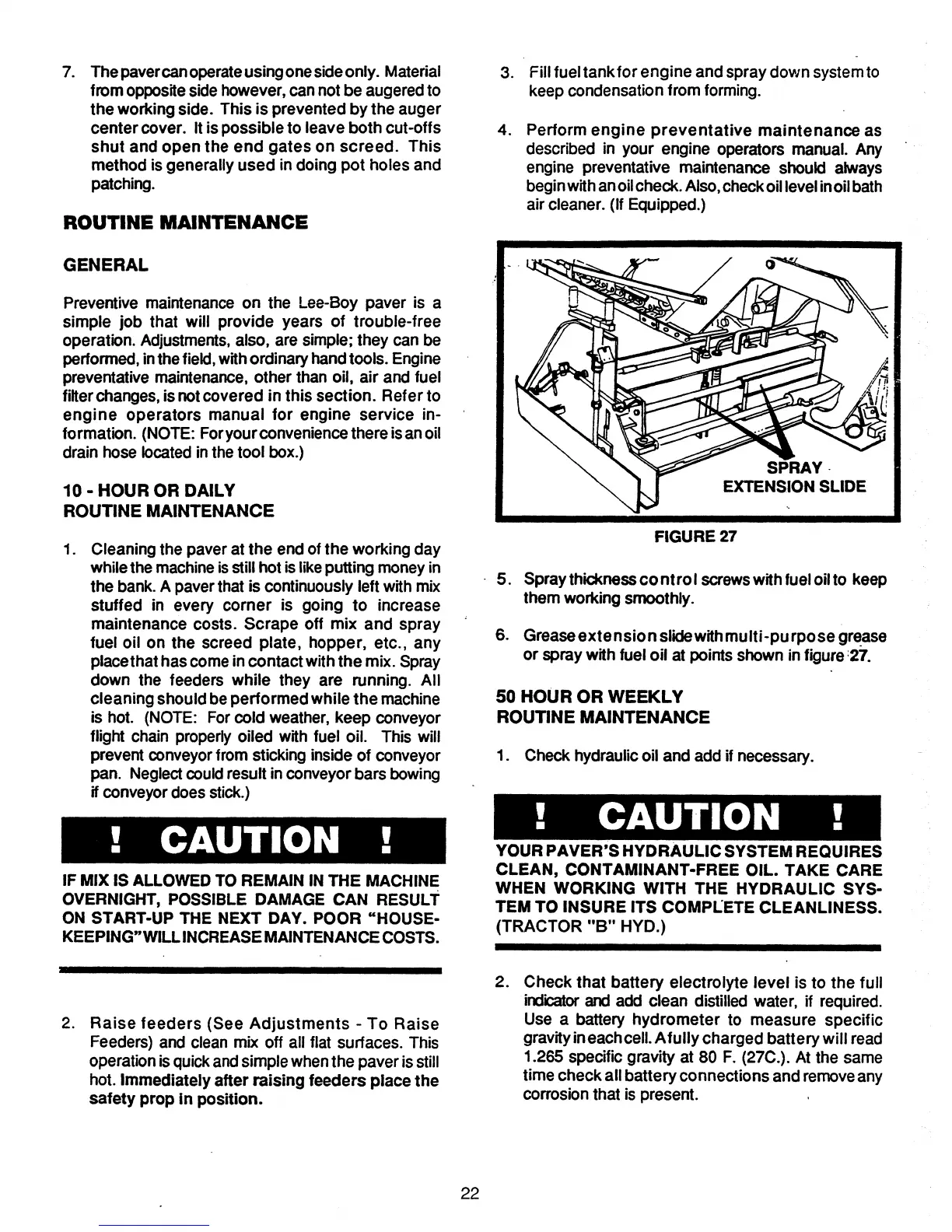

FIGURE

27

. 5. Spraythickness

co

ntroI screws withfuel oil to keep

them

working smoothly.

6. Grease

extension

slidewithmulti-purpose

grease

or spray with fuel

oil

at points shown in figure

:27.

50 HOUR OR

WEEKLY

ROUTINE MAINTENANCE

1. Check hydraulicoil and add if necessary.

!

CAUTION

!

YOUR

PAVER'S

HYDRAULIC

SYSTEM REQUIRES

CLEAN,

CONTAMINANT-FREE

OIL.

TAKE

CARE

WHEN

WORKING

WITH

THE

HYDRAULIC

SyS-

TEM

TO

INSURE

ITS

COMPLETE

CLEANLINESS.

(TRACTOR

"B"

HYD.)

2.

Check

that

battery

electrolyte

level

is to

the

full

irx:Jicator

and add clean distilled water, if required.

Use a

battery

hydrometer

to

measure

specific

gravityineach cell.

Afully

charged

battery

will

read

1.265 specific gravity at 80 F. (27C.). At the same

time

check

all

battery

connections

and remove any

corrosion that is present.

Loading...

Loading...