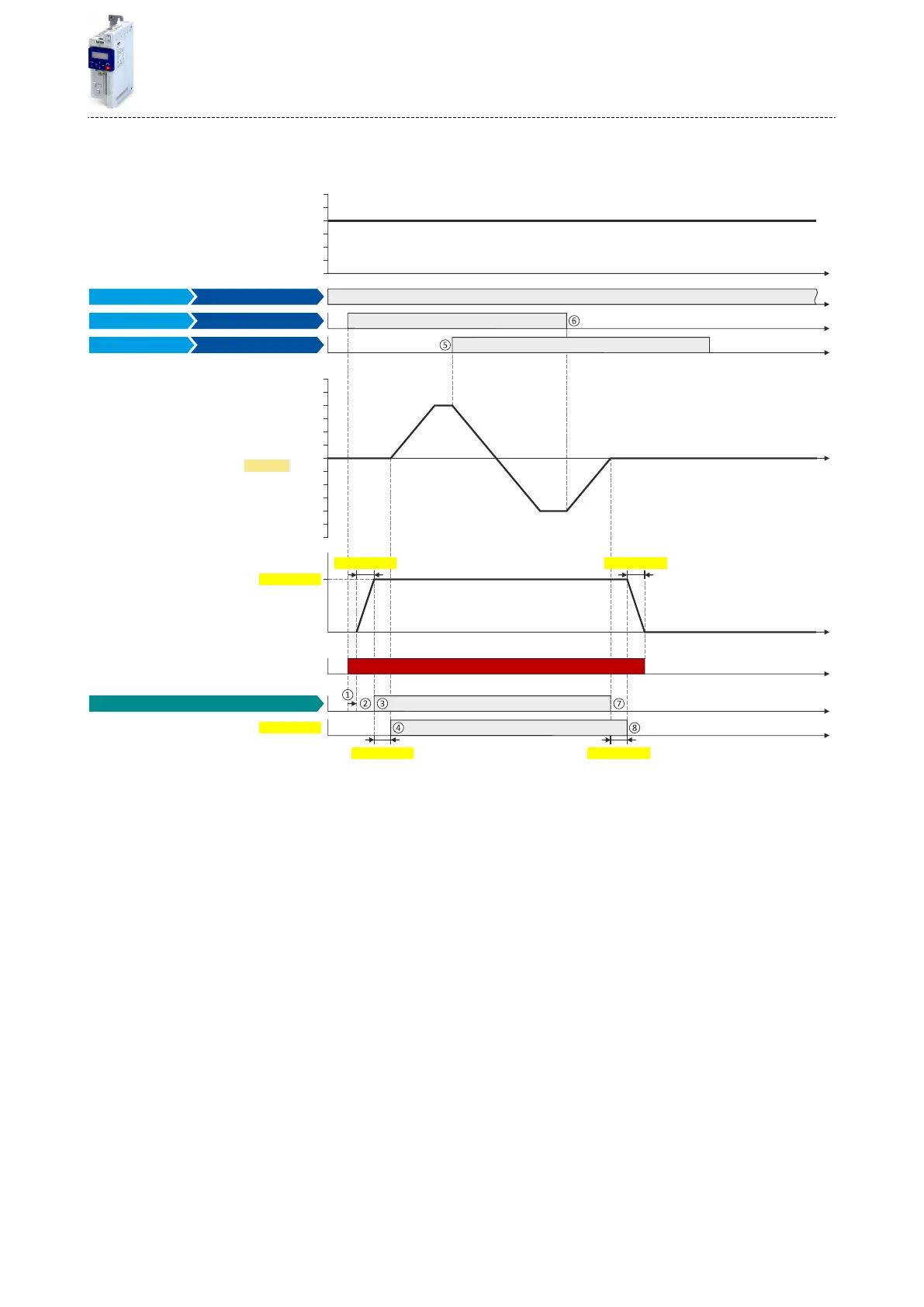

General mode of operaon

The following diagram demonstrates the general funconing in automac operaon:

t

t

t

t

0 Hz

30 Hz

10 Hz

20 Hz

40 Hz

50 Hz

60 Hz

-40 Hz

-60 Hz

-50 Hz

-30 Hz

-20 Hz

-10 Hz

t

0 Hz

30 Hz

10 Hz

20 Hz

40 Hz

50 Hz

60 Hz

t

t

t

t

0x2820:015

0x2820:002

0x2820:003

0x2820:013 0x2820:013

0x2DDD

0x2820:008

Holding load

Power section switched-on

Digital input 3 [13] Reversal rotation direction

Output frequency

Active [0]Brake released [1]

Brake status

Release holding brake [115]

Output signals

Output trigger

Digital input 1 [11] Run

Constant TRUE [1] Enable inverter

Input signals

Frequency setpoint selection

FunctionTrigger

①

If the inverter is enabled and no error is acve, the motor can be started with the "Run" funcon in forward rotang direcon.

The power secon is switched on and the motor is magnesed rst.

②

The brake holding load set in 0x2820:008 (P712.08) is build up via the ramp set in 0x2820:013 (P712.13).

③

The holding brake is released. For this purpose, the output trigger "Release holding brake [115]" is set to TRUE. This trigger must be

assigned to a digital output or, in the simplest case, to the relay which then switches the brake supply.

④

Aer the release me 0x2820:003 (P712.03) has elapsed, the motor is accelerated to the setpoint.

The brake status "Brake released [1]" is displayed in 0x2820:015 (P712.15).

⑤

In case the direcon of rotaon reverses, the holding brake remains released.

⑥

If "Run" is set to FALSE, the motor is stopped with the stop method set in 0x2838:003 (P203.03). In the example: Stop with standard ramp.

⑦

Then the holding brake is closed again.

⑧

Aer the closing me 0x2820:002 (P712.02) has elapsed, the brake status "Acve [0]" is displayed in 0x2820:015 (P712.15).

The brake holding load is reduced again via the ramp.

Addional funcons

Holding brake control

Brake holding load

305

Loading...

Loading...