13

www.lofrans.com

Problem Possible causes Solution

7. The shaft does

not run well, is not

aligned, and so is

the gypsy and/or

the bell.

7.1 The shaft bent because the winch

was subjected to an excessive

load.

7.1 Check out that the procedures of use fall within the

specications of the winch.

(SERVICE) Uninstall the winch and replace the shaft. Take this

opportunity to replace worn parts, gaskets, seeger, tabs and oil.

8. Loss of oil between

the engine and the

gearbox body

8.1 The coupling of the engine is

loose and causes the worm screw

into an irregular rotation, leading

to loss of oil from the gasket.

8.2 (SERVICE) Find the reasons why the screws or nuts have

become loose. Uninstall the engine and check out the status

of the spindle and the hole of the worm screw. If an oval

form of the cylindrical part of the screw is observed (outer

hole and diameter) uninstall the winch and repair the dam-

aged parts on the bench. Check out if the oil has entered

into the electrical engine. Take this opportunity to replace all

gaskets, tabs, seeger, screws, oil, and any worn parts.

9. On installation, it is

found that the shaft

and the studs are

short for a correct

coupling with the

gearbox.

9.1 The request referred to the deck

thickness was wrong.

9.1 If the key shaft works in the gearbox along all its length, the

xing studs can be adapted. Otherwise, a longer shaft must

be requested.

10. The nger is

broken

10.1 Poor layout of the cable top or

rolling of the chain has broken

the nger. Check out the suita-

bility of the gypsy to work with

the nger.

10.1 Replace the nger.

10.2 In the event that the gypsy cannot work properly with the

nger, position the replacement kit (cap).

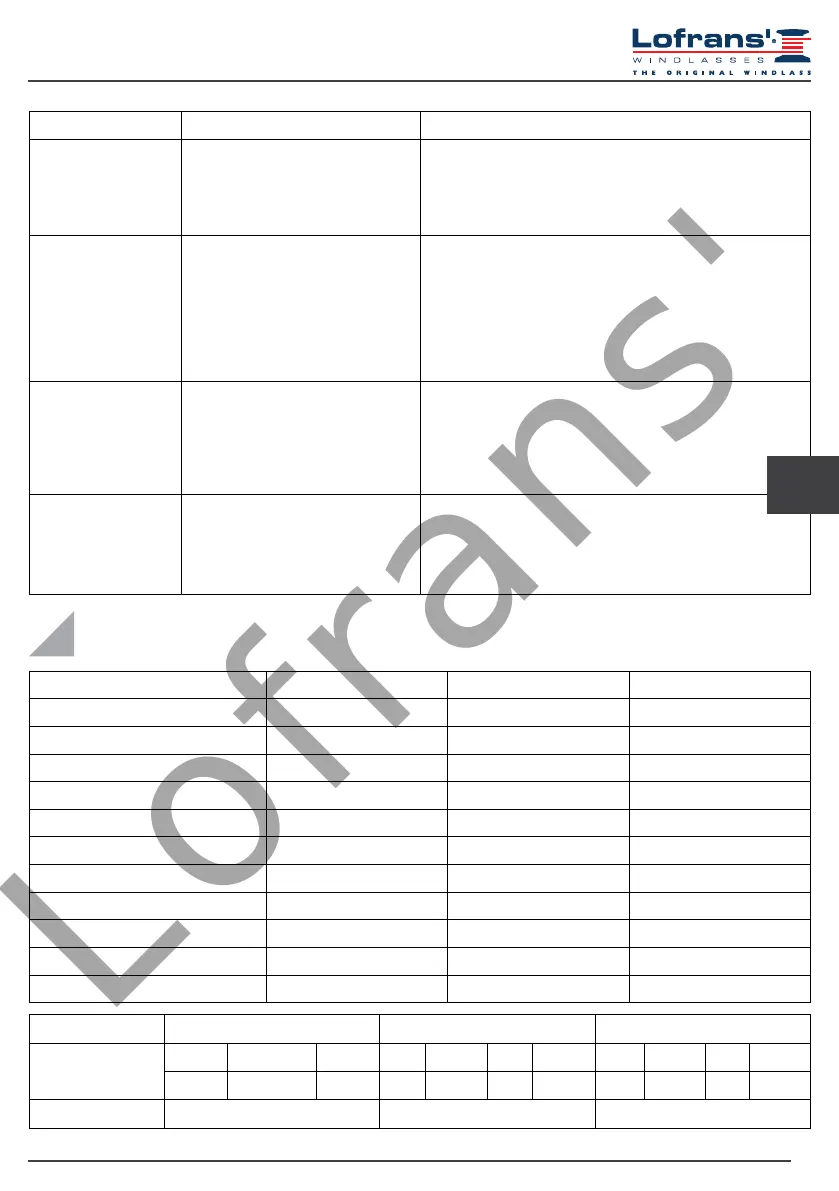

8 TECHNICAL DATA

Motor Power 500W 800W 1000w

Vessel Lenght Heavy Duty (ft) 20 - 30 25-35 30-40

Vessel Lenght Light Duty (ft) 30 - 35 35-40 35-45

Power Supply 12V 12V 12V

Maximum linear Load/Pull (Kg /lb) 630 / 1386 700 / 1540 900 / 1980

Maximum lift Load/Pull (Kg /lb) 345 / 759 380 / 836 425 / 935

Max Lift Working Load (Kg /lb) 95 / 209 100 / 220 125 / 275

Amps Work Load (A) 60 110 120

Max Line Speed (mt./min. / ft/min.) 26 / 78 28 / 84 30 / 90

Line Speed (mt./min. / ft/min.) 23 / 69 25 / 75 20 / 60

Net weight with Drum (Kg /lb) 12 / 27 14 / 31 17 / 38

Net weight Low Prole (Kg /lb) 11 /25 13 / 29 16 / 36

Gipsy 6mm 7mm 8mm

Chain supported

6mm 6mm 3/16” 7mm 7mm 1/4” 1/4” 8mm 8mm 5/16” 5/16”

ISO DIN 766 BBB ISO DIN 766 G4 BBB ISO DIN 766 G4 BBB

Rope supported 12mm - 1/2” 12mm - 1/2” 12mm - 1/2”

UK

Loading...

Loading...