6

X1 - X1 ALU

Insert always an articulated joint between the chain and the anchor so that the chain itself does not turn into as spiral.

3.9 Chain insertion

In order to guarantee performances and reliability, it is recommended to use a calibrated chain of the measure corresponding to the

gipsy supplied.

4.1 Electrical cable section

In order to obtain the maximum performances from the anchor windlass and safeguard the electrical system, it is essential that the

anchor windlass be wired with cables of sufcient section as suggested in the table.

4.2 Solenoid valves (Control Box)

Place it in a dry place near the capstan.

4.3 Circuit breakers

The circuit breakers recommended by Lofrans’ have an intervention curve and not a simple plate value. The switches selected for each

model guarantee the correct operation of the system.

4.4 Remote control electric panel board

The remote control electric panel board must be mounted in a comfortable position (such as the deck, the rudder or the cockpit), so that

the operator can see the capstan during the manoeuvre. Mount and seal the electric panel board so that the terminals remain in a dry

place.

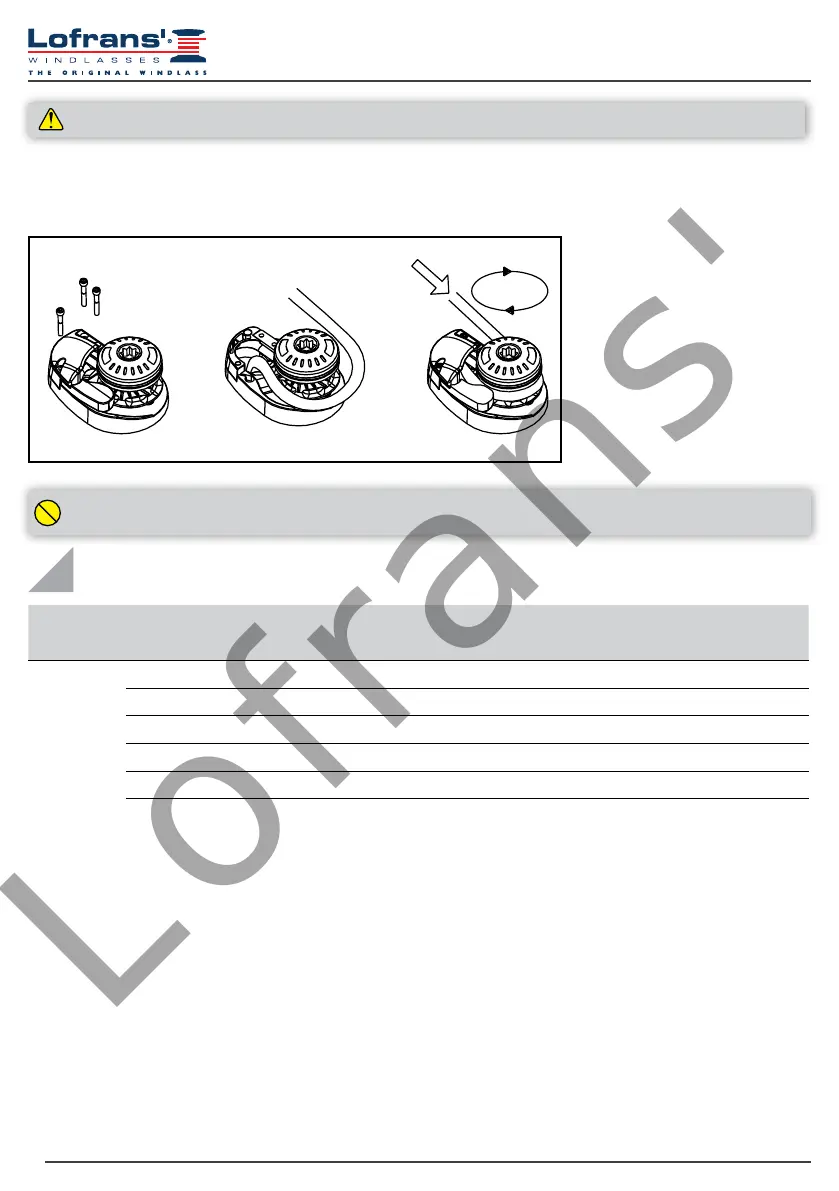

1. Remove the covering hood by

unscrewing the two seal screws.

2. Insert the chain into the hole and x

to a safe point.

3. Replace the hood by screwing the

xing screws.

4. Wrap the chain in the gipsy.

5. Recover all the chain by using the

motor, taking care that the chain

enters into the gipsy well aligned.

4 ELECTRICAL SYSTEM

Model

Motor Power

(W)

Voltage (V)

Contactor

(A)

Cable sizing according length of cable (positive + negative)

0-15 m 0-50 ft 15-25 m 50-75 ft

X1/X1 Alu

500 12 16 mm

2

6 AWG 25 mm

2

4 AWG

500 24 10 mm

2

8 AWG 10 mm

2

8 AWG

800 12 16 mm

2

6 AWG 25 mm

2

4 AWG

800 24 10 mm

2

8 AWG 10 mm

2

8 AWG

1000 12 25 mm

2

4 AWG 35 mm

2

0 AWG

1000 24 16 mm

2

6 AWG 25 mm

2

4 AWG

ATTENTION! Always disconnect electrical power to the anchor windlass before carrying out any operation.

1

2

3

UP

Loading...

Loading...