MAN B&W 14.05

Page 1 of 2

MAN Diesel

198 76 90-8.1MAN B&W S42MC, S35MC, L35MC, S26MC

The air side of the scavenge air cooler can be

cleaned by injecting a grease dissolving media

through ‘AK’ to a spray pipe arrangement fitted to

the air chamber above the air cooler element.

Drain from water mist catcher

Sludge is drained through ‘AL’ to the drain water

collecting tank and the polluted grease dissolvent

returns from ‘AM’, through a filter, to the chemical

cleaning tank. The cleaning must be carried out

while the engine is at standstill.

The ‘AL’ drain line is, during running, used as a

permanent drain from the air cooler water mist

catcher. The water is led through an orifice to pre-

vent major losses of scavenge air.

The system is equipped with a drain box with a

level switch, indicating any excessive water level.

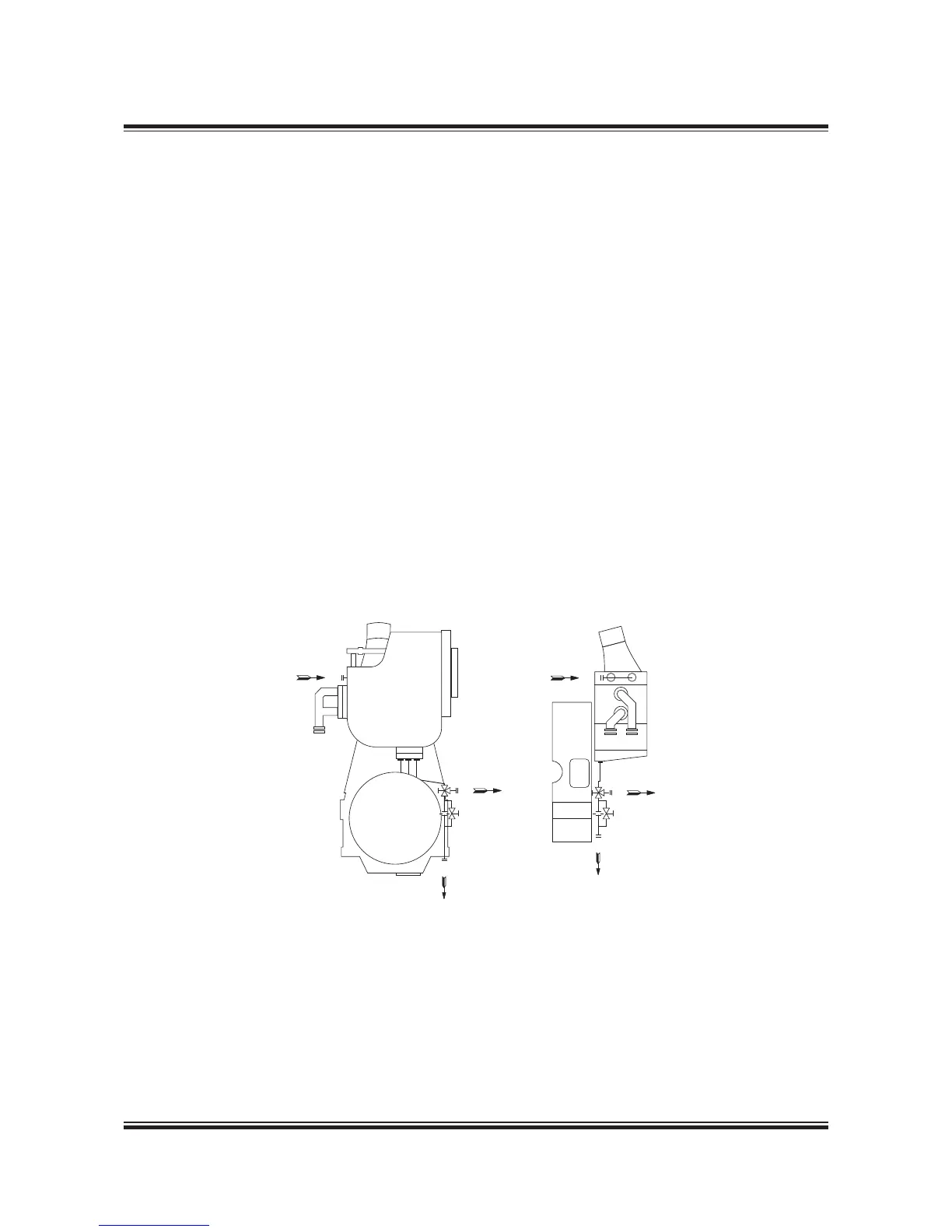

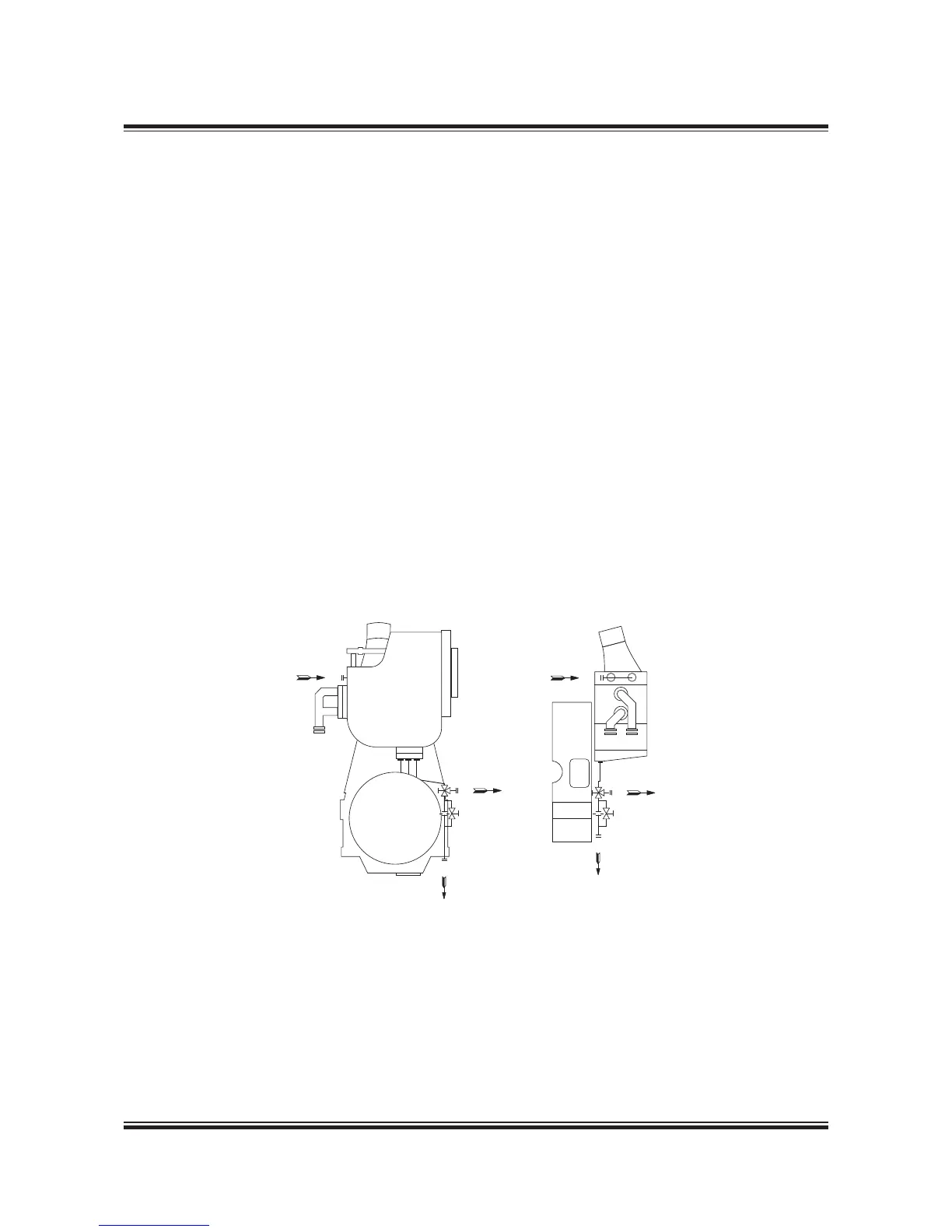

The piping delivered with and fitted on the engine

is shown in Fig 14.05.01.

Auto Pump Overboard System

It is common practice on board to lead drain wa-

ter directly overboard via a collecting tank. Before

pumping the drain water overboard, it is recom-

mended to measure the oil content. If above

15ppm, the drain water should be lead to the

clean bilge tank / bilge holding tank.

If required by the owner, a system for automatic

disposal of drain water with oil content monitoring

could be built as outlined in Fig. 14.05.02.

The letters refer to list of ‘Counterflanges‘

The item no refer to ‘Guidance values automation’

Fig. 14.05.01: Air cooler cleaning pipes, shown on engine with turbocharger located on aft end

Scavenge Air Cooler Cleaning System

AKAK

AL

AMAM

AL

509 69 87-2.0.1

Loading...

Loading...