MAN B&W 15.04

Page 1 of 2

MAN Diesel

198 40 758.7MAN B&W MC/MCC, ME/MEC/MEGI/ME-B engines

Components of the Exhaust Gas System

Exhaust gas boiler

Engine plants are usually designed for utilisation of

the heat energy of the exhaust gas for steam pro-

duction or for heating the thermal oil system. The

exhaust gas passes an exhaust gas boiler which is

usually placed near the engine top or in the funnel.

It should be noted that the exhaust gas tempera-

ture and flow rate are influenced by the ambient

conditions, for which reason this should be con-

sidered when the exhaust gas boiler is planned. At

specified MCR, the maximum recommended pres-

sure loss across the exhaust gas boiler is normally

150 mm WC.

This pressure loss depends on the pressure losses

in the rest of the system as mentioned above.

Therefore, if an exhaust gas silencer/spark ar-

rester is not installed, the acceptable pressure loss

across the boiler may be somewhat higher than the

max. of 150 mm WC, whereas, if an exhaust gas

silencer/spark arrester is installed, it may be neces-

sary to reduce the maximum pressure loss.

The above mentioned pressure loss across the

exhaust gas boiler must include the pressure

losses from the inlet and outlet transition pieces.

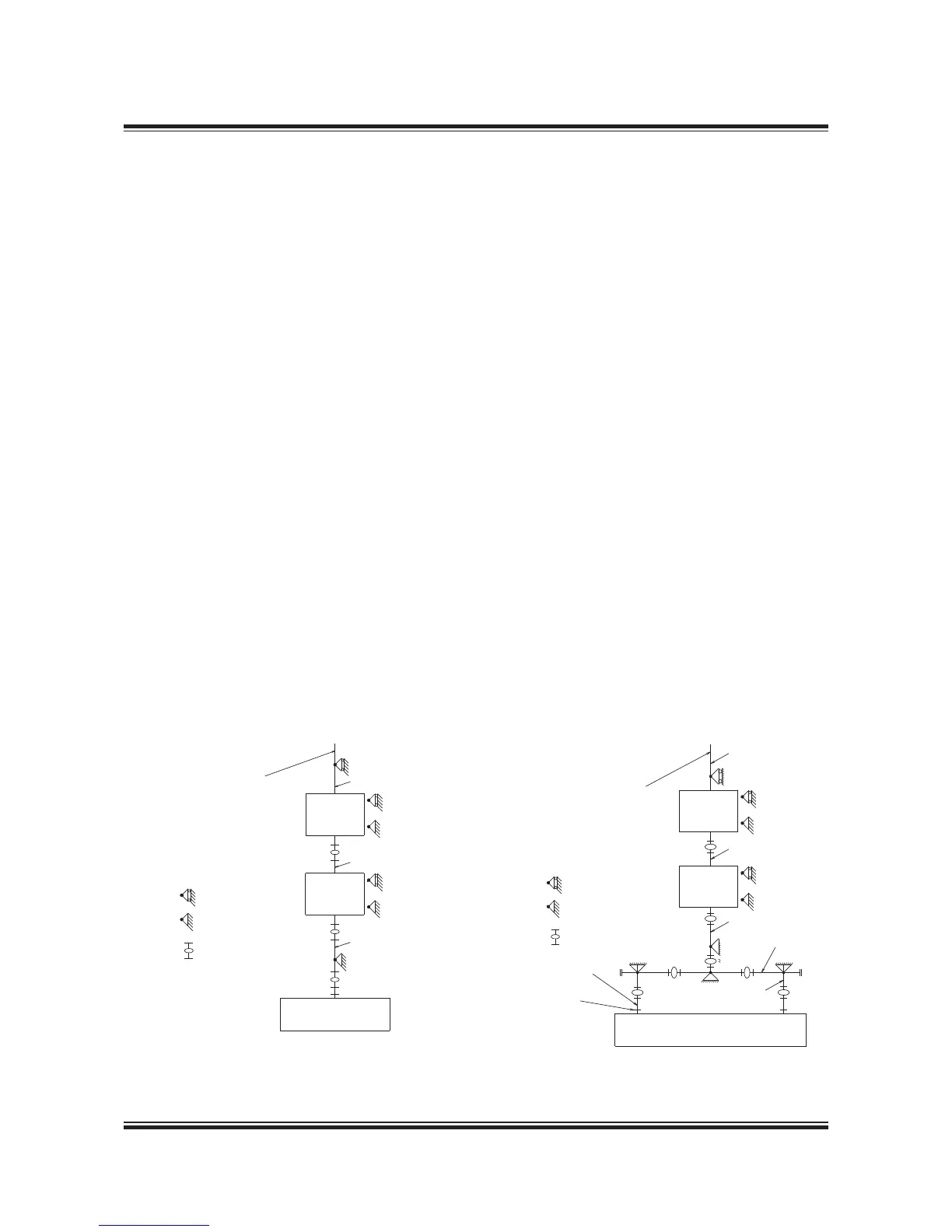

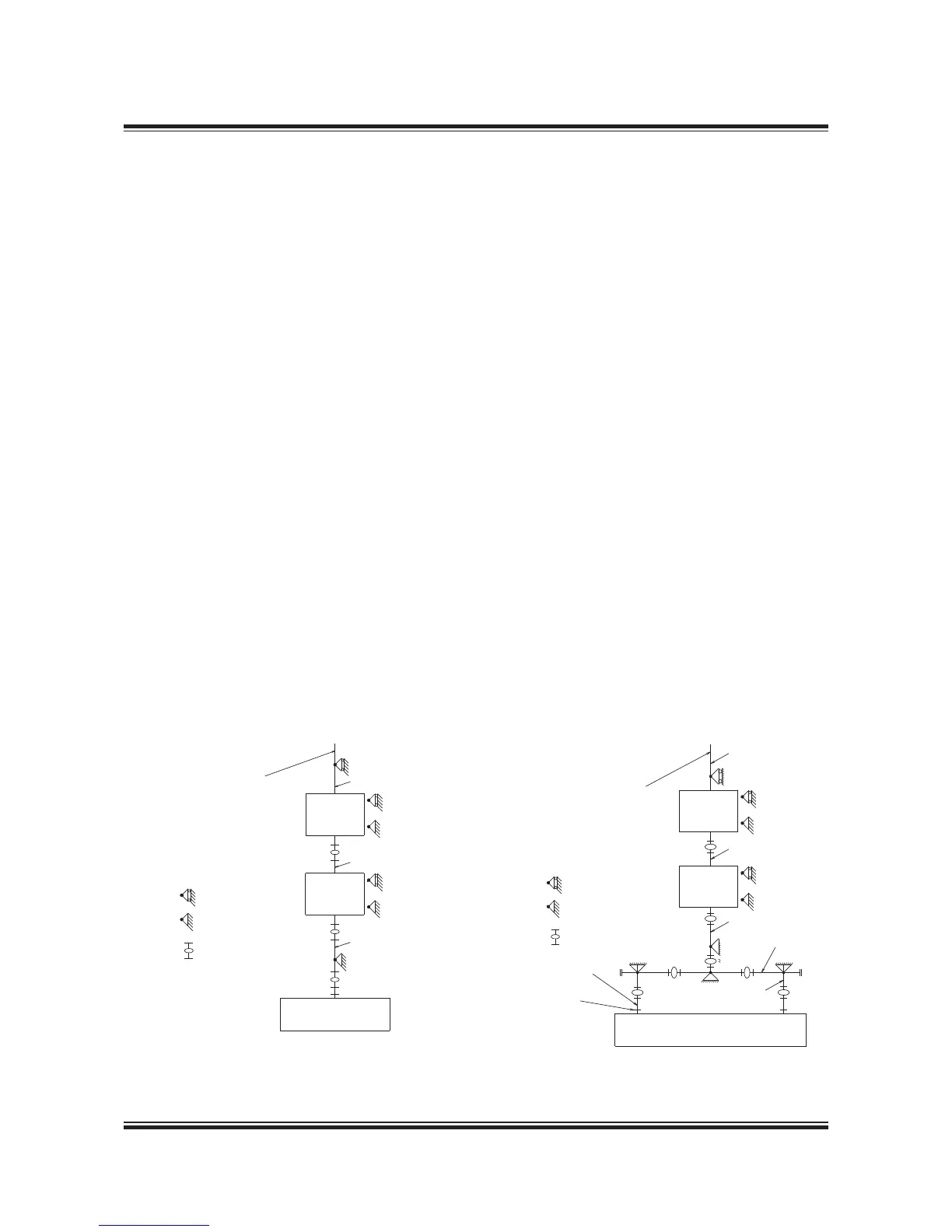

Fig. 15.04.01a: Exhaust gas system, one turbocharger

178 42 783.2

Exhaust gas compensator after turbocharger

When dimensioning the compensator, option:

4 60 610, for the expansion joint on the turbochar-

ger gas outlet transition piece, option: 4 60 601,

the exhaust gas piece and components, are to be

so arranged that the thermal expansions are ab-

sorbed by expansion joints. The heat expansion of

the pipes and the components is to be calculated

based on a temperature increase from 20 °C to

250 °C. The max. expected vertical, transversal

and longitudinal heat expansion of the engine

measured at the top of the exhaust gas transition

piece of the turbocharger outlet are indicated in

Fig. 15.06.01 and Table 15.06.02 as DA, DB and DC.

The movements stated are related to the engine

seating, for DC, however, to the engine centre. The

figures indicate the axial and the lateral movements

related to the orientation of the expansion joints.

The expansion joints are to be chosen with an elas-

ticity that limits the forces and the moments of the

exhaust gas outlet flange of the turbocharger as

stated for each of the turbocharger makers in Table

15.06.04. The orientation of the maximum permis-

sible forces and moments on the gas outlet flange

of the turbocharger is shown in Fig. 15.06.03.

Loading...

Loading...