76 647852EN-USM1(B-12/2021)

MAINTENANCE

4.8.4 CLEAN DRY AIR FILTER

CARTRIDGE

NOTICE

The cartridge must not be cleaned more than seven times,

after which the cartridge must be changed. Never operate

the lift truck with the air filter removed or damaged.

NOTICE

Respect the safety distance of 30mm between the air jet

and the cartridge to avoid tearing or making a hole in

the cartridge. The cartridge must not be blown

anywhere near the air filter box. Never clean the

cartridge by tapping it against a hard surface. Your eyes

must be protected during this intervention.

NOTICE

Do not clean the dry air filter cartridge by washing it in

liquid. Do not clean by any means the safety cartridge

located inside the filter cartridge, change it for a new one if

it is dirty or damaged.

In case of use in a heavily dust laden

atmosphere, the cartridge inspection and

cleaning frequency must be reduced.

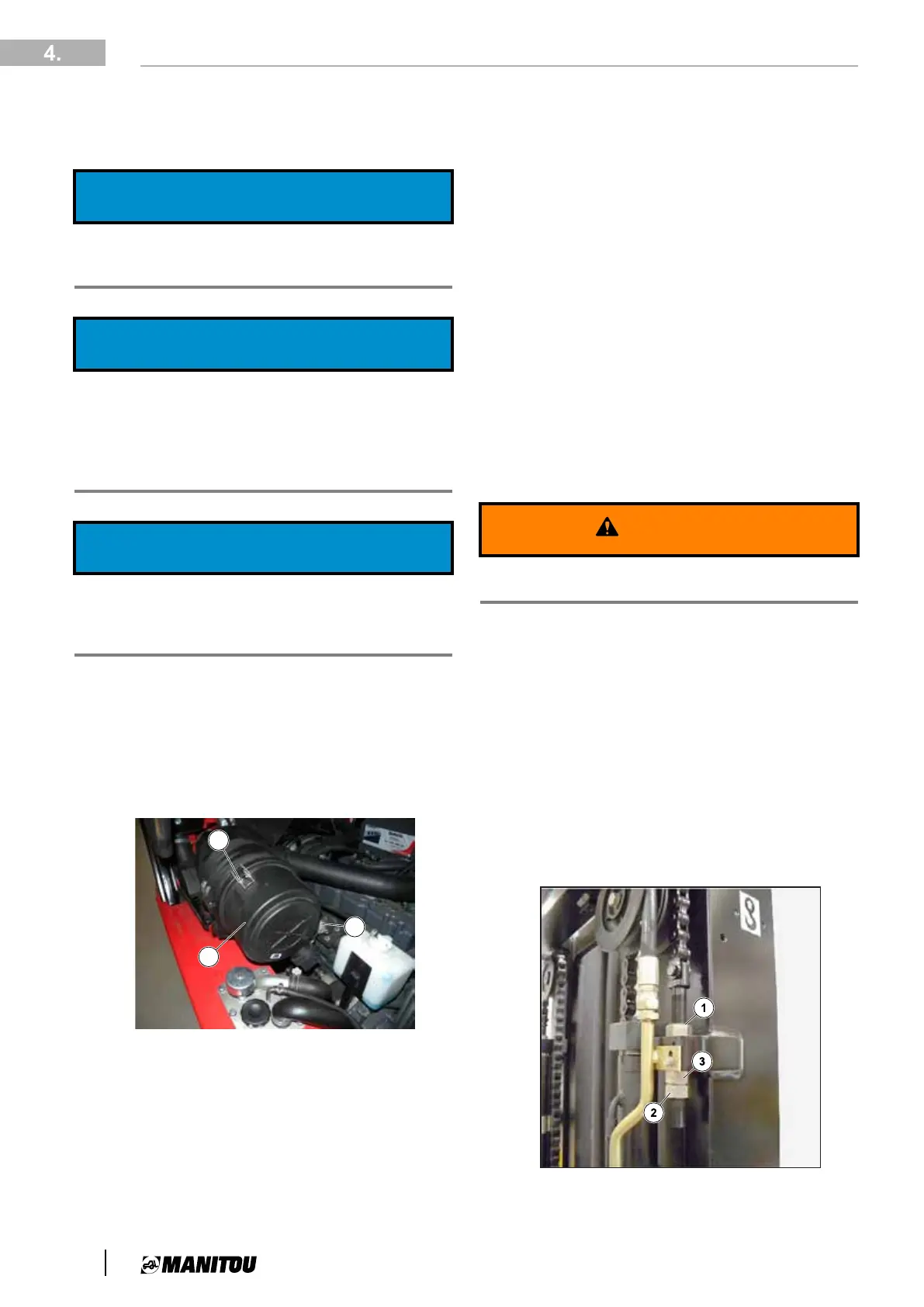

1. Raise the engine cover.

2. Release the bolts (1) and remove cover (2).

3. Clean the filter cartridge using a compressed air jet

(max. pressure 3 bar) directed from the top to the

bottom and from the inside towards the outside at a

minimum distance of 30 mm from the cartridge wall.

4. Cleaning is completed when there is no more dust

on the cartridge.

5. Clean the cartridge seal surfaces with a damp,

clean lint-free cloth and grease with a silicone

lubricant (MANITOU reference: 479292).

6. Check visually the outer condition of the air filter

and its mounts. Verify the condition of the hoses

and their mounts also.

4.8.5 CHECK WHEEL NUT TORQUES

1. Check the condition of the tyres, to detect cuts,

protuberances, wear, etc.

2. Check the torque load of the wheel nuts. Non

compliance with this instruction can cause damage

and rupture to the wheel bolts and distortion to the

wheels.

4.8.6 CHECK-ADJUST TENSION

AND ALIGNMENT OF MAST LIFTING

CHAINS

WARNING

These checks are important for the good working operation

of the mast. In case of technical faults, consult your dealer.

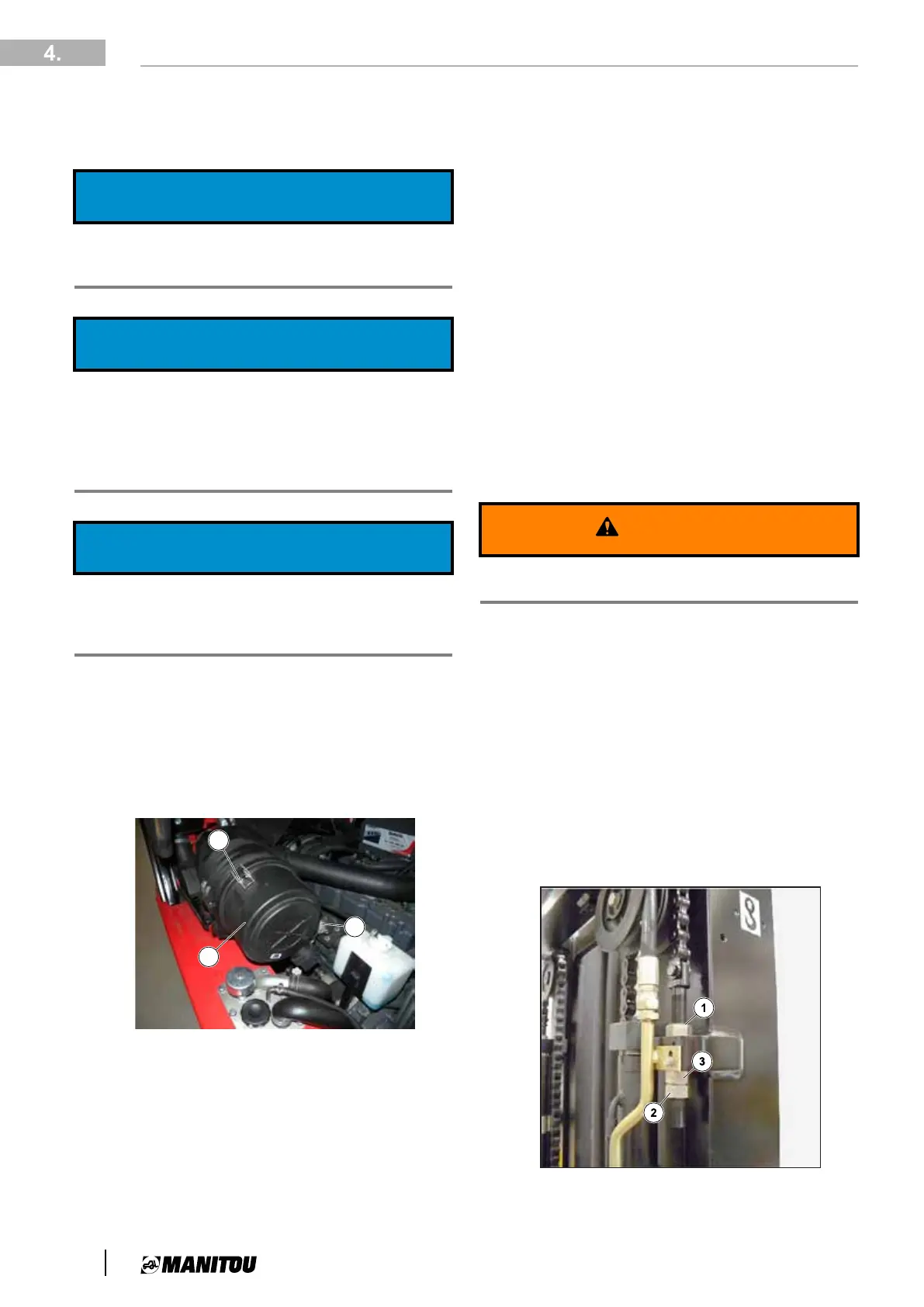

Place the lift truck on level ground with the mast

in a vertical position and the forks raised

approximately 200 mm.

1. Visually check the state of the mast and the forks.

2. Check the alignment of the mast lifting chains

between the carriage’s chain fasteners and the

chain rollers.

3. Manually verify the chain tension, if necessary

adjust as following while ensuring that the carriage

is perpendicular to the mast.

4. Loosen the nut (1).

4.

Loading...

Loading...