HYDRAULIC SYSTEM 5540F/YB5515 SERVICE MANUAL

4-14 Published 10-21-2010, Control# 198-04

Parallel Valve Spool Description

A parallel spool is a solid-core spool designed to route oil

from the work circuit back to tank.

In a valve assembly that has all parallel valve spools, if two

are shifted at the same time, the spool closest to the valve

inlet will block the open-center passage and prevent supply

oil from reaching the other spools downstream. If the first

spool is shifted to only partially block the center passage, the

oil will enter the work circuit which offers the least resistance.

Oil always flows the path of least resistance. When two

parallel spools are shifted at the same time, the function

which offers the least resistance will move first. When the

resistance in that circuit increases above that of the circuit,

the second function will operate. In affect, with a parallel

spool arrangement, only one function is workable at a time.

Main Relief And Port Relief Valves

The main relief valves for the main system are located in the

inlet sections of the main control valve. The relief valve is in

communication with the center or high pressure passage of

the control valve and will open to release excess oil to tank

when the pressure in the center passage exceeds the

pressure setting of the main relief valve.

The purpose of the main relief valve is to control maximum

pressure in the pumping circuits and to control any pressure

surges or spikes caused by a sudden load on the system.

Since pressure applied to any point in the circuit is applied

equally through the circuit, a pressure surge at a motor or

cylinder is felt all the way back to the pump.

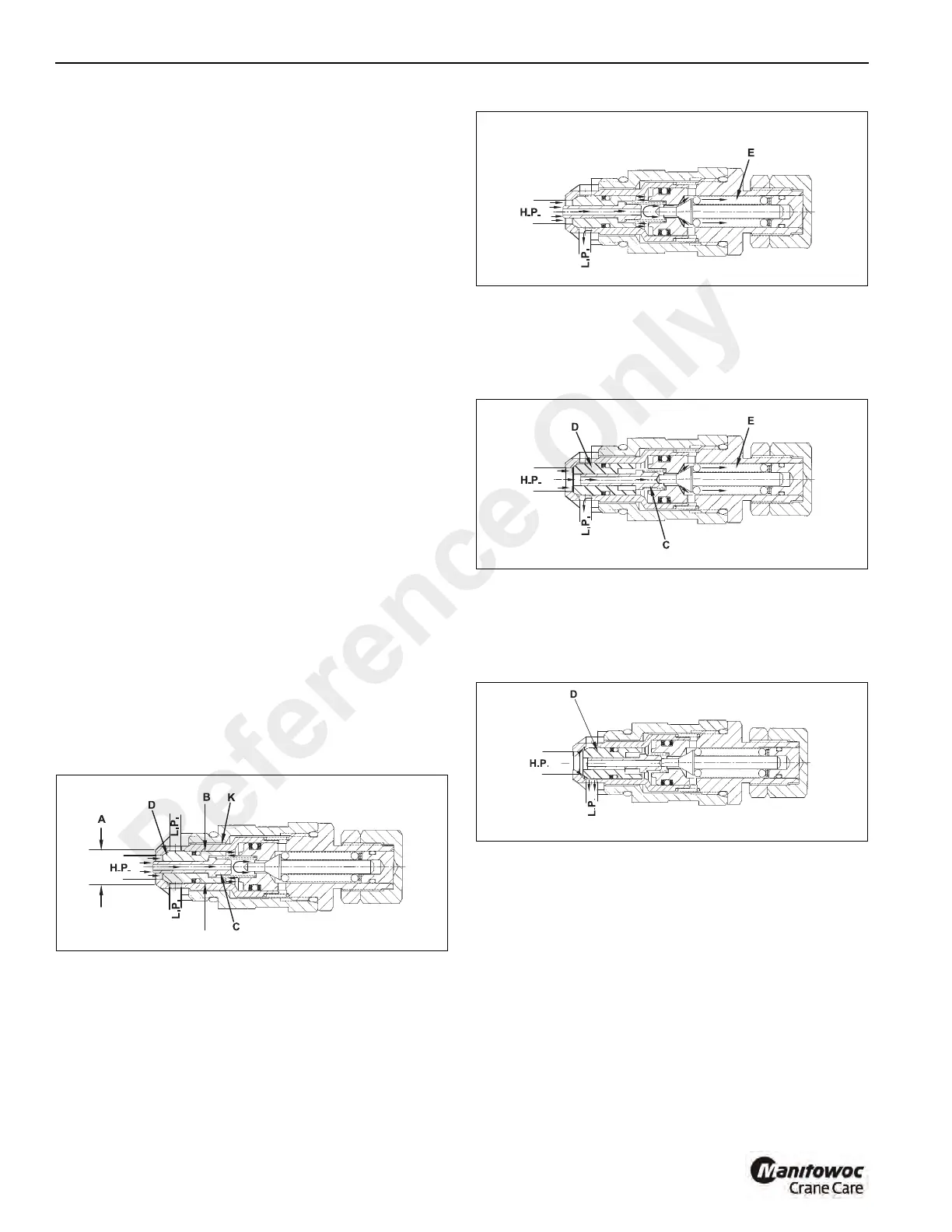

A relief valve is in communication between the high pressure

port “HP” Figure 4-10 and the low pressure area “LP”. Oil is

admitted through the hole in poppet “C” and because of a

differential area between diameters “A” and “B”, relief valve

poppet “D” and check valve poppet “K” are tightly sealed.

The oil pressure in the high pressure port “HP” Figure 4-11

has reached the setting of the pilot poppet spring force and

unseats pilot poppet “E” and oil flows around the poppet,

through the cross drilled holes and to the low pressure area

“LP”.

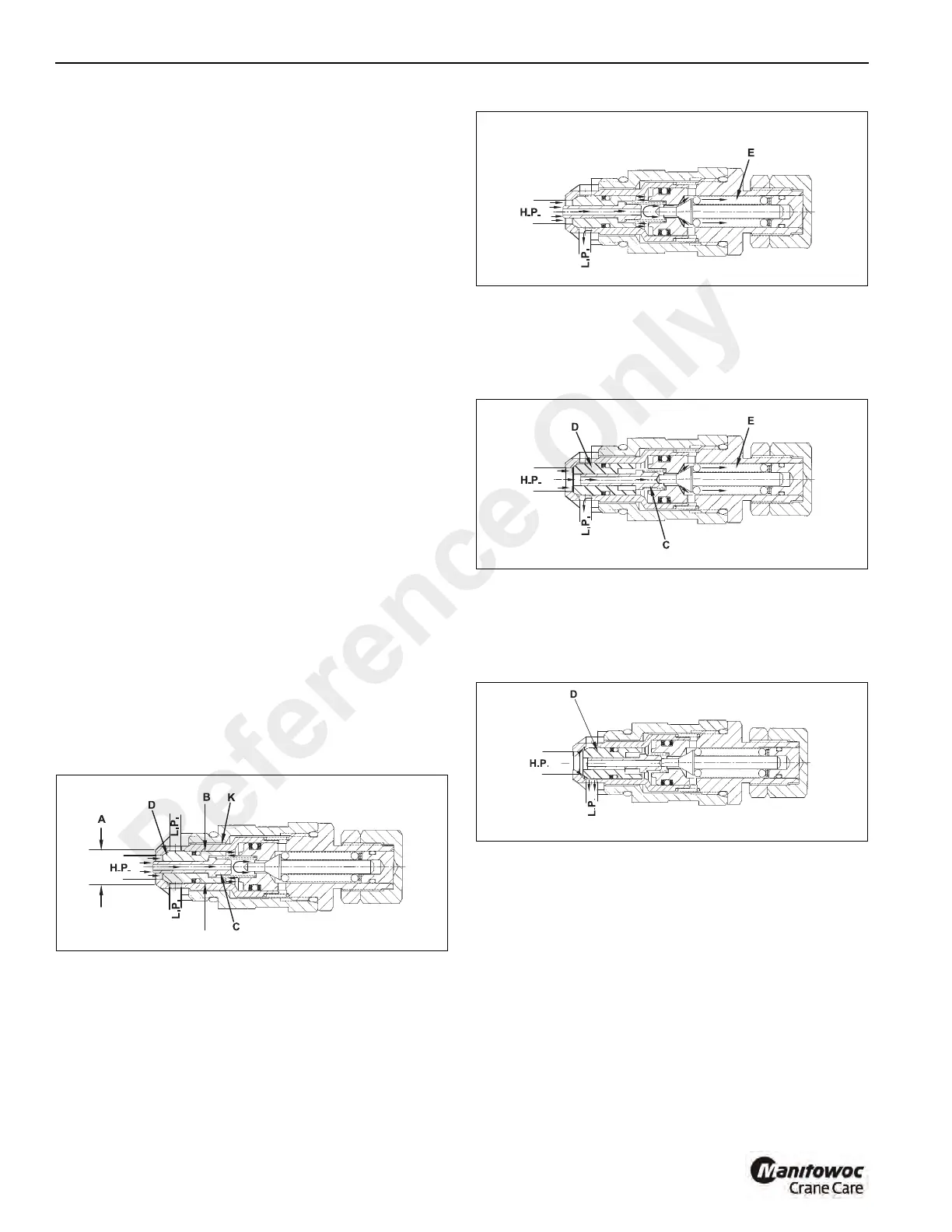

The loss of oil behind poppet “C” Figure 4-12 affected by the

opening of pilot poppet “E” causes poppet “C” to move back

and seat against pilot poppet “E”. This shuts off the oil flow to

the area behind relief valve poppet “D” and causes a low

pressure area internally.

The imbalance of pressure on the inside as compared to that

of the high pressure port “HP” forces the relief valve poppet

“D” Figure 4-13 to open and relieve the oil directly to the low

pressure chamber “LP” in the valve. Oil then flows back to

the hydraulic oil tank.

Main Relief Valve Pressure Test Procedure

NOTE: The hydraulic oil must be at operating temperature

(120° - 130° F (45° - 54° C).

Swing Circuit Main Relief Valve Setting Test

1. With the engine shut off and parking brake engaged,

install a 0 - 5000 psi (0 - 345 bar) pressure gauge to the

test connection on the pressure side of the swing section

of the hydraulic pump (Figure 4-14).

2. Disconnect both hoses at the swing motor. Plug the

hoses and cap the fittings on the motor.

3. Start the engine and accelerate it to full rpm.

Reference Only

Loading...

Loading...