• DOK-DIAX02-DDS02.1*ANA-ANW1-EN-E1,44 • 12.96

12

ENA3A-Abb0.25/InbetrDDS

X

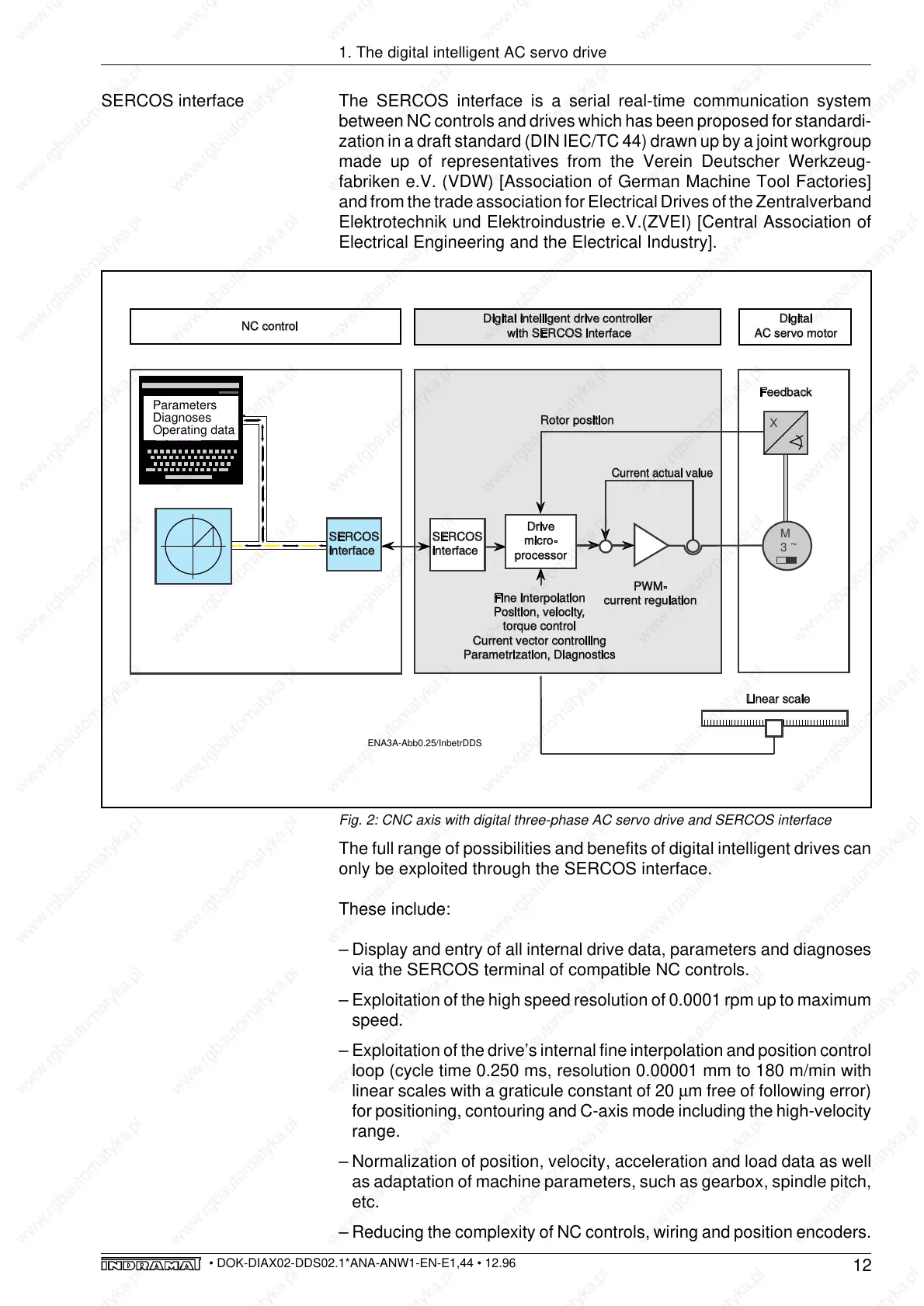

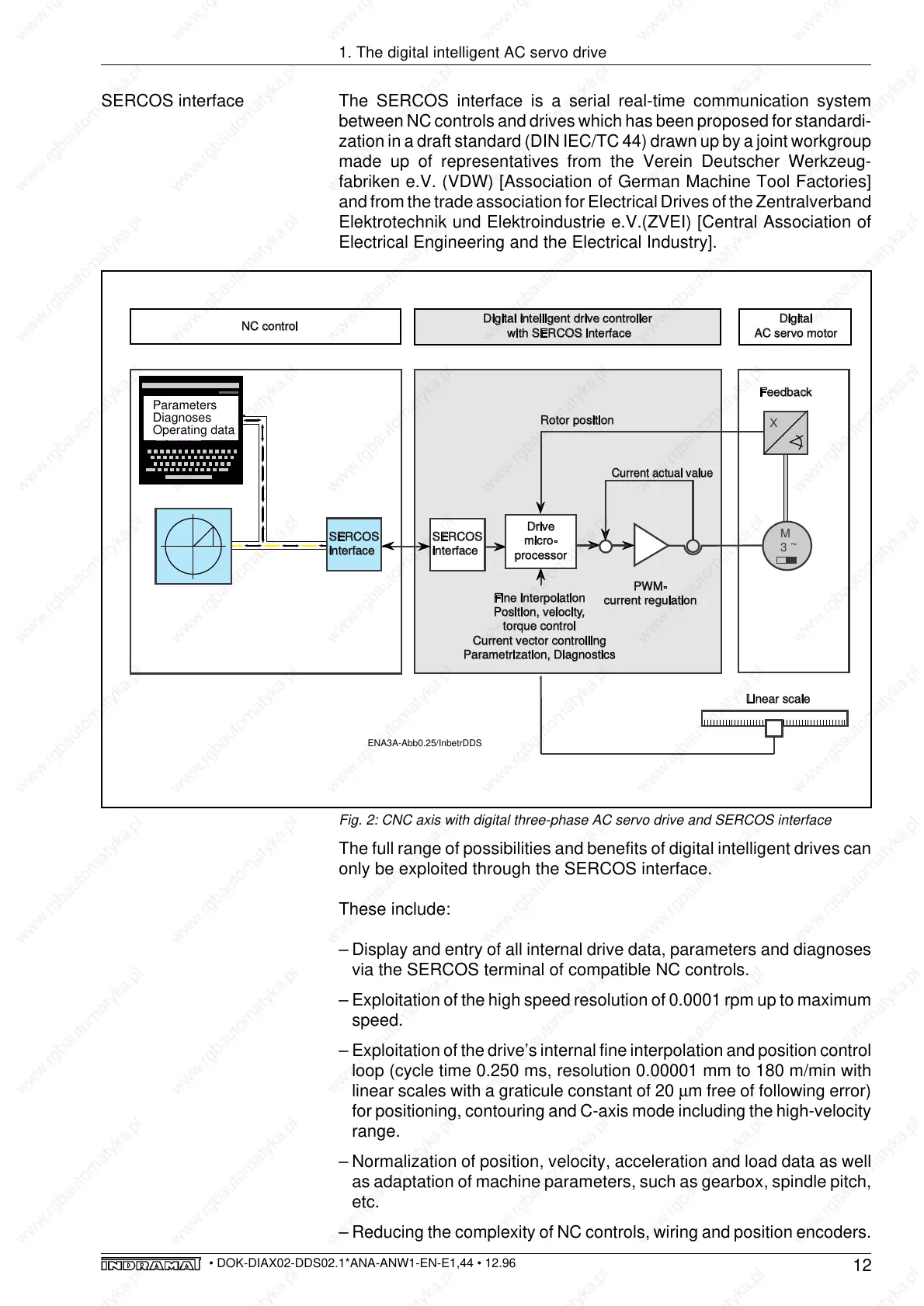

SERCOS

interface

M

3

~

SERCOS

interface

Fine interpolation

Position, velocity,

torque control

Current vector controlling

Parametrization, Diagnostics

PWM-

current regulation

Current actual value

NC control

Digital intelligent drive controller

with SERCOS interface

Digital

AC servo motor

Rotor position

Feedback

Drive

micro-

processor

Linear scale

234554

Zum Mech

Überblick

1

Parameters

Diagnoses

Operating data

The SERCOS interface is a serial real-time communication system

between NC controls and drives which has been proposed for standardi-

zation in a draft standard (DIN IEC/TC 44) drawn up by a joint workgroup

made up of representatives from the Verein Deutscher Werkzeug-

fabriken e.V. (VDW) [Association of German Machine Tool Factories]

and from the trade association for Electrical Drives of the Zentralverband

Elektrotechnik und Elektroindustrie e.V.(ZVEI) [Central Association of

Electrical Engineering and the Electrical Industry].

SERCOS interface

Fig. 2: CNC axis with digital three-phase AC servo drive and SERCOS interface

1. The digital intelligent AC servo drive

The full range of possibilities and benefits of digital intelligent drives can

only be exploited through the SERCOS interface.

These include:

– Display and entry of all internal drive data, parameters and diagnoses

via the SERCOS terminal of compatible NC controls.

– Exploitation of the high speed resolution of 0.0001 rpm up to maximum

speed.

– Exploitation of the drive’s internal fine interpolation and position control

loop (cycle time 0.250 ms, resolution 0.00001 mm to 180 m/min with

linear scales with a graticule constant of 20 µm free of following error)

for positioning, contouring and C-axis mode including the high-velocity

range.

– Normalization of position, velocity, acceleration and load data as well

as adaptation of machine parameters, such as gearbox, spindle pitch,

etc.

– Reducing the complexity of NC controls, wiring and position encoders.

Loading...

Loading...