13 Malfunctions

72

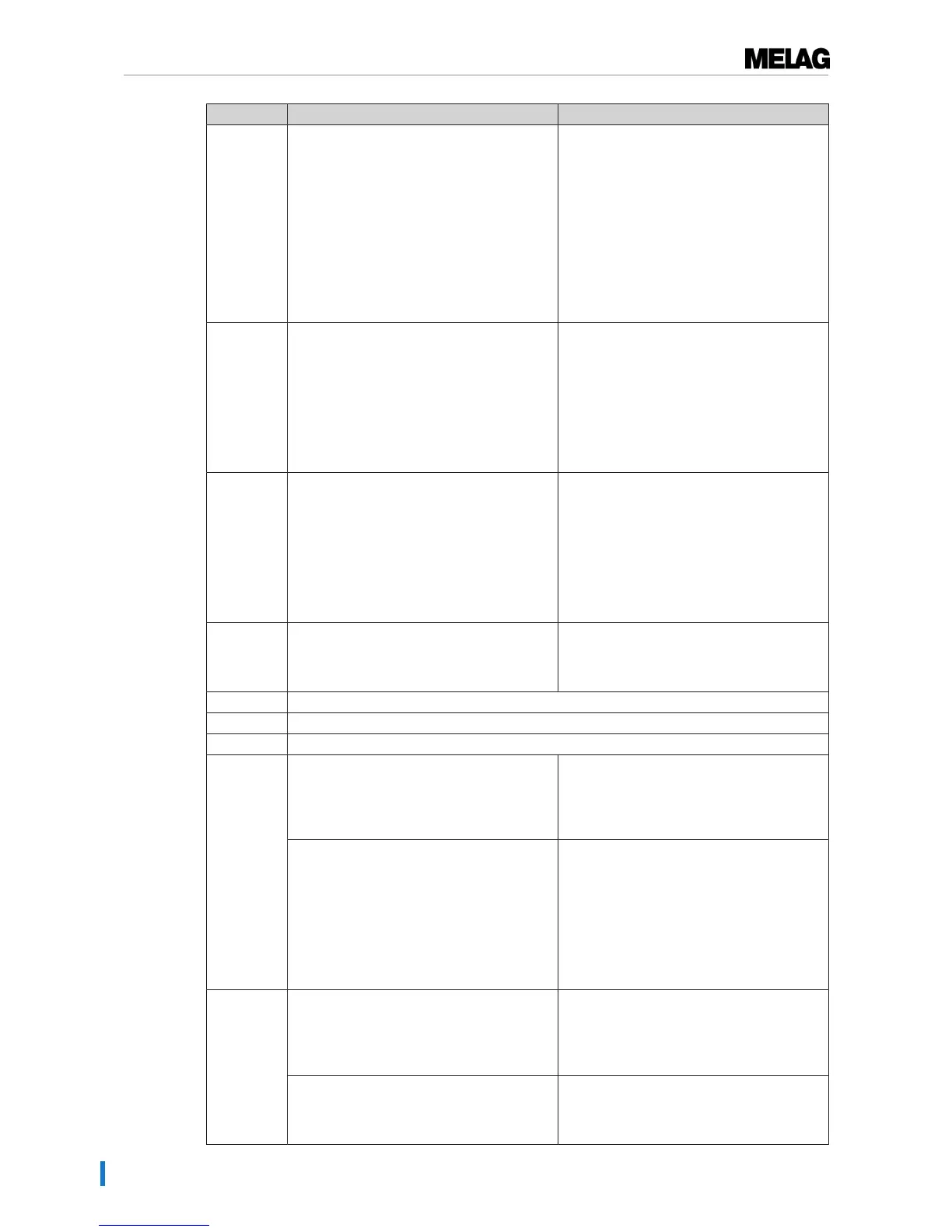

Incident Possible causes What you can do

136 a) The surrounding temperature of the steam

sterilizer is too hot.

b) The ventilation slots in the side walls are

clogged/blocked.

c) The steam sterilizer is installed. The

minimum clearance to the surrounding

surfaces has not been maintained.

d) The door was left open after loading or

unloading and hot steam has escaped from

the sterilization chamber.

Switch off the steam sterilizer and allow it to

cool for c. 1 hour.

a) Comply with the requirements at the

installation location and the maximum

ambient temperature (see technical manual).

b) Clean the ventilation slots and remove any

objects covering them.

c) Maintain a minimum clearance to the

surrounding surfaces (see information in the

technical manual).

d) Always close the door after loading or

unloading.

175 The overheat control switch of the main

heating has tripped. This notification may be

issued in alternation with “E176: ACOUT 02

open".

1. Switch off the steam sterilizer and press

the reset button overheat control on the fore

side of the steam sterilizer at the bottom

right-hand side (behind the cover) back in.

2. Acknowledge the malfunction message.

3. Switch off the steam sterilizer and back on

again and then perform an empty sterilization

run if necessary. Then the steam sterilizer is

ready for operation.

176 The overheat control switch of the main

heating has tripped. This notification may be

issued in alternation with “E175: ACOUT 01

open".

1. Switch off the steam sterilizer and press

the reset button overheat control on the fore

side of the steam sterilizer at the bottom

right-hand side (behind the cover) back in.

2. Acknowledge the malfunction message.

3. Switch off the steam sterilizer and back on

again and then perform an empty sterilization

run if necessary. Then the steam sterilizer is

ready for operation.

182 The mains voltage is too low, poor building

voltage supply (e.g. undersized installation,

defective socket, multiple devices on a single

socket/fuse).

Arrange for an inspection of the building-side

installation (e.g. automatic circuit breaker)

and test the steam sterilizer at another

socket or on another circuit.

183 see event 124

185 see event 110

186 see event 110

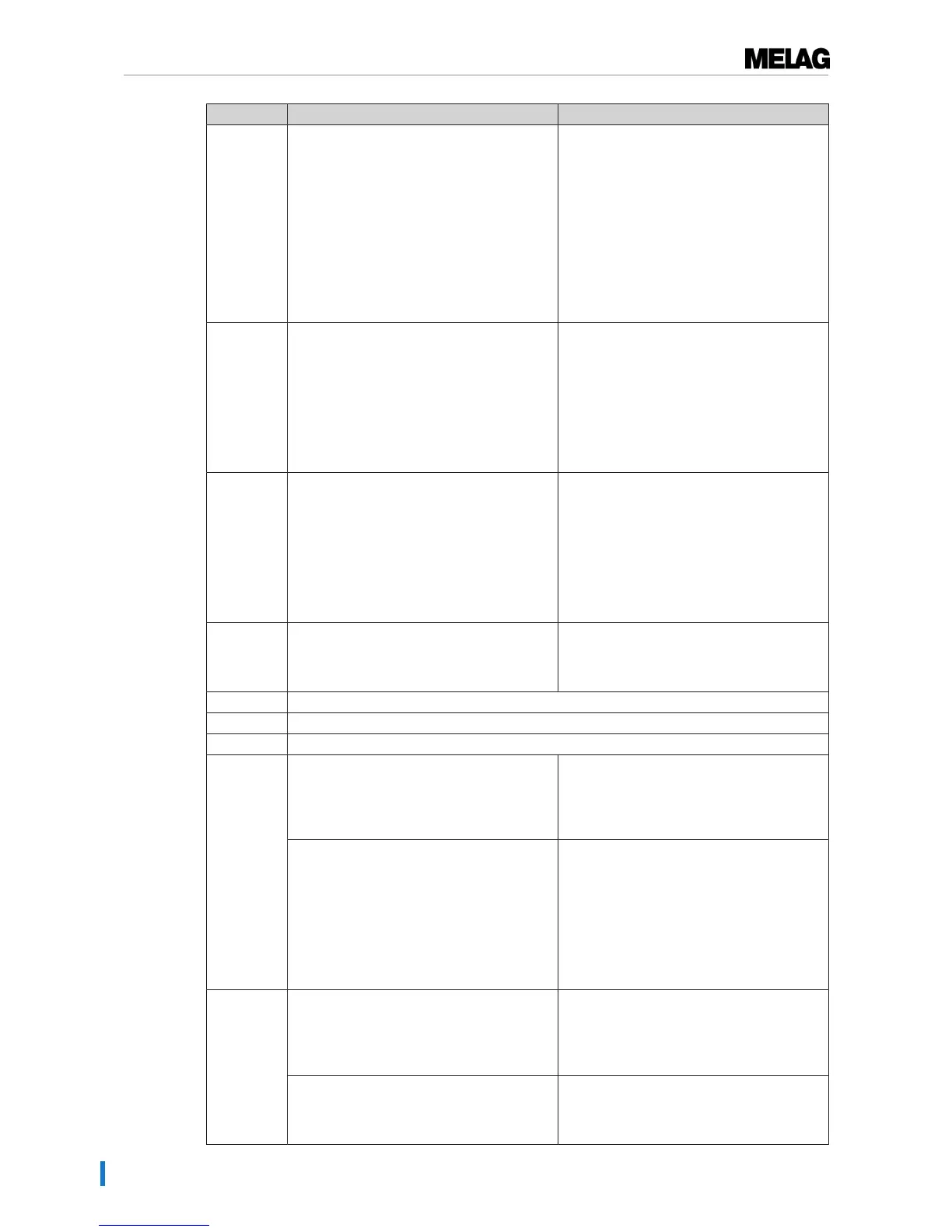

187 a) The chamber filter “Pressure release” is

blocked.

a) Remove the "Pressure release” chamber

filter (in the rear area of the sterilization

chamber below) and check whether it is e.g.

soiled/blocked by packaging. If necessary,

clean the chamber filter.

With connection to the building waste water

outflow:

The waste water cannot flow off.

b) The waste water hose is kinked or

installed sagging.

c) The siphon or the building-side waste

water line is blocked.

With connection to the building waste water

outflow:

b) Check the installation of the waste water

hose. This must be installed without kinking

or sagging and at a constant decline.

c) Check whether the building siphon is

blocked. Please note: If multiple devices are

operated simultaneously, we recommend the

installation of an additional siphon.

192 When using the internal storage tank:

a) The right-hand chamber of the internal

storage tank (feed water) must be sufficiently

filled with feed water for the pending rinsing

process.

a) Check the water level of the feed water in

the right-hand chamber of the internal

storage tank and refill with feed water if

necessary.

When using a MELAG water treatment unit:

b) The pending feed water procedure

requires sufficient supply with feed water.

b) Check whether the water inflow tap for the

water treatment unit is open. When using a

MELAdem 47, check whether the tap on the

pressure tank is open.

Loading...

Loading...