8 - 29 8 - 29

MELSEC-Q

8 TROUBLESHOOTING

(3) Storage of the error codes of the link dedicated instruction

Check the error code generated when the link dedicated instruction is executed

through the device data below.

The error codes of the transient transmission are also stored in the link special

registers SW00EE to SW0FF.

For the details of the REMFR/REMTO instruction, refer to the description on the

programming of link dedicated instructions in section 7.1.1.

For details about READ/WRITE instructions, refer to the Q-corresponding

MELSECNET/H network system reference manual (PLC to PLC network).

1) REMFR, REMTO

· · · · · · ·

SW31 (When channel 1 is used)

SW33 (When channel 2 is used)

SW35 (When channel 3 is used)

SW37 (When channel 4 is used)

SW39 (When channel 5 is used)

SW3B (When channel 6 is used)

SW3D (When channel 7 is used)

SW3F (When channel 8 is used)

3) READ, WRITE

· · · · · · ·

Control data completion status (S1) +1

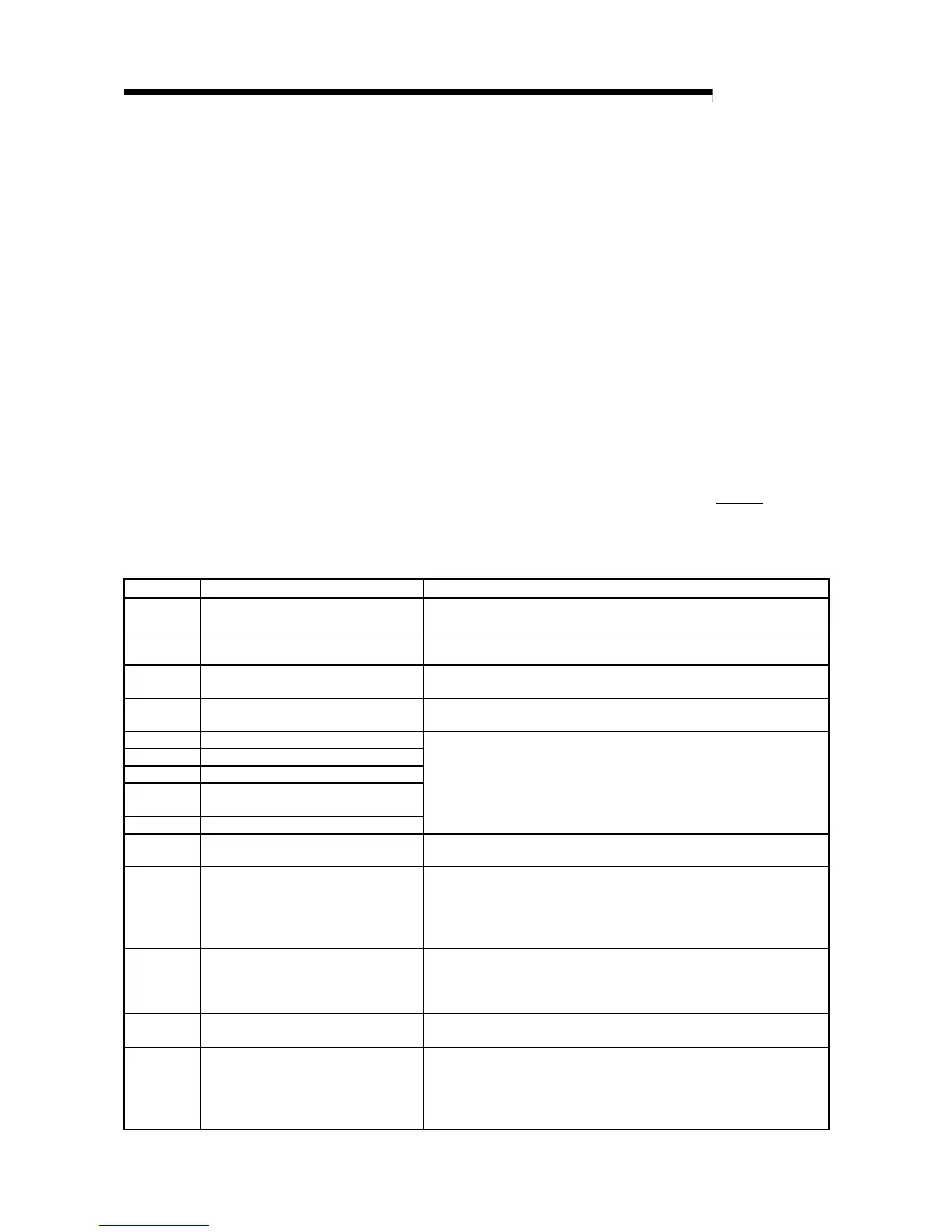

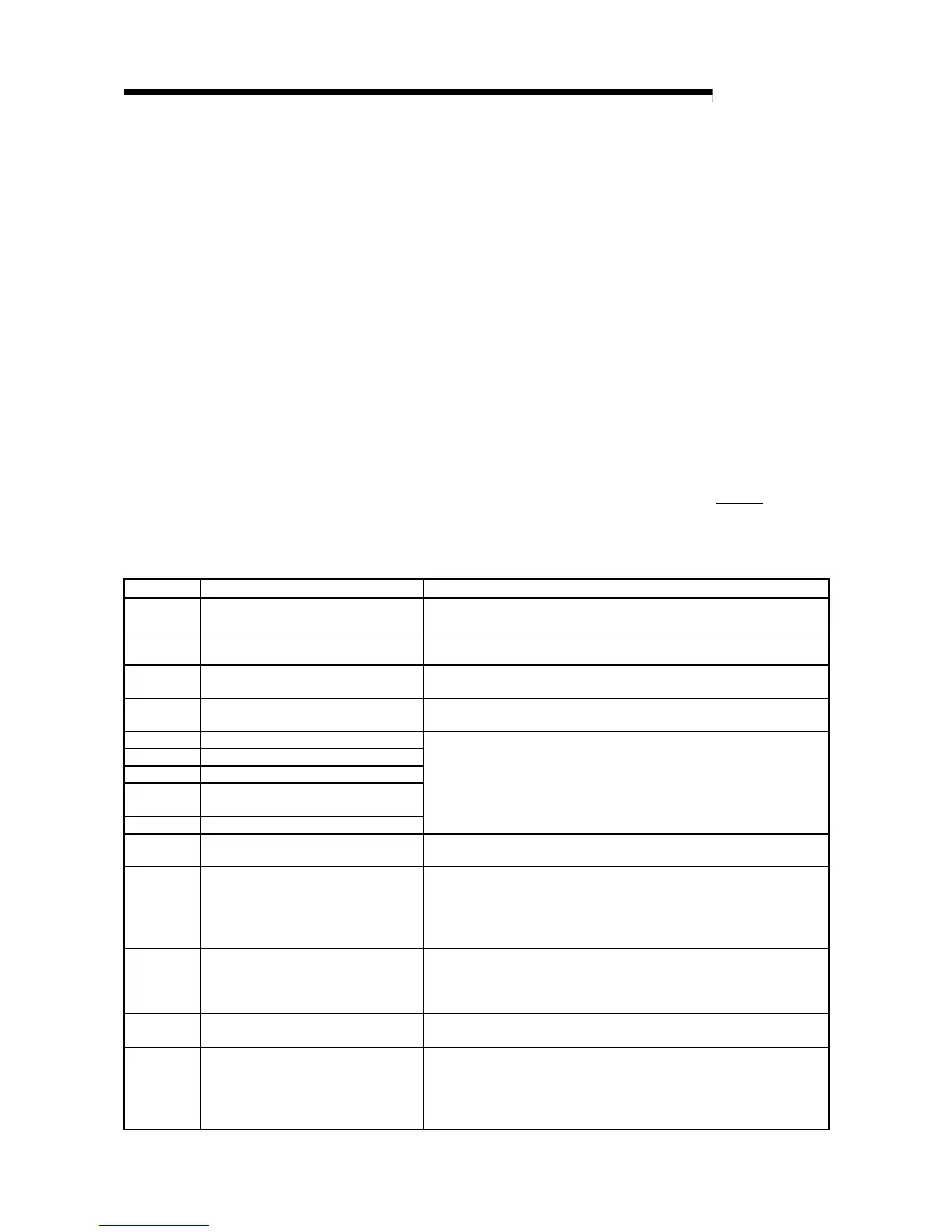

(4) Table 8.1 lists the descriptions of error codes.

Table 8.1 Error code list

Error No. Description of error Corrective measure

4000 to 4FFF (Error detected by the PLC CPU)

Take measures referring to the troubleshooting section of the QCPU User's

Manual (Hardware Design, Maintenance and Inspection).

7000 to 7FFF

(Error detected by the serial

communication module, etc.)

Take measures referring to the troubleshooting section of the Serial

Communication Module User's Manual.

B000 to BFFF (Error detected by the CC-Link module)

Take measures referring to the troubleshooting section of the CC-Link System

Master/Local Module User's Manual.

C000 to CFFF (Error detected by the Ethernet module)

Take measures referring to the troubleshooting section of the Ethernet Interface

Module User's Manual.

F101 Initial status (Network activated)

F102 Initial status (Network activated)

F103 Initial status (during online test)

F104

Initial status

(Control/sub-control station shift)

F105 Initial status (Parameters being processed)

Wait until SB0047 (baton pass status) and SB0049 (data link status) turn off

(normal).

F106

Shift from failed control station to sub-

control station

Check the condition of the control station's power supply and of the cables and

the status of the control station CPU module.

F107 Baton pass error (baton lost)

Check the line status for a faulty cable or a missing terminating resistor, as well

as the stations that are not powered on.

In the case of the PLC to PLC network, when transient transmission is

executed frequently and the link scan time may exceed 200 ms, adjust the

transient setting values to reduce the link scan time.

F108 Baton pass error (duplicate baton)

Check for duplicate station numbers and control stations with the setup

confirmation test.

Check for faulty cables, wire breakage, poor connector connections, connection

errors, uninstalled or loose terminal resistors, etc.

F109 Initial status (during online test)

Wait until SB0047 (baton pass status) and SB0049 (data link status) are

recovered.

F10A Initial status (online test/offline loop test)

<During execution of an online test>

Wait until SB0047 (baton pass status) and SB0049 (data link status) are

recovered.

<During execution of an offline test>

Change the switch setting to online after the test has been completed.

Loading...

Loading...