USER MANUAL NOVAcompact

MRU GmbH, D-74172 Neckarsulm

5. Maintenance and cleaning

5.1. Cleaning

The analyzer needs to the long value preservation only one very low maintenance need:

• now and then: Cleaning of the probe and the probe tube

• after every measurement: remove gas sampling tube from the analyzer, so that the

hose can dry

• after longer disuse load battery first and afterwards approx. all 4 weeks

• check filter: external filter reconnect for CHP measurements

5.2. Service and Maintenance

• An annual service check and if necessary adjustment of the sensors at an MRU

service department (www.mru.eu

) are recommended for the preservation of value.

• With optional gas detector:

In the case of a use to the pure leakage detection (maximum value search) a function

check of the equipment is enough e.g. over an impact from a search gas bottle. A

long-term continuous detector accuracy is guaranteed however only by an annually

repeated calibration of the equipment.

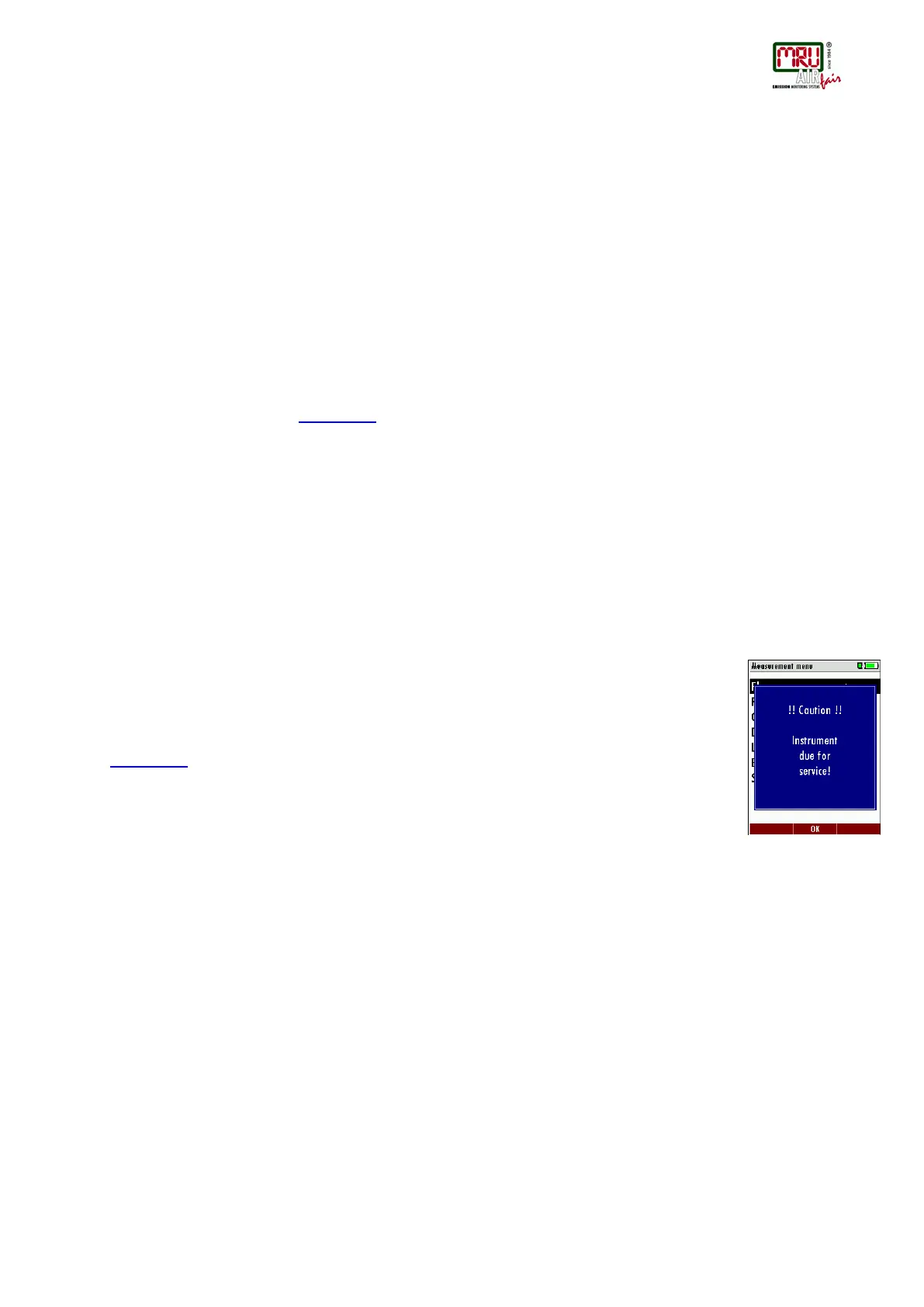

5.3. Service-Maintenance Plan

A check of analyzer at our Service Department is necessary:

• after 1000 working hours or

if it has been more than 11 months since the last check.

When next powered on, you will be remindered to the execution of the annual customer service.

A complete service at a MRU service station (for MRU services station please see:

www.mru.eu

) contains the function control and calibration and/or cleaning of the following

components:

Sensors, pumps, internal/external hose lines, battery, draft sensor, electronics, time and date,

temperature sensors, gas sampling probes, condensate separator

Loading...

Loading...