GB

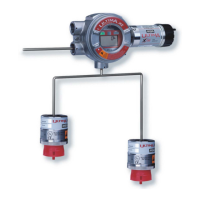

OPTION FOR INTERNAL RELAY MSA

38 ULTIMA

®

X

3 TM

Appendix C Option for internal relay

C-1. Relay connections

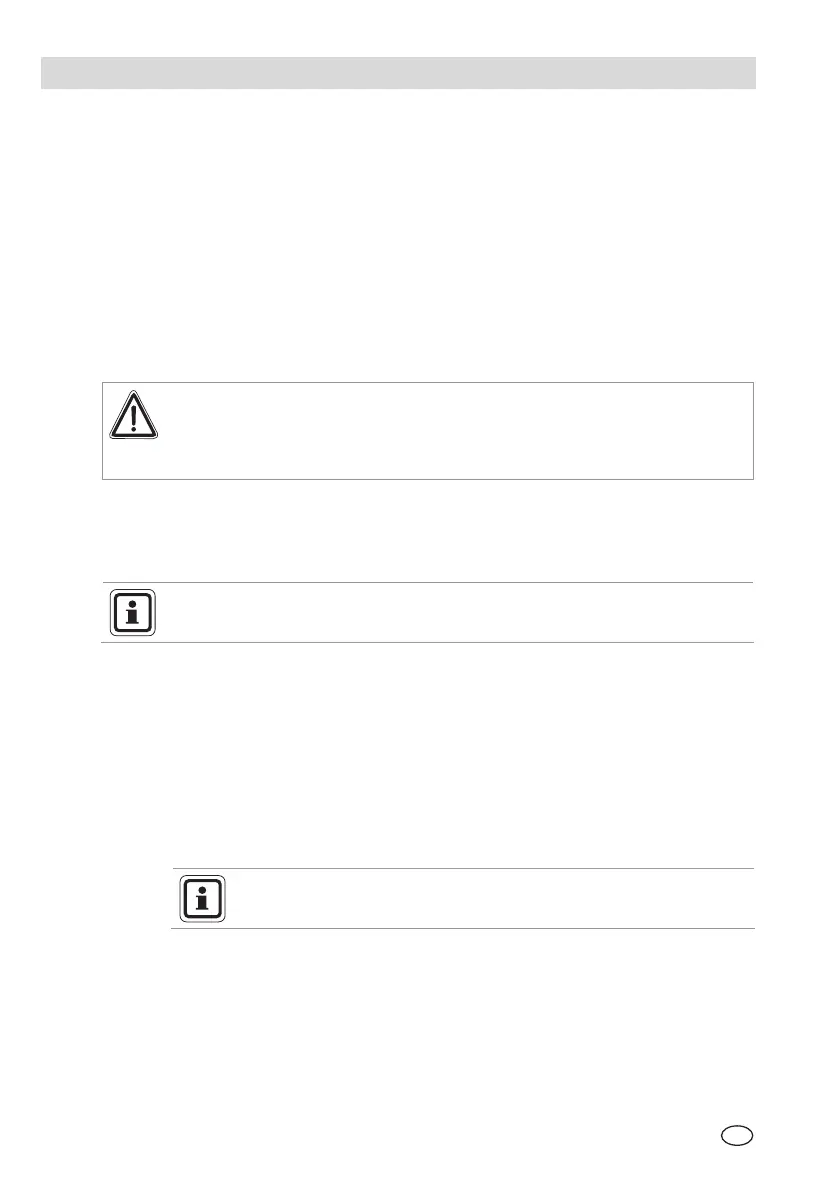

All electrical connections to the internal relays can be made directly on the printed

board (see Figure 4). When connecting the relays to motors, fluorescent lamps or

other inductive loads, it is necessary to suppress any sparks or inductive

feedback that may occur at the relay contact. These effects may damage the

instrument and make it inoperative.

One way to reduce these effects is to install a “Quencharc

®

”, available from MSA

as part number 630413, across the load being switched.

Attention!

Before connecting the cable to ULTIMA

®

X

3 TM

Gas Monitors,

disconnect or isolate , the monitor power source otherwise there is

danger of electric shock.

To connect the relay, the ULTIMA

®

X

3 TM

Gas Monitor must be opened.

Proceed as described below:

(1) Remove the ULTIMA

®

X

3 TM

Gas Monitor enclosure cover.

To enable correct connection of all plugs note there location before

removing them.

(2) Pull the terminal plugs to release them from the now accessible printed

board.

(3) Feed the cable (not included) into the enclosure and connect it to the

appropriate terminal plugs.

(4) Make sure that each cable conductor is connected correctly to ensure proper

functioning of the control unit.

(5) If installing a RESET push-button:

Feed a 2-core cable to the J10 terminal plug (Æ Fig. 3).

To avoid electrical interference due to relay cables, this cable

must only be supplied with DC power.

Connect the 2-core cable to the two connections of the J10 terminal plug.

Identify the cable to allow proper connection at the push-button

Route the cable to the push-button switch and connect the cable to it.

Loading...

Loading...