Configuring the job computer

Configuring the nozzles - for field sprayers with pressure sensor regulation

1. - Press for the icon to appear in the “User data” area.

2. Enter the intended application rate in the field.

3. Enter the pressure range for the nozzle colour.

4. In the “Results” area, you can see the speed at which the application rate can be achieved.

Calibrate the nozzles

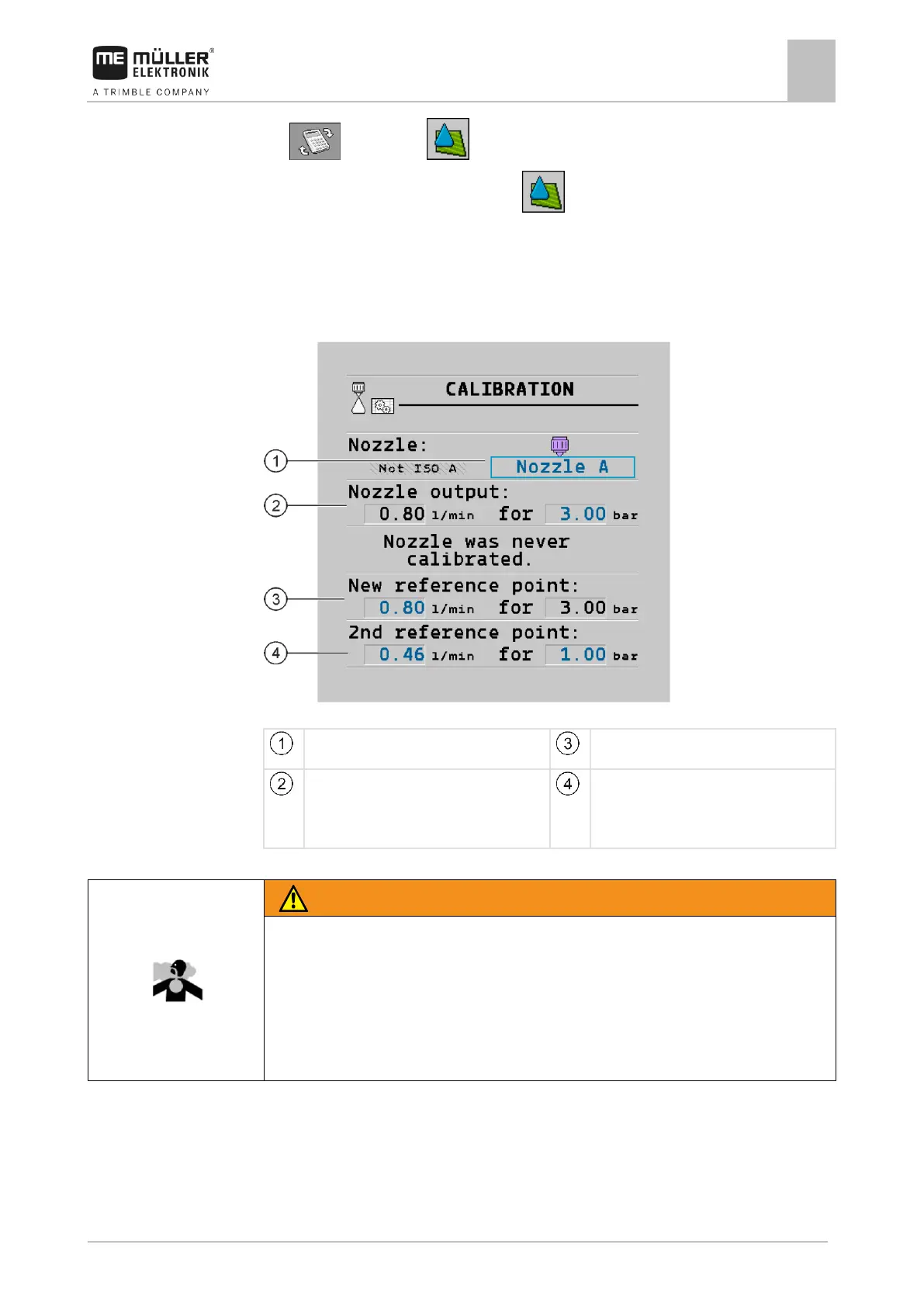

“Calibration” screen

Nozzle output at 3 bar - Result of the

calibration

Current nozzle output. When you change the

pressure, the newly calculated nozzle output

appears.

For non-standard nozzles, the calibration must

be repeated at a different pressure. This

pressure should be about as high as the

intended working pressure.

Spray liquid or spray liquid residues

Danger of poisoning or chemical burning

◦ Clean the spray liquid tank thoroughly prior to calibration. The field sprayer must be free of

spray liquids or spray liquid residues.

◦ Use only clear water during calibration.

◦ Wear required protective equipment.

Calibrate a standard nozzle as follows:

The tank is filled with clear water.

There are no spray liquid residues in the tank or the pipelines.

Loading...

Loading...