Manual# I27028 3-2 Rev. 2 – 11/22/2017

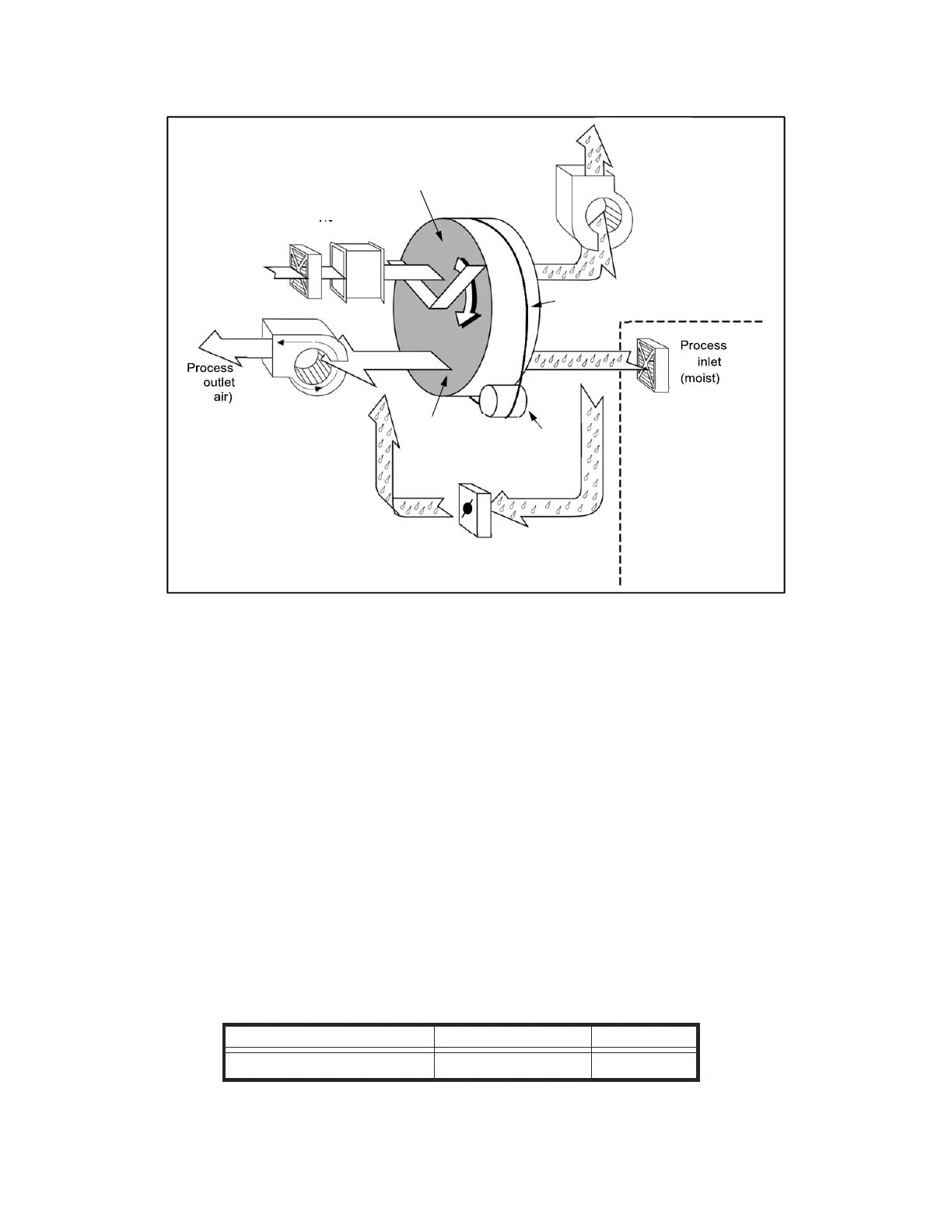

Figure 3-2

COMPLETE OPERATING UNIT

Figure 3-1 and Figure 3-2 show that, at one moment, the wheel is being used to pick up

moisture, and a moment later, the wheel is being heated to drive off the moisture. In

the R-Series unit, both actions are happening at the same time, on different sections of

the wheel. All sections of the wheel go through the following cyclic process:

• At the beginning of the process, this section of the wheel is exposed to the damp

“process” air.

• As the wheel turns, this section of the wheel moves under the stream of heated

“reactivation” air. This part of the wheel is then dried out by the heated air.

• Finally, the dried part of the wheel turns into the “process” area again so it can pick

up more moisture.

During this cycle, the wheel does not stop. One side of the wheel is picking up moisture

while the other side is being dried out. The wheel rotates quite slowly – 8 revolutions

per hour.

The HoneyCombe

®

wheel has been carefully designed. The honeycomb material is non-

metallic and does not react to bacteria. The desiccant material used in this model is

shown in the following table:

Desiccant Type

Color

Marking

Titanium enhanced silica gel Red Tigel

A wheel using titanium enhanced silica gel depends on the “adsorption” principle. Each

particle of chemical can bond with a large number of water molecules. Each water molecule is

attracted to many sites on the outside of the silica gel molecule. The process can be reversed

within the wheel by adding heat. As the desiccant is heated, it releases water to the air.

air

(dry

Process

sector of

wheel

air

Bypass damper

R15 onl

Reactivation

sector of wheel

Drive

Moto

Additional

filte

Reactivation

Blowe

Reactivation

air outlet

(moist)

Reactivation

Heate

Filter

Reactivation

air inlet

outside air

Blower

Desiccant

wheel

Loading...

Loading...