Manual# I27028 6-15 Rev. 2 – 11/22/2017

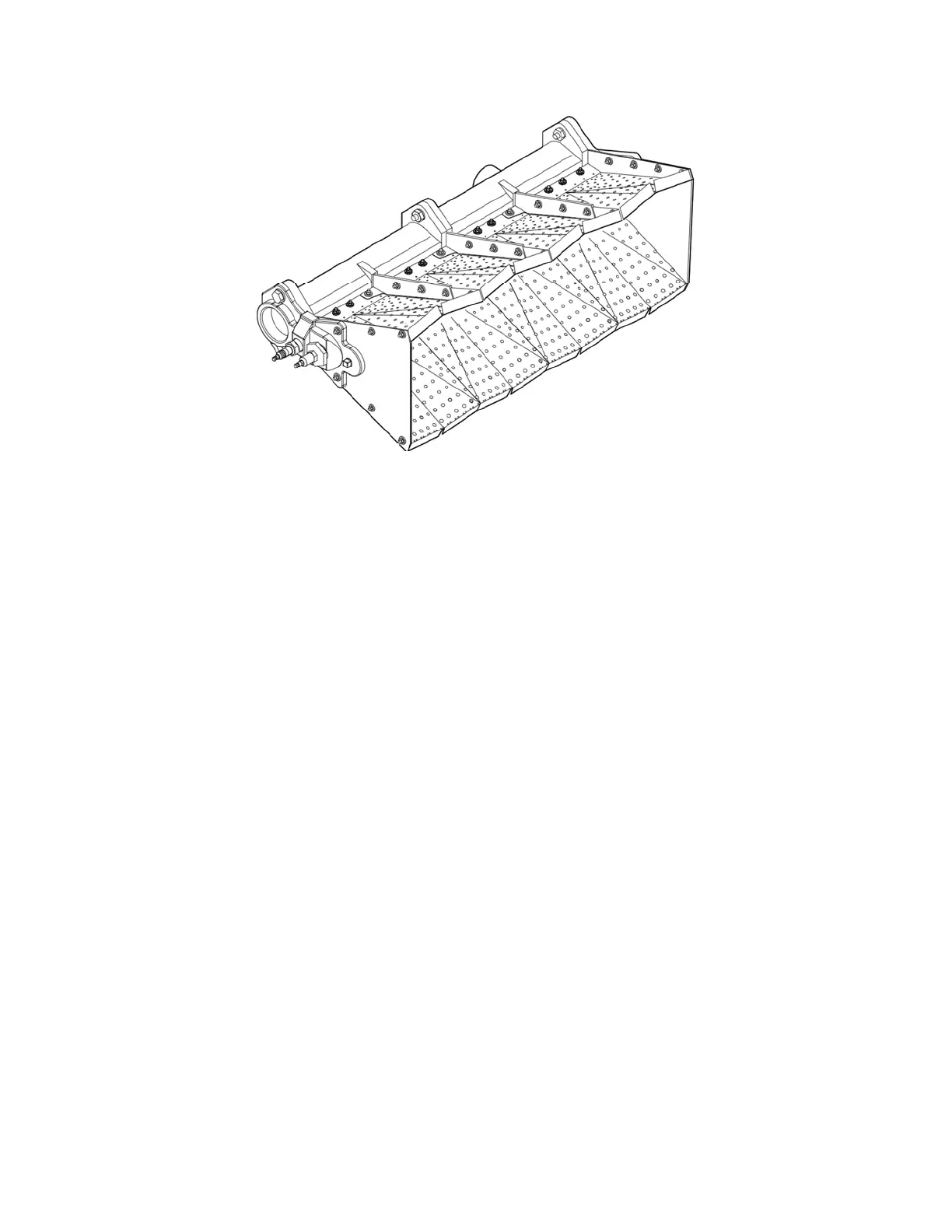

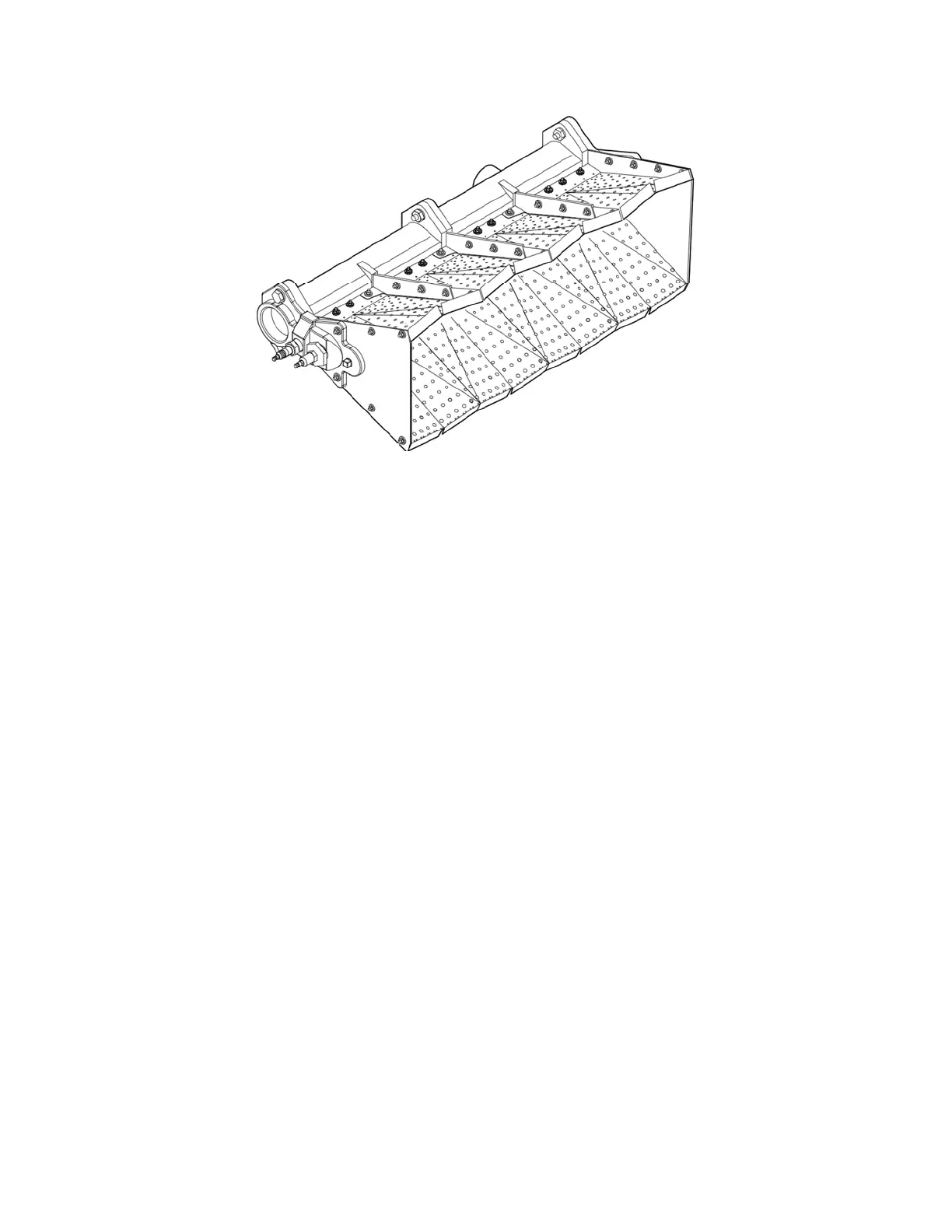

Figure 6-5

AIR WINGS

6. Allow the burner to fire and ensure that the 'heated to' value entering the desiccant

wheel does not exceed 300°F.

7. Confirm that when the burner is firing, the supply gas pressure up to the Munters

supplied equipment is between the minimum and maximum gas supply pressure

values listed on the rating plate.

• If the gas pressure is not correct, make adjustments to the supply gas pressure until

it is within the two values. The equipment must not be operated above or below the

gas supply pressure values listed on the rating plate.

• The supply gas pressure regulator supplying fuel to the Munters equipment must be

of the "lock-up" type to prevent excessively high pressure from reaching the Munters

equipment when the burner is not firing.

8. Ensure that the profile plates are adjusted to produce a 0.8" WC drop across the

plates while the burner is firing. Make sure the reactivation flow air pressure drop is

set properly before checking the profile plate pressure drop. Do not adjust the

plates while the burner is firing.

9. Use a pressure measuring device capable of measuring pressures up to 13" WC

and rated for use with combustible gasses. Attach this between port C and port B

shown in Figure 6-6. Port C should be connected to the burner manifold and port B

should be downstream of the profile plate.

Loading...

Loading...