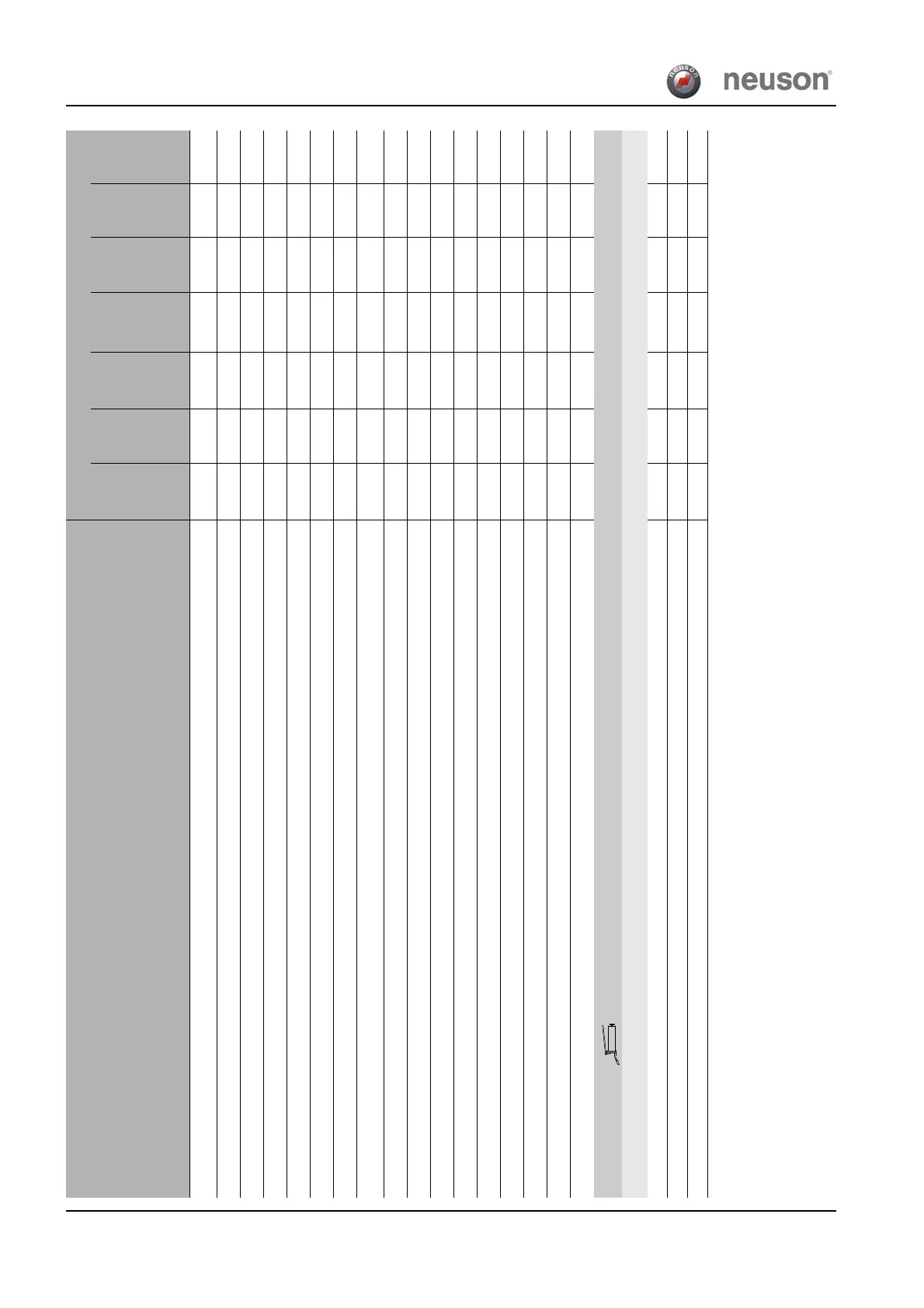

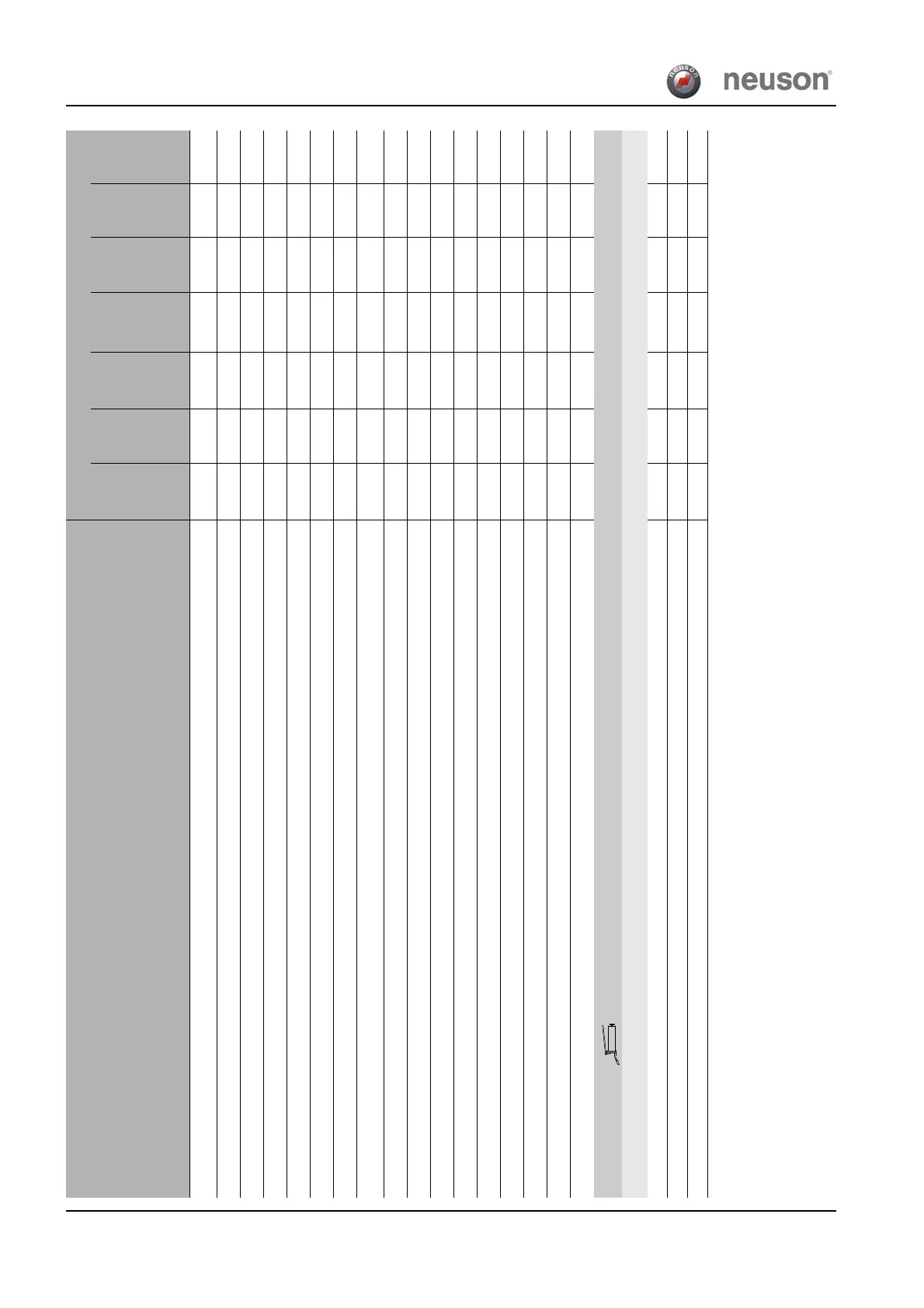

5-32 BA 3001 En – Edition 2.0 * * 345001b540.fm

Maintenance

Check injection nozzles and valves

6

●

Empty diesel fuel tank

●

Check battery electrolyte. Fill up with distilled water if necessary

●● ●

Tyre check (damage, air pressure, tread depth)

●●

Wheel nuts

●●

Check alternator, starter and electric connections, bearing play and function

●

Preheating system, electric connections

●

Pressure check of primary pressure limiting valves

7

●●

Check piston rods for damage

●●

Check screws for tightness

●●

Pin lock

●●

Line fixtures

●●

Check telltales for correct function

●●

Insulating mats in engine compartment

●●

Cleanliness of access

●●

Adhesive labels and Operator's Manual

●●

Engine cover gas strut

●●

Lubrication service ( ):

Lubricate the following assemblies/components:– see Lubrication plan on page 5-33

• Steering ram ●●

• Tilt ram – offset ram ●●

• Articulated joint ●●

1. Drain engine oil the first time after 50 s/h, then every 250 s/h

2. Replace the engine oil filter the first time after 50 s/h, then every 250 s/h

3. Replace the fuel filter the first time after 50 s/h, then every 250 s/h

4. Replace the hydraulic oil filter insert the first time after 50 s/h, then every 500 s/h

5. Clean the water ducts every other 1000 s/h servicing

6. Check the injection nozzles and the valves every other 1500 s/h servicing

7. Check the first time at 50 s/h, then every 500 s/h

5.13 Maintenance plan (overview)

Work description

For service and maintenance work on the attachment, please refer to the operation and maintenance manual of the

attachment manufacturer as well.

Maintenance plan/service hours (s/h)

Maintenance

work

( once a day)

Every 50 s/h

Every 250 s/h

Every 500 s/h

Once a year or

after 1000 s/h

After 1500 s/h

Customer

Loading...

Loading...