When dimensioning the collector, consideration must

be given to the geographical location, type of rock and

ground and the degree of coverage provided by the

heat pump.

When installing the collector hose ensure it rises con-

stantly towards the heat pump to avoid air pockets. If

this is not possible, install high points to vent the air.

All brine pipes in heated rooms must be insulated

against condensation. The level vessel (NK) must be

installed as the highest point in the collector system and

on the incoming pipe before the brine pump. Note that

condensation may drip from the level vessel. Position

the vessel so that this does not harm other equipment.

As the temperature of the collector system can fall

below 0 °C it must be protected against freezing down

to -15 °C. One litre of ready mixed brine per meter of

collector hose (applies when using PEM-hose 40 x 2.4

PN 6.3) is used as a guide value when making the vol-

ume calculation.

The level vessel must be marked to show the type of

antifreeze used.

Shut-off valves should be installed as close to the heat

pump as possible. Fit a particle filter to the incoming pipe.

In the case of connection to an open groundwater sys-

tem, an intermediate frost-protected circuit must be

provided, because of the risk of dirt and freezing in the

evaporator. This requires an extra heat exchanger.

Pipe connections 11

FIGHTER 1140

Pipe installation must be carried out in accordance

with current norms and directives. FIGHTER 1140 can

operate up to a return temperature of about 58* °C

and an outgoing temperature from the heat pump of

about 70* °C. The compressor produces up to 65* °C,

the rest is obtained using additional heating.

* Applies to 5 kW 1-phase and 6 - 17 kW 3-phase 3 x 400 V.

The other heat pumps has a max return temperature

of approximately 50 °C and an outgoing max tempera-

ture from the heat pump of approximately 60 °C.

Since FIGHTER 1140 is not fitted with shut-off valves,

these must be fitted outside of the heat pump to facili-

tate servicing.

General

Pipe connections (collector)

The heating medium pump (VBP) runs at the same

time as the brine pump (KBP) with fixed condensing

(docking option 4) in auto mode.

Heating medium pump

NOTE!

The pipe system needs to be flushed

out before the heat pump is connected

so that debris cannot damage

component parts.

Pipe connections for the heat medium side are made

at the top. All required safety devices, shut-off valves

(as close to the heat pump as possible), and particle

filter (supplied) are fitted.

You should fit either an overflow valve or remove

some of the thermostats when connecting to systems

with thermostats on all the radiators (coils).

Pipe connections

(heating medium)

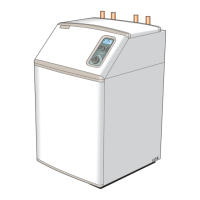

The equipment can be supplemented with a fan coil

unit to make the connection of free cooling possible.To

avoid condensation, all pipes and other cold surfaces

must be isolated with diffusion-proof material.Where

the cooling demand is high, fan convectors with drip

trays and drain connection are needed. The collector

circuit should be fitted with a pressure expansion ves-

sel

. If there is a level vessel, this should be replaced.

Free cooling

Brine in

Brine out

Brine in

Brine out

Fan convectors

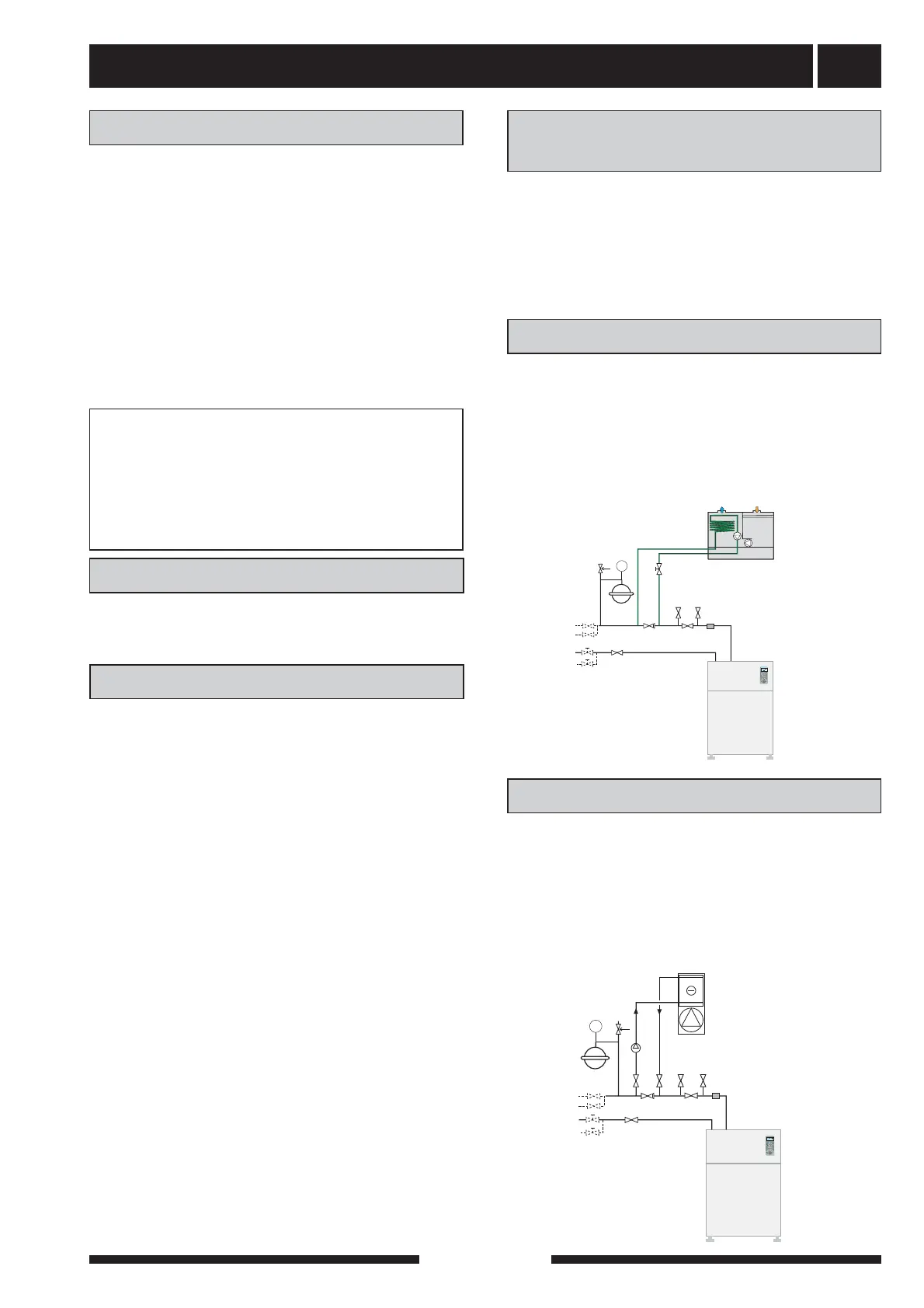

The installation can be supplemented with the exhaust

air module FLM to provide ventilation recovery. To

avoid condensation, all pipes and other cold surfaces

must be isolated with diffusion-proof material. The col-

lector circuit should be fitted with a pressure expan-

sion vessel

. If there is a level vessel, this should be

replaced.

Ventilation recovery

Extract air

Ø 160

Exhaust air

Ø 160

Loading...

Loading...