Revision 2

4.

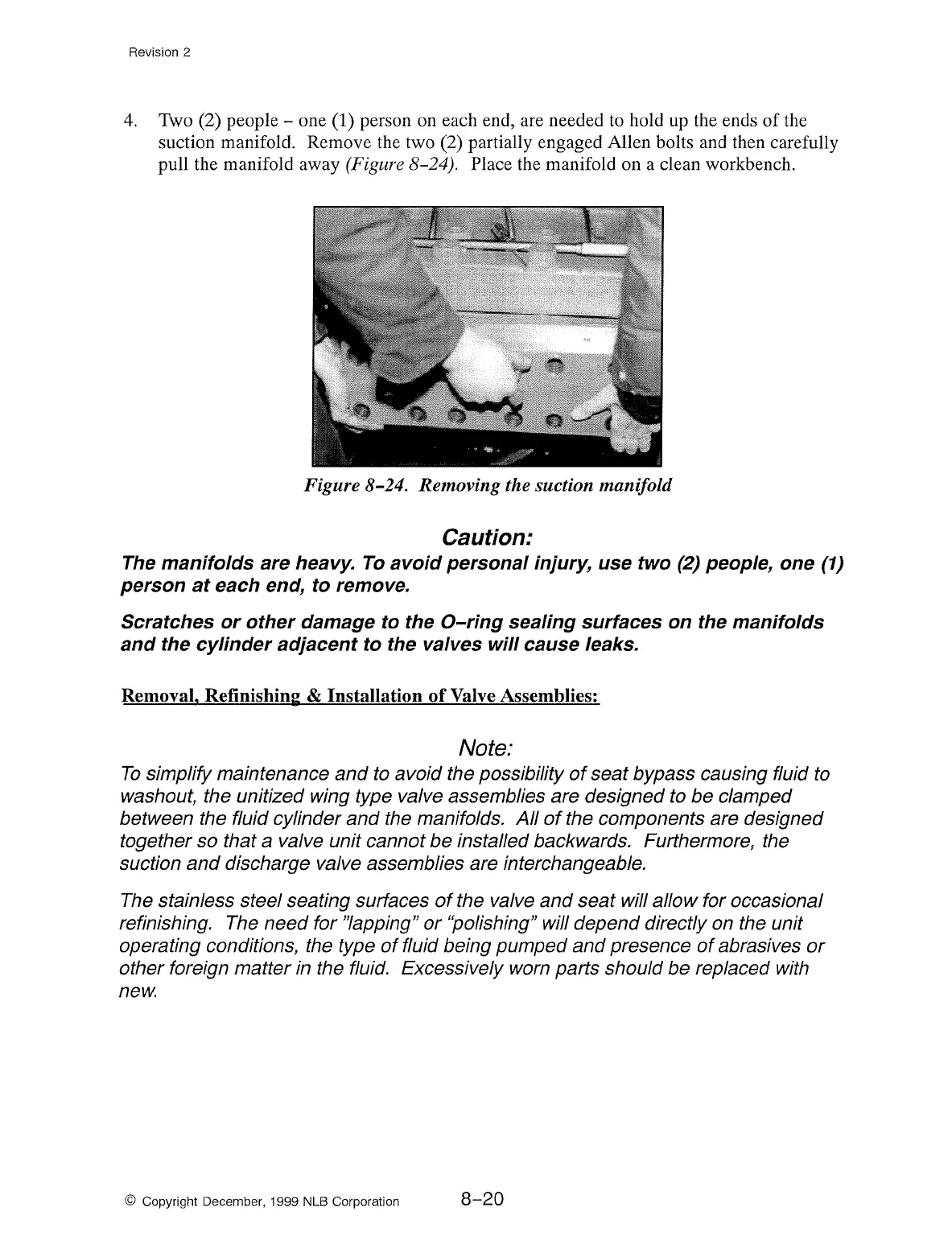

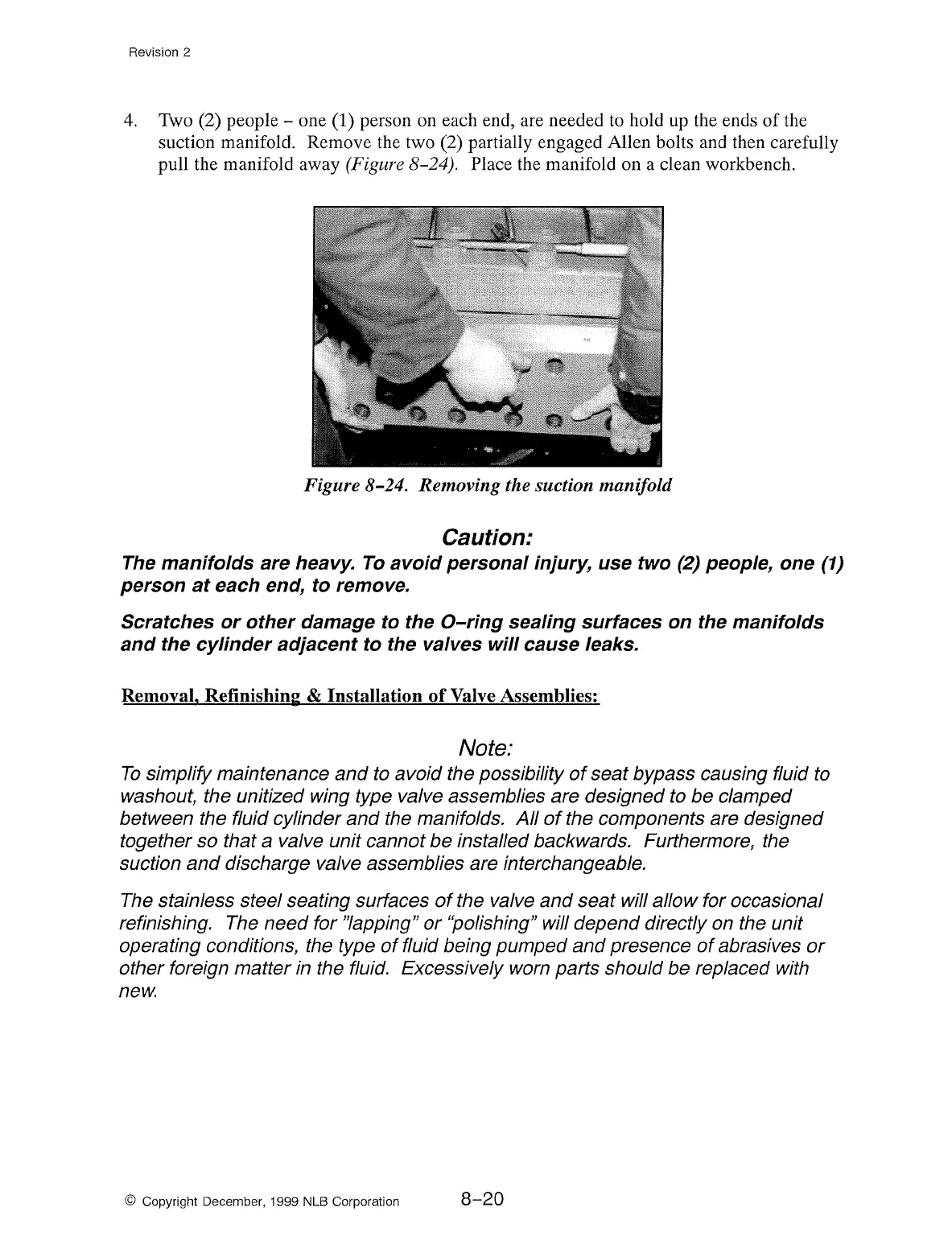

Two (2) people - one (1) person on each end, are needed to hold up the ends

of

the

suction manifold. Remove the two (2) partially engaged Allen bolts and then carefully

pull the manifold away

(Figure 8-24). Place the manifold on a clean workbench.

Figure 8-24. Removing the suction manifold

Caution:

The

manifolds are heavy.

To

avoid personal injury, use two

(2)

people, one

(1)

person

at

each end,

to

remove.

Scratches

or

other damage

to

the

0-ring

sealing surfaces on the manifolds

and the cylinder adjacent

to

the valves will cause leaks.

Removal, Refinishing & Installation

of

Valve Assemblies:

Note:

To

simplify maintenance and to avoid the possibility

of

seat bypass causing fluid to

washout, the unitized wing type valve assemblies are designed to be clamped

between the fluid cylinder

and

the manifolds.

All

of

the components are designed

together so that a valve unit cannot

be

installed backwards. Furthermore, the

suction

and

discharge valve assemblies are interchangeable.

The

stainless steel seating surfaces

of

the valve and seat will allow for occasional

refinishing. The need for

"lapping"

or

"polishing" will depend directly on the unit

operating conditions, the type

of

fluid being pumped and presence

of

abrasives

or

other foreign matter in the fluid. Excessively worn parts should be replaced with

new.

© Copyright December, 1999 NLB Corporation

8-20

Loading...

Loading...