Revision 6

10.

If

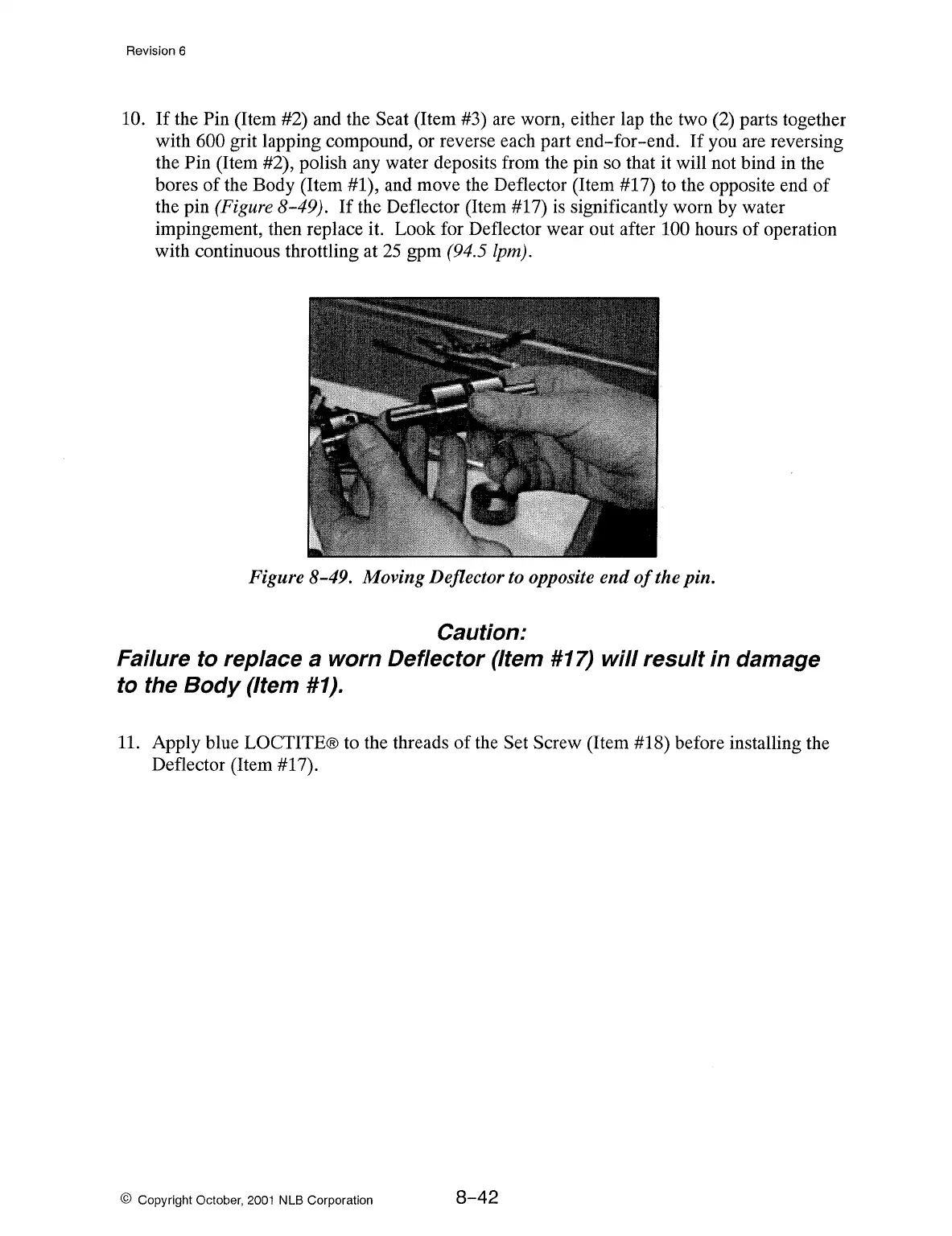

the Pin (Item #2) and the Seat (Item #3) are worn, either lap the two (2) parts together

with

600 grit lapping compound, or reverse each part end-for-end.

If

you are reversing

the Pin (Item #2), polish any water deposits from the pin so that it will not bind in the

bores of the Body (Item #1 ), and move the Deflector (Item #17)

to

the opposite end

of

the pin (Figure 8-49).

If

the Deflector (Item #17) is significantly worn by water

impingement, then replace it. Look for Deflector wear out after

100 hours of operation

with continuous throttling at

25

gpm (94.5 lpm).

Figure 8-49. Moving Deflector to opposite end

of

the pin.

Caution:

Failure

to

replace a worn Deflector (Item #17) will result in damage

to the

Body

(Item #1).

11.

Apply blue LOCTITE® to the threads

of

the Set Screw (Item #18) before installing the

Deflector (Item #17).

© Copyright October,

2001

NLB Corporation

8-42

Loading...

Loading...