3 Assembly instructions, storage, preparation, installation

B 1000 en-4419 33

Pos: 124 /A nleit ung en/G etr ieb e/3. Mo nt age, Lag eru ng, Vor ber eitung , Aufs tell ung /M ontag e/ Mon tag e ei nes Nor mm otor s 01 @ 34\mod_1559720023353_388.docx @ 2538703 @ 2 @ 1

3.11 Fitting a standard motor

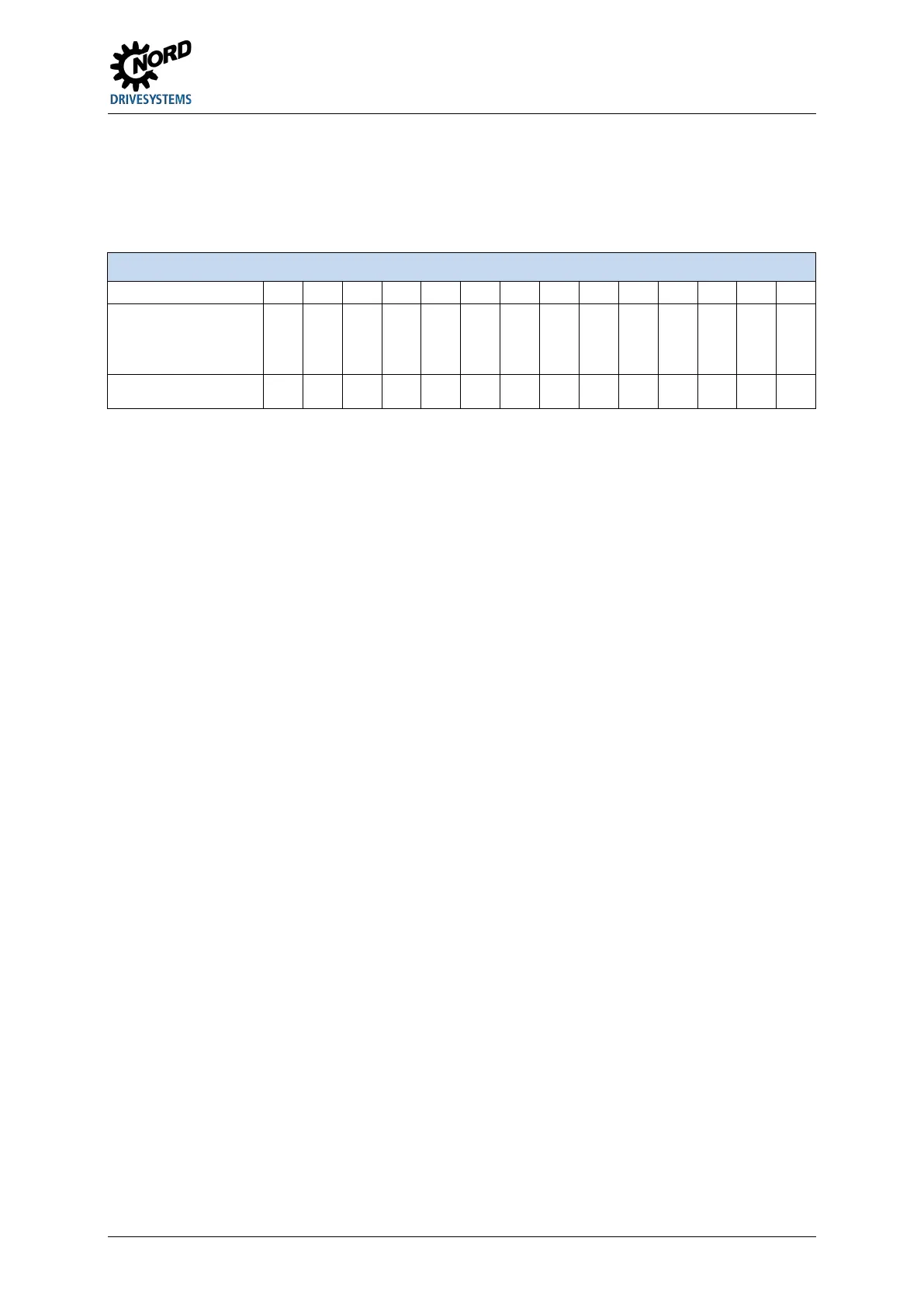

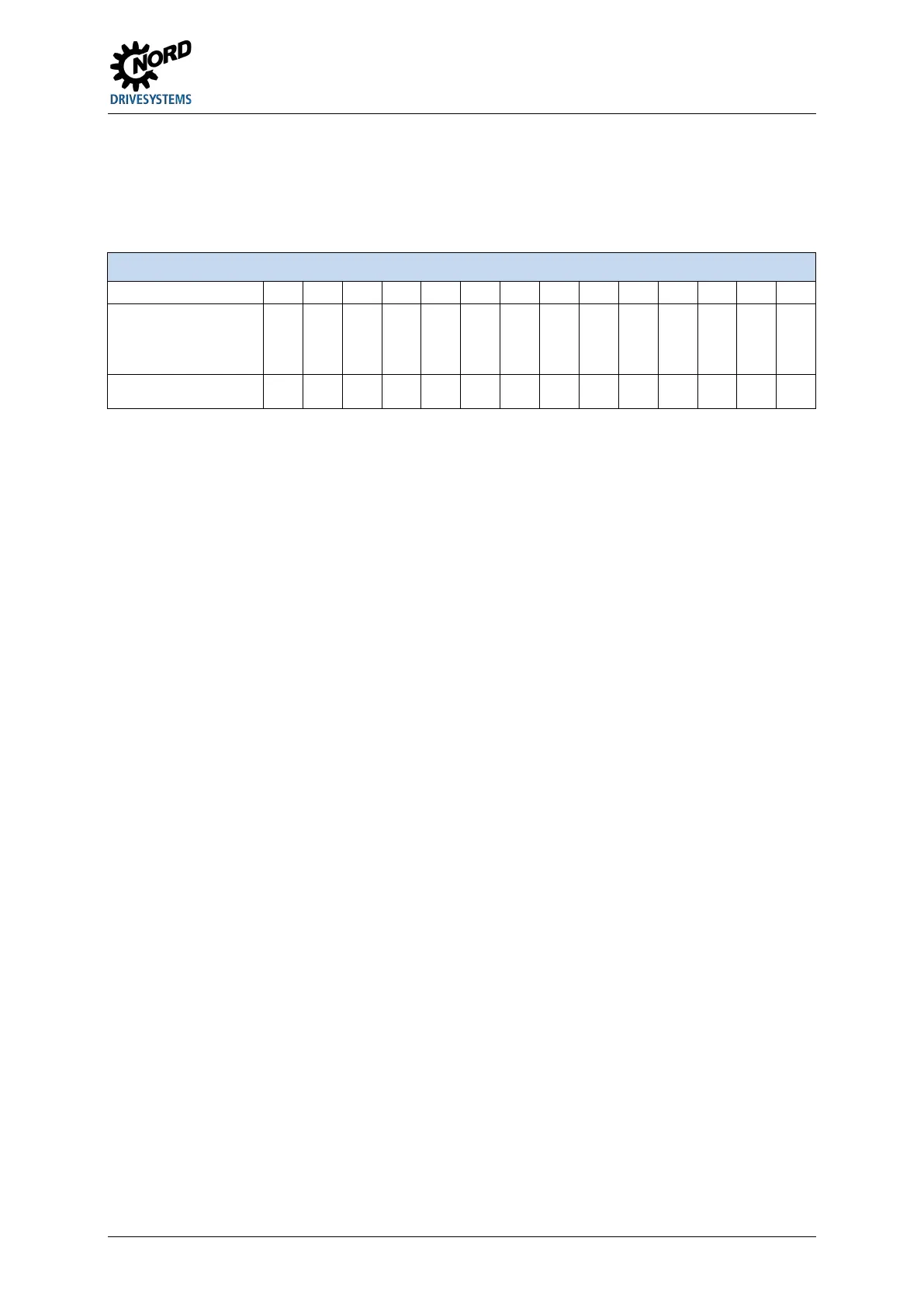

The maximum permitted motor weights indicated in the table below must not be exceeded:

Maximum permitted motor weights

NEMA motor size

56C

Max. motor weight [kg] 25 30 40 50 60 80 100 200 250 350 500 700 1000

1500

Pos: 12 6 /Anlei tung en/G etrieb e/3. Mo ntag e, Lager ung, V orber eitung, Aufs tellung /Mon tage/ Mont age eine s Norm motor s 03 @ 34\mod_1559720057985_388.docx @ 2538779 @ 5 @ 1

Assembly procedure to attach a standard motor to the IEC adapter (Option IEC/NEMA adapter)

1. Clean the motor shaft and flange surfaces of the motor and adapter and check for damage. The

mounting dimensions and tolerances of the motor must conform to DIN EN 50347 / NEMA MG1

Part 4.

2. Push the coupling sleeve onto the motor shaft so that the motor parallel key engages into the

groove in the sleeve on mounting.

3. Tighten the coupling hub on the motor shaft in accordance with the motor manufacturer’s

instructions until it touches the collar. With motor sizes 90, 160, 180 and 225, any spacer bushes

may need to be positioned between the coupling sleeve and the collar. With standard helical gear

units, dimension B between the coupling sleeve and the collar must be observed (see "Figure 19").

Certain NEMA adapters require adjustment of the coupling in accordance with the specifications

indicated on the adhesive plate.

4. If the coupling half contains a threaded pin, the coupling must be secured axially on the shaft. The

threaded pin must be coated with a securing lubricant, e. g. Loctite 242, Loxeal 54-03 prior to use

and tightened to the correct torque (please see chapter 7.4 "Screw tightening torques").

Pos: 12 8 /Anlei tung en/G etrieb e/3. Mo ntag e, Lager ung, Vor ber eitung , Aufs tell ung /M ontag e/ Mon tag e ei nes Nor mm otor s 04 [ni cht -ex] @ 34\mod_1559719975985_388.docx @ 2538665 @ @ 1

5. Sealing of the flange surfaces of the motor and the IEC adapter/ NEMA adapter is recommended if

the motor is installed outdoors or in a humid environment. Before the motor is installed, the flange

surfaces must be completely coated with surface sealant e.g. Loctite 574 or Loxeal 58-14 so that

the flange seals after mounting.

Pos: 12 9 /Anlei tung en/G etrieb e/3. Mo ntag e, L ager ung , V orb ereit ung, A ufs tell ung/M on tag e/M ont age eine s N orm mot ors 05 @ 34\ mod_1559720083583_388.docx @ 2538817 @ @ 1

6. Mount the motor on the adapter. Do not forget to fit the ring gear or the gear sleeve (see Figure

unterhalb).

7. Tighten the adapter bolts to the correct torque (please see chapter 7.4 "Screw tightening torques").

Loading...

Loading...