5 Service and maintenance

B 1000 en-4419 41

5 Service and maintenance

Pos: 24 9 /Anlei tung en/G etrieb e/5. In spekti on un d War tu ng/I nspe kti ons- und W artung sinter vall e/Ins pekti ons- u nd Wart ungsi nter valle [B 1000] @ 39\mod_1572949695416_388.docx @ 2571820 @ 2 @ 1

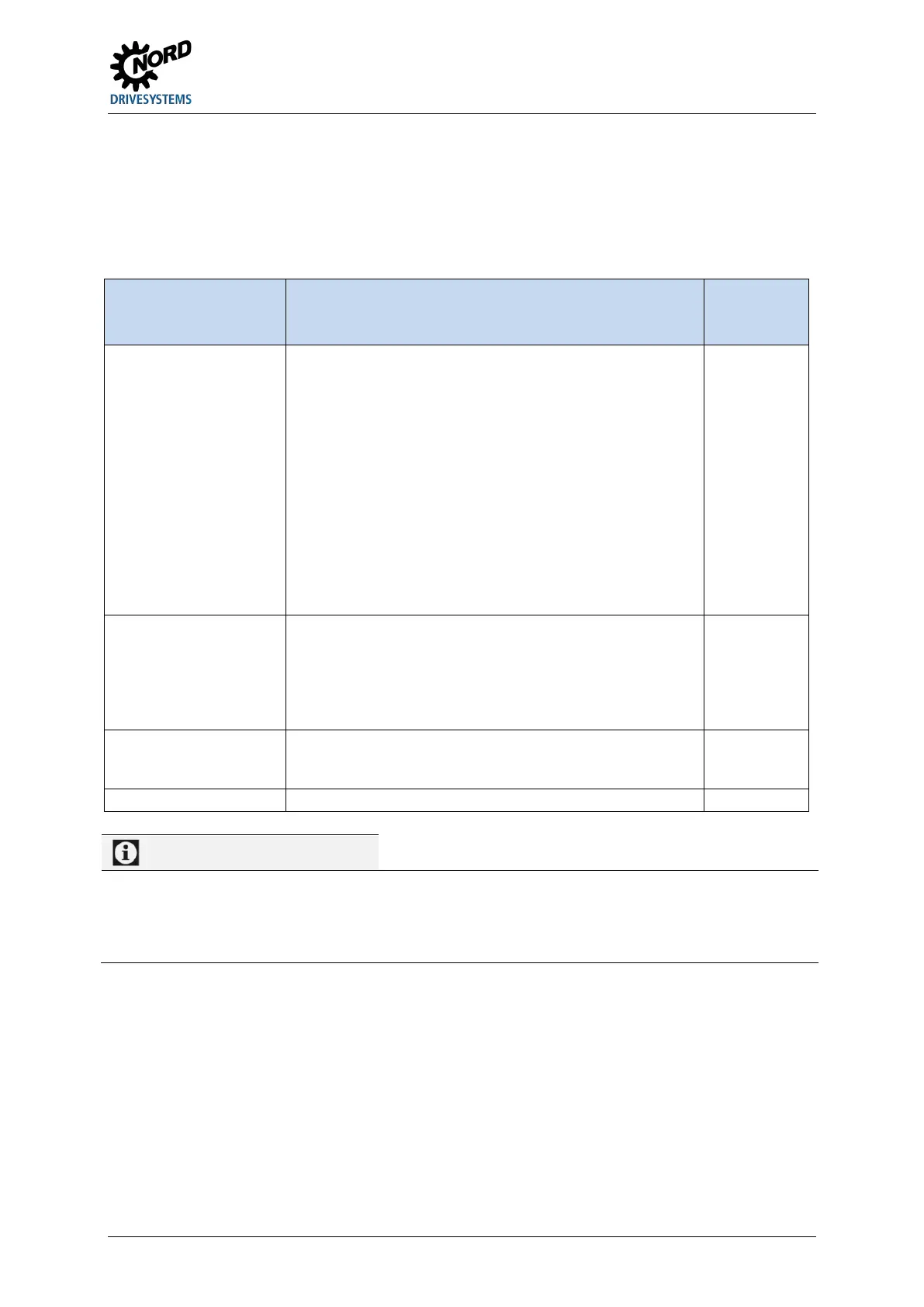

5.1 Service and Maintenance Intervals

Service and Maintenance

Intervals

Service and maintenance work

Information

see Section

At least every six months

• Check running noises

• Check the oil level

• Visual inspection of hose

• Re-grease / remove excess grease

(only applicable for free drive shaft / Option W and for agitator

bearings / Option VL2 / VL3)

• Replace the automatic lubricator /

remove excess grease

(for operating times < 8 h / day): A replacement interval of 1

year is permissible for the lubricant dispenser) (Only for IEC /

NEMA standard motor mounting). Empty or replace the

lubricant collection container with every second replacement

of the lubricant dispenser.

For operating temperatures

up to 80 °C

every 10000 operating

hours,

at least every 2 years

• Change the oil (if filled with synthetic products, the interval is

doubled, with the use of SmartOilChange the interval is

specified by SmartOilChange)

• Clean or replace the vent screw as necessary

• Replace the shaft sealing rings at every oil change

hours,

at least every 4 years

• Re-lubricate the bearings in the gear unit

The oil change intervals apply for normal operating conditions and operating temperatures up to

80 °C. The oil change intervals are reduced in the case of extreme conditions (operating temperatures

higher than 80 °C, high humidity, aggressive environment and frequent fluctuations in the operating

temperature).

Pos: 25 3 /Allg emein/ Allg emeing ültig e Mod ule/---------- Seit enumbr uc h ---------- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

Loading...

Loading...