Gear units – Operating and Assembly Instructions

38 B 1000 en-4419

4 Commissioning

Pos: 185 /A nleit ung en/G etr ieb e/4. In betr ie bna hme/ Ölst and pr üfen [B 100 0] @ 3\mod_1369226311724_388.docx @ 70997 @ 2 @ 1

4.1 Check the oil level

The oil level must be checked prior to commissioning (please see chapter 5.2 "Service and

Maintenance Work").

Pos: 19 1 /Anlei tung en/G etrieb e/4. In betri ebna hme/A ktivier ung de s auto matisc hen Sc hmiers toffg ebers [B100 0] @ 37\mod_1560944532252_388.docx @ 2544743 @ 25 @ 1

4.2 Activating the automatic lubricant dispenser

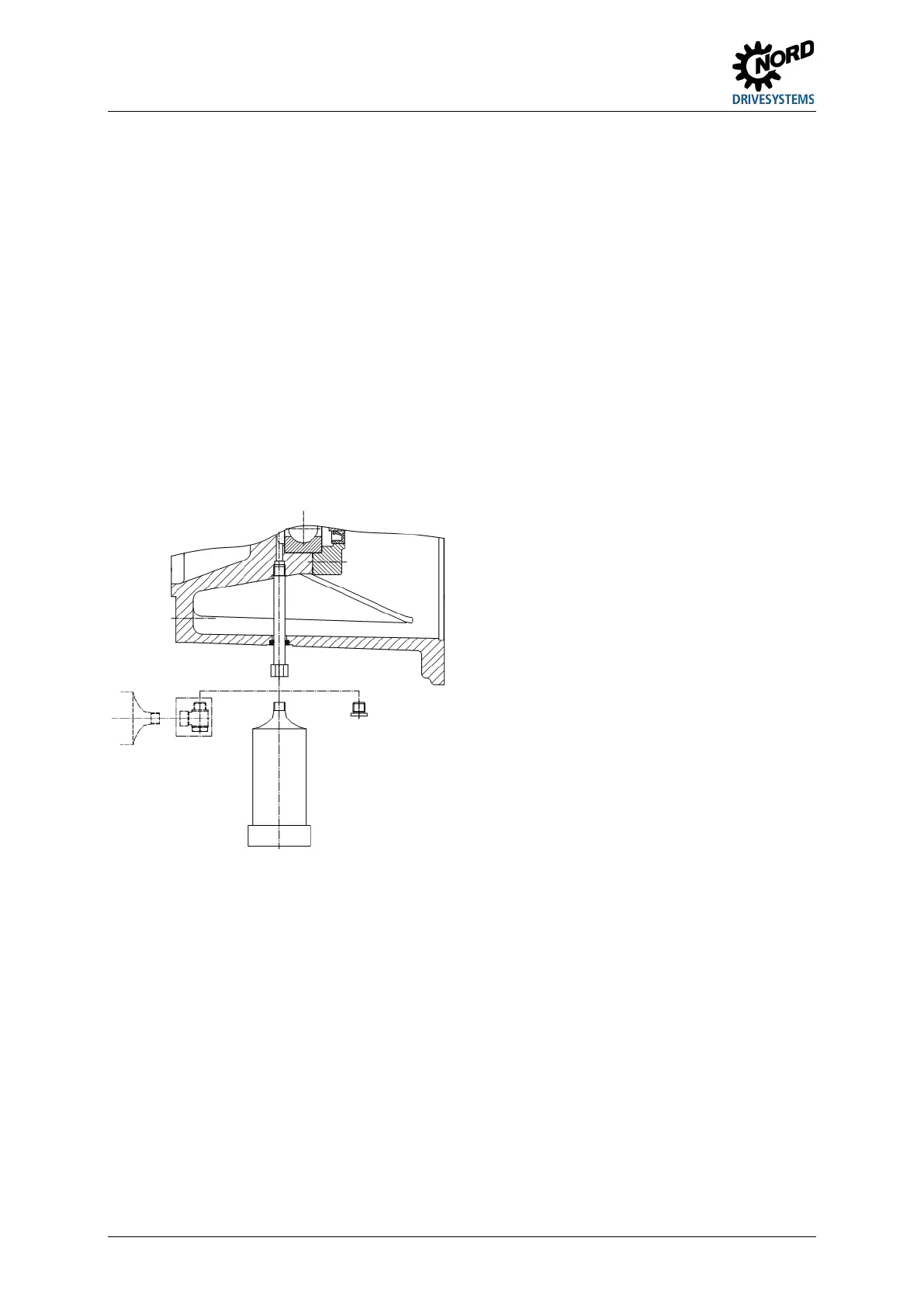

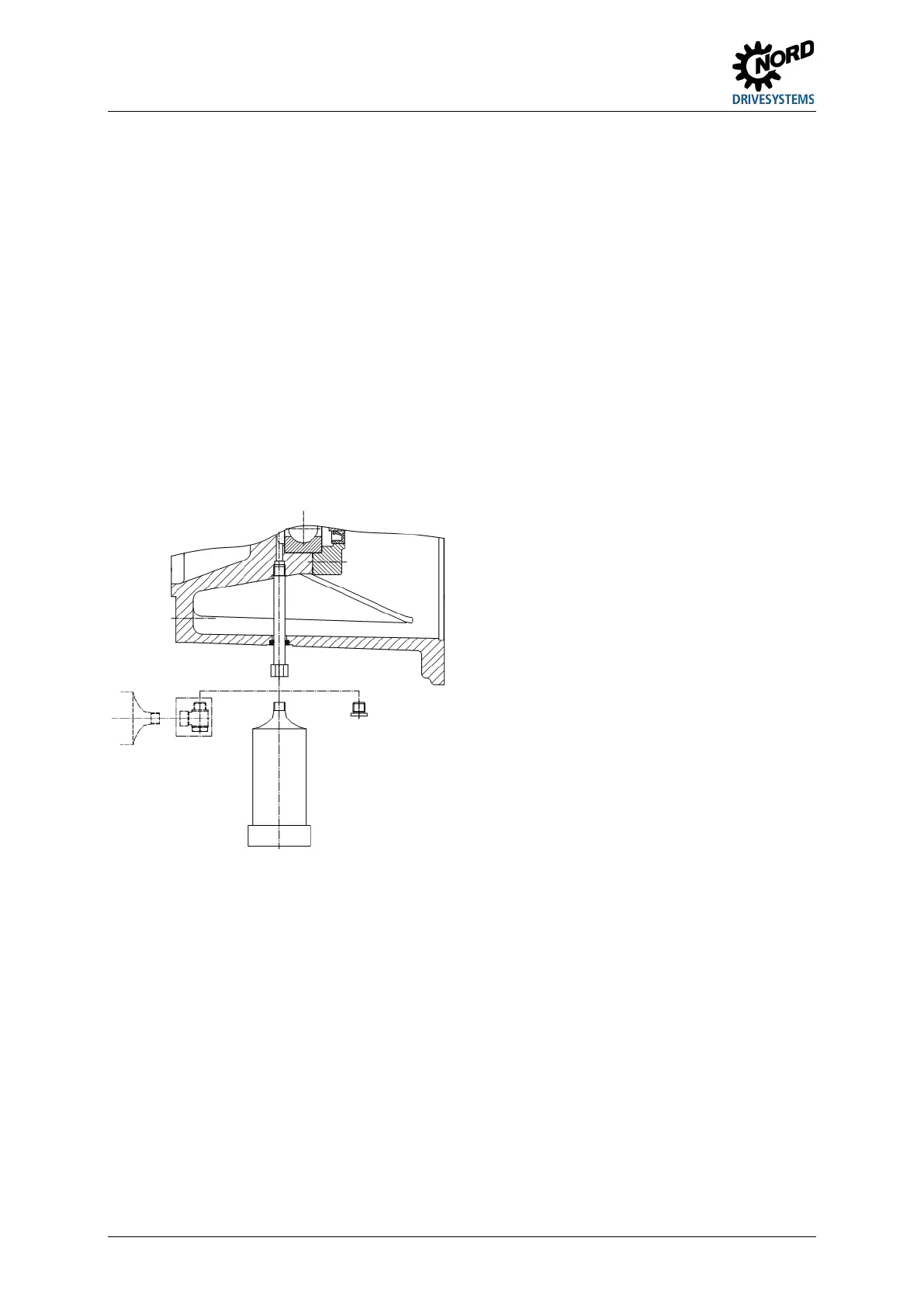

Some gear unit types with standard motor (Option IEC / NEMA) have an automatic lubricant dispenser

for the roller bearings. This must be activated prior to commissioning. The cartridge case cover of the

adapter for attaching an IEC/NEMA standard motor has a red information sign for activation of the

lubricant dispenser. Opposite to the lubricant dispenser there is a grease escape hole which is closed

with a G1/4 cap screw. After activation of the lubricant dispenser, the cap screw can be removed and

replaced with the grease collection container (Part No. 28301210) which is supplied separately with

the delivery.

1. Swivel fitting

2. Grease collection container

3. G1/ 4 cap screw

Figure 23: Fitting the grease collection container

Activating the lubricant dispenser:

1. Loosen and remove the cylindrical screws.

2. Remove the cartridge cover.

3. Screw the activation screw into the lubricant dispenser until the lug breaks off at the defined

fracture point.

4. Re-fit the cartridge cover and fasten it with the cylindrical screw (please see chapter 7.4 "Screw

tightening torques").

5. Mark activation date on the adhesive label indicating the month/year.

Loading...

Loading...