PICO Toµch Controller

44 www.nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

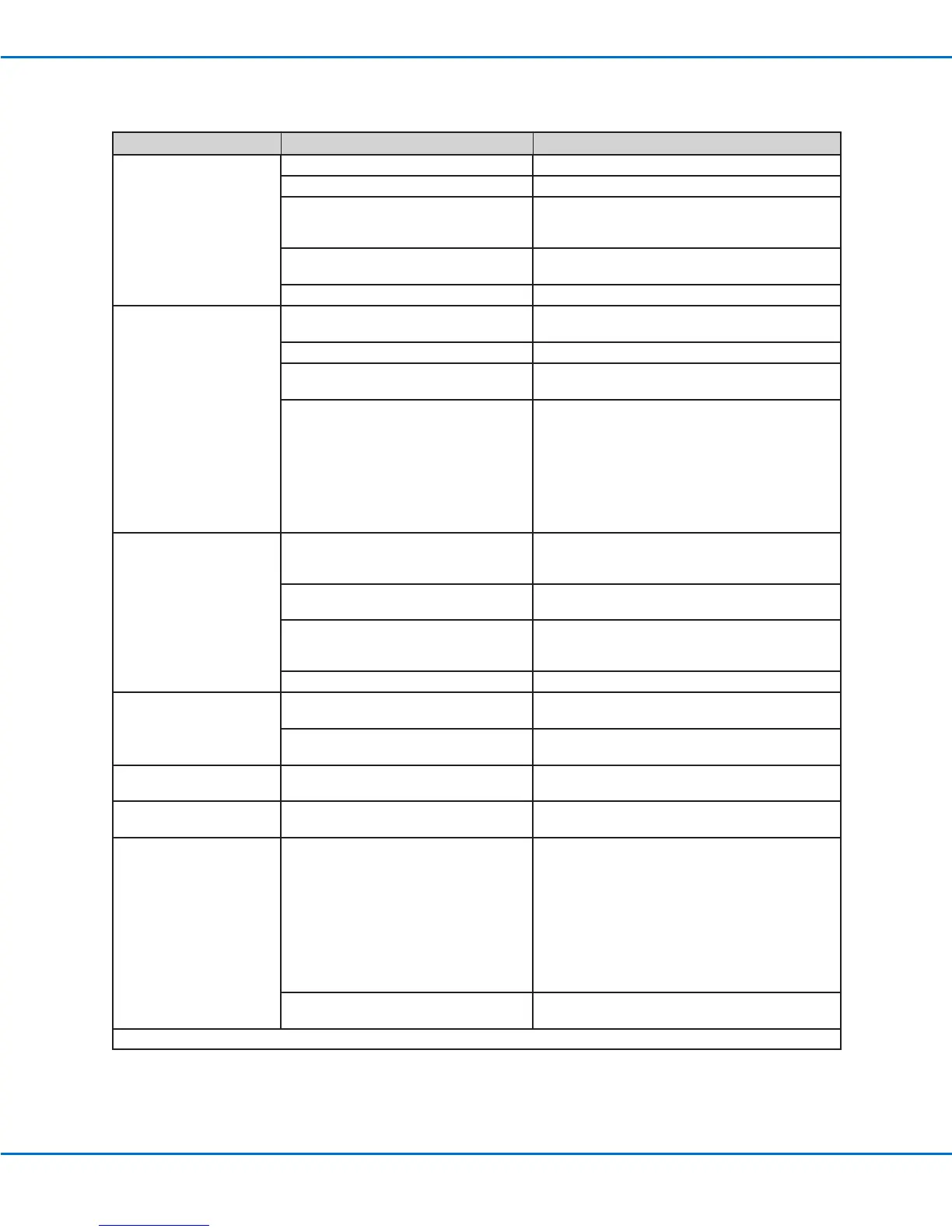

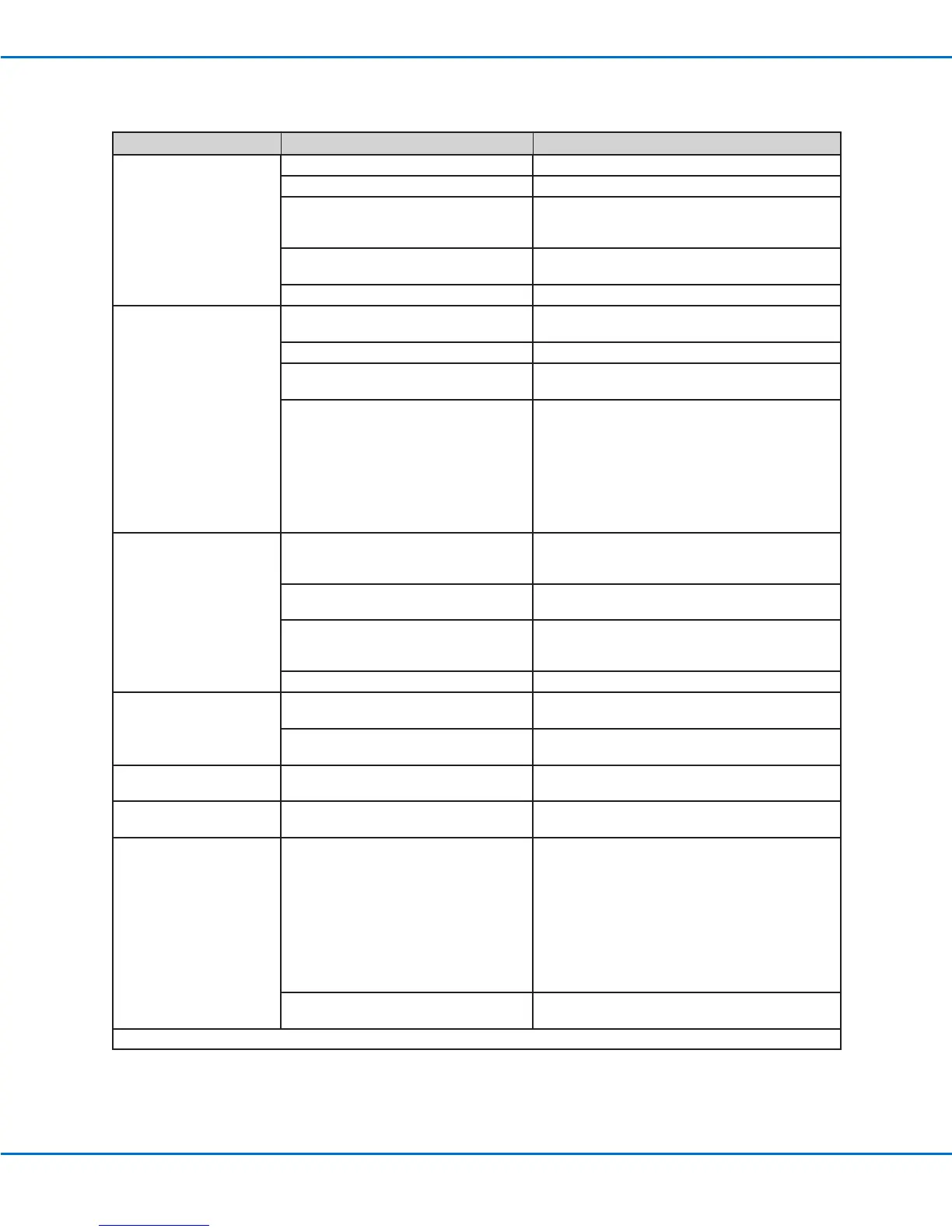

Troubleshooting

Problem Possible Cause Corrective Action

Fluid leaks Valve not powered ON Verify that the valve POWER is ON.

Insufcient closing voltage Increase the closing voltage of the valve.

Improper prole selected If RAMP is not selected for the open and close

WAVE PROFILE settings, verify that the selected

prole is correctly programmed.

Worn or damaged valve Refer to the troubleshooting section of the valve

operating manual.

Damaged driver Contact Nordson EFD.

Valve will not power ON Loose or damaged cable / connection Verify that both valve input cables are connected.

Check the integrity of all cables and connections.

Alarm condition present Correct and clear any pending alarms.

System Alarm: Piezo Driver FAULT Check for a Piezo Driver FAULT alarm. If this

continues to occur, contact Nordson EFD.

Improper prole selected If RAMP is not selected for the open and close

WAVE PROFILE settings, verify that the selected

prole is correctly programmed.

Switch off the controller and wait 5 seconds for the

valve to fully discharge. Disconnect and reconnect

all cables to the controller, then switch on the

controller. If a system restart does not correct the

problem, contact Nordson EFD.

Controller not responding

to an initiate signal

Alarm condition present When an alarm condition is present, the controller

will not initiate. Correct and clear any pending

alarms.

Problem with initiate signal integrity Verify that the signal being user on the USET (Initiate)

circuit is a clean, bounce-free signal (5-24VDC).

Problem with wiring integrity Ensure that the wiring is correctly stripped and that

the conductors are making contact on the 15 pin

connector

Valve not powered ON Verify that the valve POWER is ON.

LCD not responding to

touches

LCD requires calibration Refer to "Calibrating the LCD" on page 38 to

recalibrate the LCD.

System Alarm: LCD Fault Switch off the controller and wait 5 seconds for the

valve to fully discharge, then switch on the controller.

System Alarm: No Valve

Detected

Loose or disconnected valve cable Verify that both valve input cables are connected.

Check the integrity of cables and connections.

System Alarm: Stack Over

Temperature

Piezo stack temperature exceeds

operating limits

Reduce the operating frequency of the valve.

System Alarm: Piezo

Driver FAULT

Piezo driver exceeds operating limits Reduce the operating frequency of the valve.

Switch off the controller and wait 5 seconds for the

valve to fully discharge. Disconnect and reconnect

all cables to the controller, then switch on the

controller. If a system restart does not correct the

problem, contact Nordson EFD.

If RAMP is not selected for the open and close

WAVE PROFILE settings, verify that the selected

prole is correctly programmed.

Clogged lter Clean or replace the lter. Refer to the illustration

provided under "Filter" on page 43.

Continued on next page

Loading...

Loading...