Installation

3-17

Part 1618871−01

2020 Nordson Corporation

ESD Ground Procedures and Equipment

The best protection against ESD is to keep the ground braids as short as

possible and connect them to a central point on the booth base as shown in

the Star diagram. Under normal conditions making Star connections is not

a problem, but in some systems, such as roll-on/roll-off booths, the ground

braids required for a Star connection are too long to be effective against

ESD. In this case, a Daisy Chain ground configuration is acceptable.

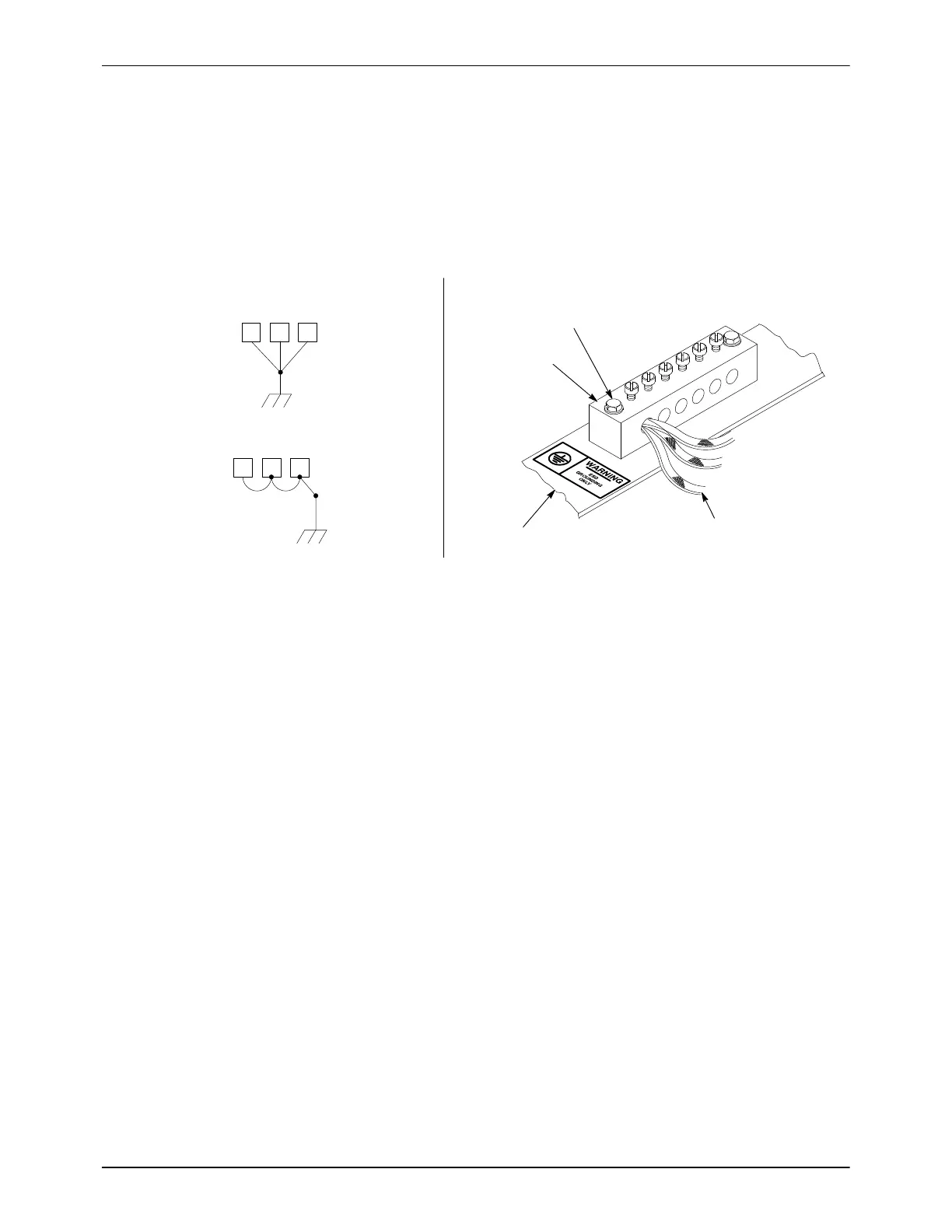

Star Grounding

(Preferred)

Daisy-Chain Grounding

(Alternate)

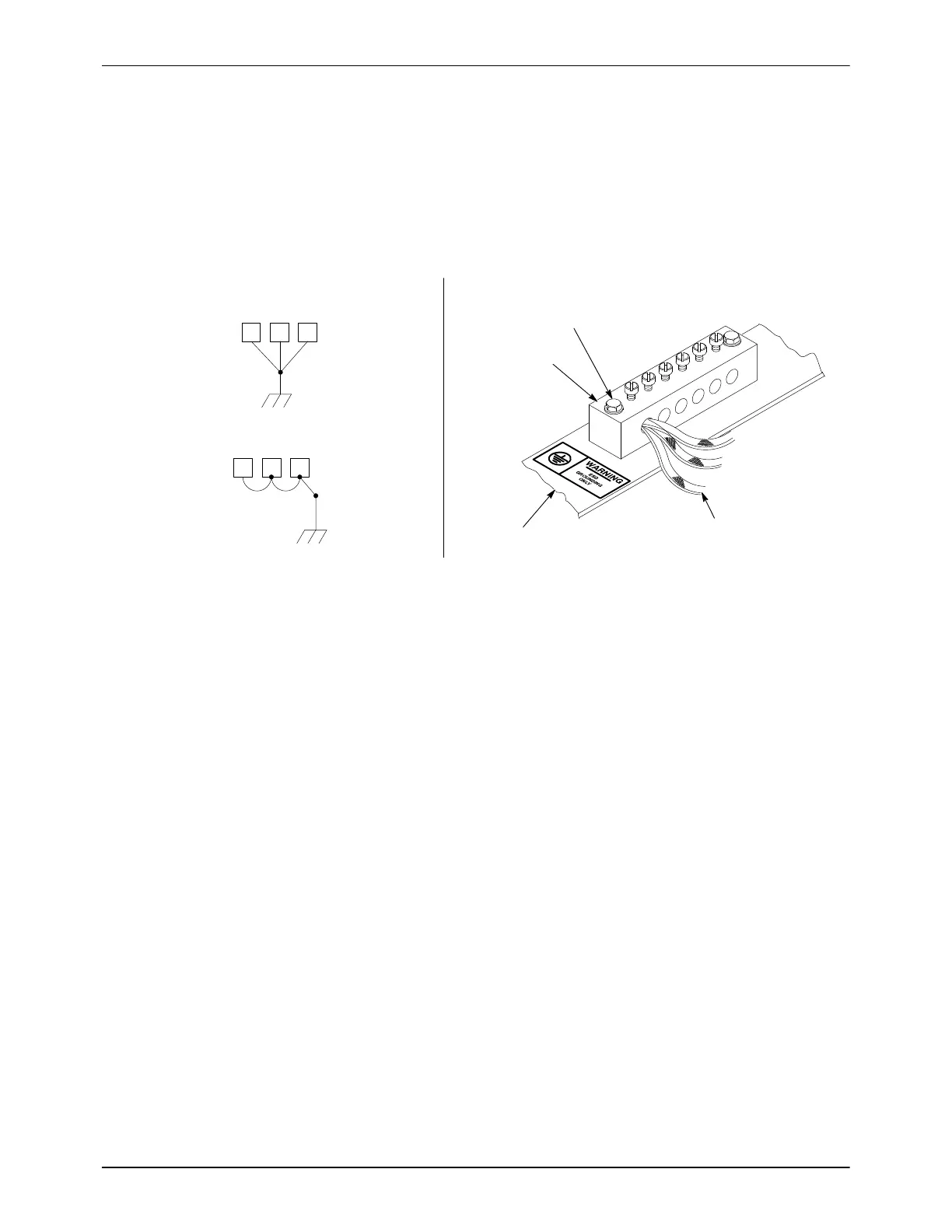

Self-Drilling Screws

Grounding Block

Booth Base

Flat-Braided

Ground Cable

Grounding Block Kit 1067694 Installation

Figure 3-9 ESD Grounding Procedures and Equipment

Always use the special flat-braided copper ESD ground cables furnished

with all Nordson spray gun controllers to ground them. The ESD ground

cables should always be attached to the booth base, not to a panel,

enclosure, or other component bolted to the base. Keep the cables as short

as possible. If using a grounding block kit, make sure the block is installed

directly to the base with the included self-drilling screws.

An ESD grounding block kit is available for connecting the ground braids to

the booth base. The kit contains two 6-position grounding blocks, fasteners,

terminals, and 15 meters (50 feet) of braided ground cable. If additional kits

are required, order:

1067694 Kit, ground bus bar, ESD, 6-position, with hardware

Loading...

Loading...