Fulfill

Retrofit for Mesa Melters

14

Part 1121938_02

2013 Nordson Corporation

Pneumatic & Mechanical Components

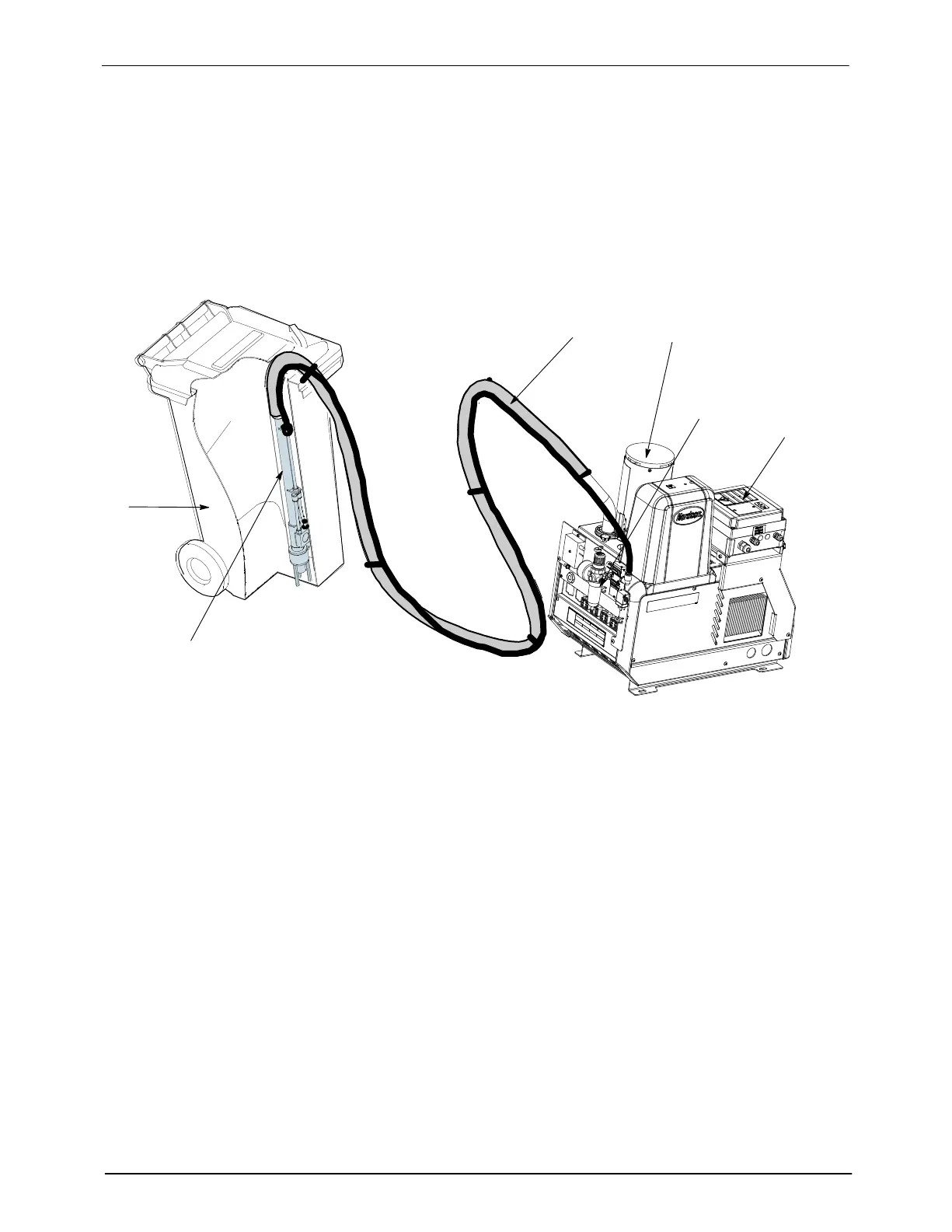

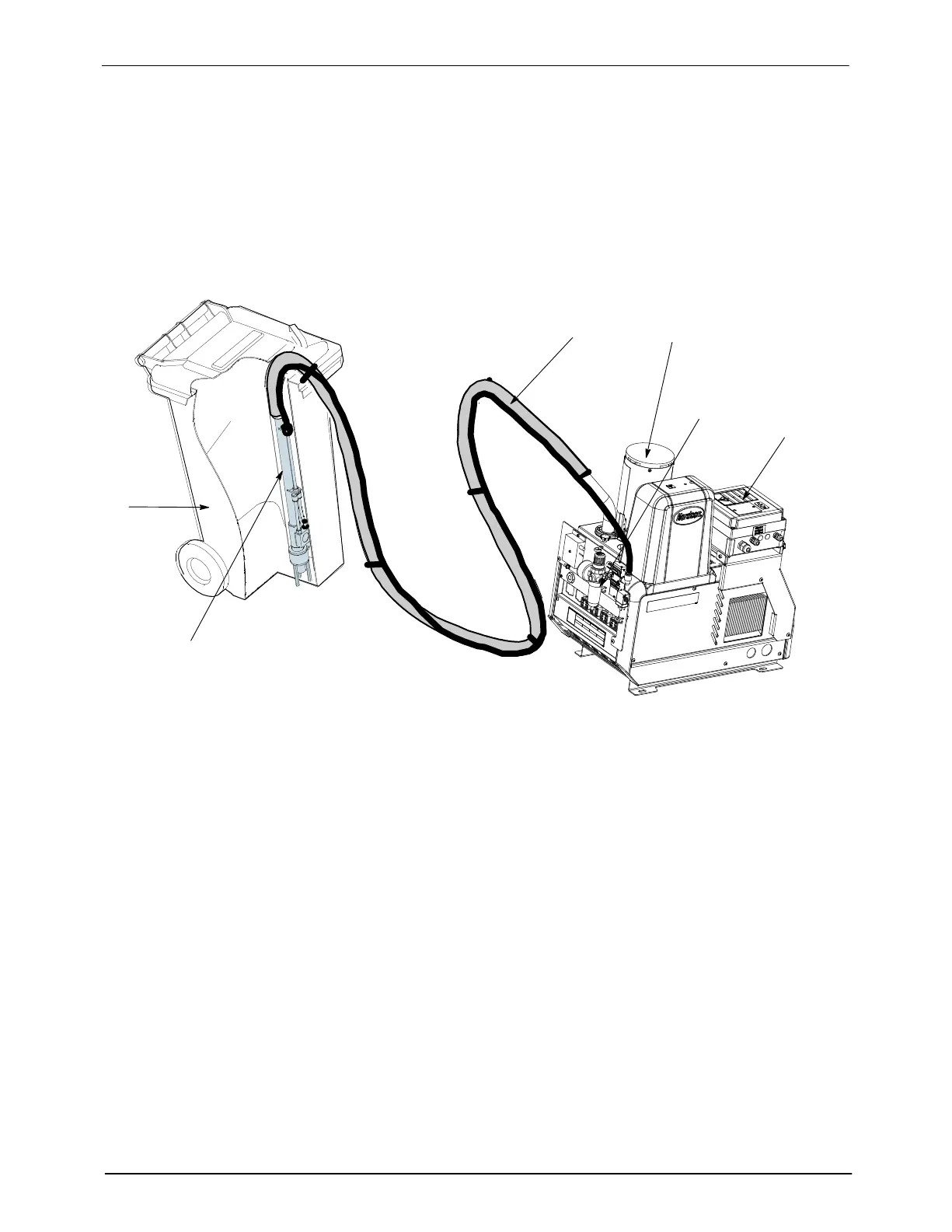

Refer to Figure 3 as you learn about the components of the Mesa Fulfill

retrofit assembly.

1

2

3

4

5

6

Figure 3 Assembled Mesa Fulfill retrofit assembly.

(1). Adhesive Storage Bin

Place adhesive in the adhesive storage bin. The bin contains a gasket that

prevents debris from entering the bin. For best results, break up the

adhesive as much as possible when emptying into the bin. Do not get the

adhesive wet.

(2). Air Pressure Regulator/Solenoid Assembly

The supplied air pressure regulator is permanently set at 65 psig, the optimal

setting for most adhesives.

The solenoid valve turns on after the sensor indicates level state and the time

delay has been reached. The solenoid directs compressed air to flow to the

suction lance.

Loading...

Loading...