Fulfill

Retrofit for Mesa Melters

30

Part 1121938_02

2013 Nordson Corporation

Troubleshooting

NOTE: Refer to Appendix A, Retrofit Refill System With Nordson Level Sensor, for updated

information.

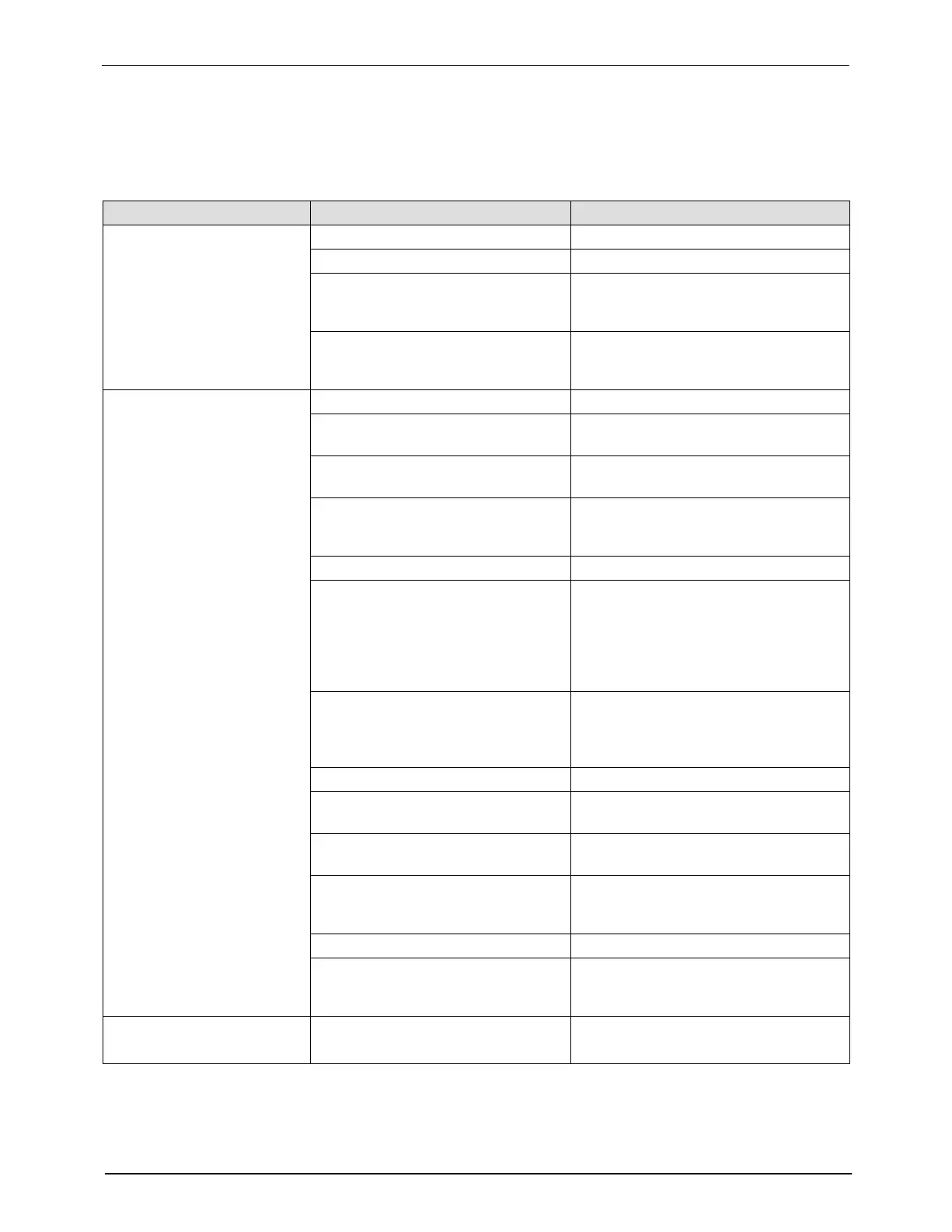

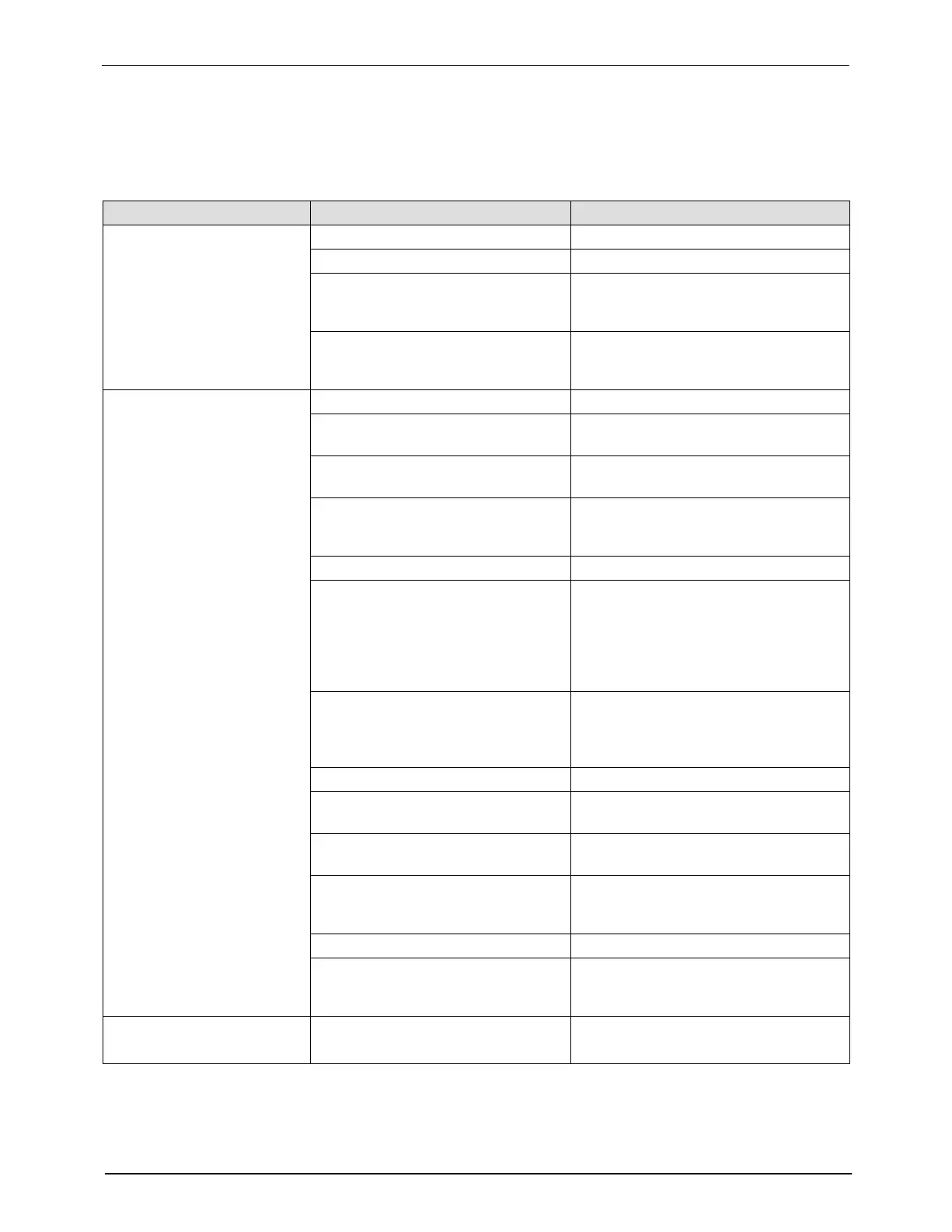

Problem Possible Cause Corrective Action

1. System overfilled

Solenoid stuck open Clean or replace.

Sensor ground wire not connected Connect.

Refill board not working Replace if defective. See Refill PCA

Troubleshooting Instructions shown

later in the Troubleshooting section.

Sensor not calibrated properly Calibrate the sensor. Refer to Level

Sensor Adjustment and Calibration

provided earlier.

2. System underfilled

No adhesive Add adhesive.

No power Ensure that power is available to the

system.

Adhesive bridging Dislodge adhesive. Add optional

vibrator kit if problem persists.

Clogged wand/hose/lid Inspect the parts for improper

connections, clogs or kinks. Replace

as needed.

Clogged filter sock Replace if needed.

No/low air pressure Verify that sufficient air pressure and

flowrate is supplied to the Fulfill unit

from your factory. Static pressure

should be 65 psi min.; operating

pressure should be 45 psi min.

Replace the regulator if defective.

No power to the level sensor Verify that power is being supplied to

the level sensor (LED not lit = no

power) and that the power cord is

installed properly.

Deflector bent Repair or replace.

No power to fill board Verify power to the control box and at

the board. Replace if needed.

Solenoid failure Verify the connections to the

solenoid. Replace if defective.

Bad fill board Replace. See Refill PCA

Troubleshooting Instructions shown

later in the Troubleshooting section.

Overfill timer too short Adjust timer.

Sensor not calibrated properly Calibrate the sensor. Refer to Level

Sensor Adjustment and Calibration

provided earlier.

3. Frequent overfill

alarms with no cause

Timers not properly set Adjust the timer settings. See Time

Settings

provided earlier.

Loading...

Loading...