64

ODB COMPANY

800-446-9823 LCT6000

Service Section

5.4 Impeller Installation and Removal, continued

Before removing the blower housing

face remove the negative battery cable to

ensure unit can not be started.

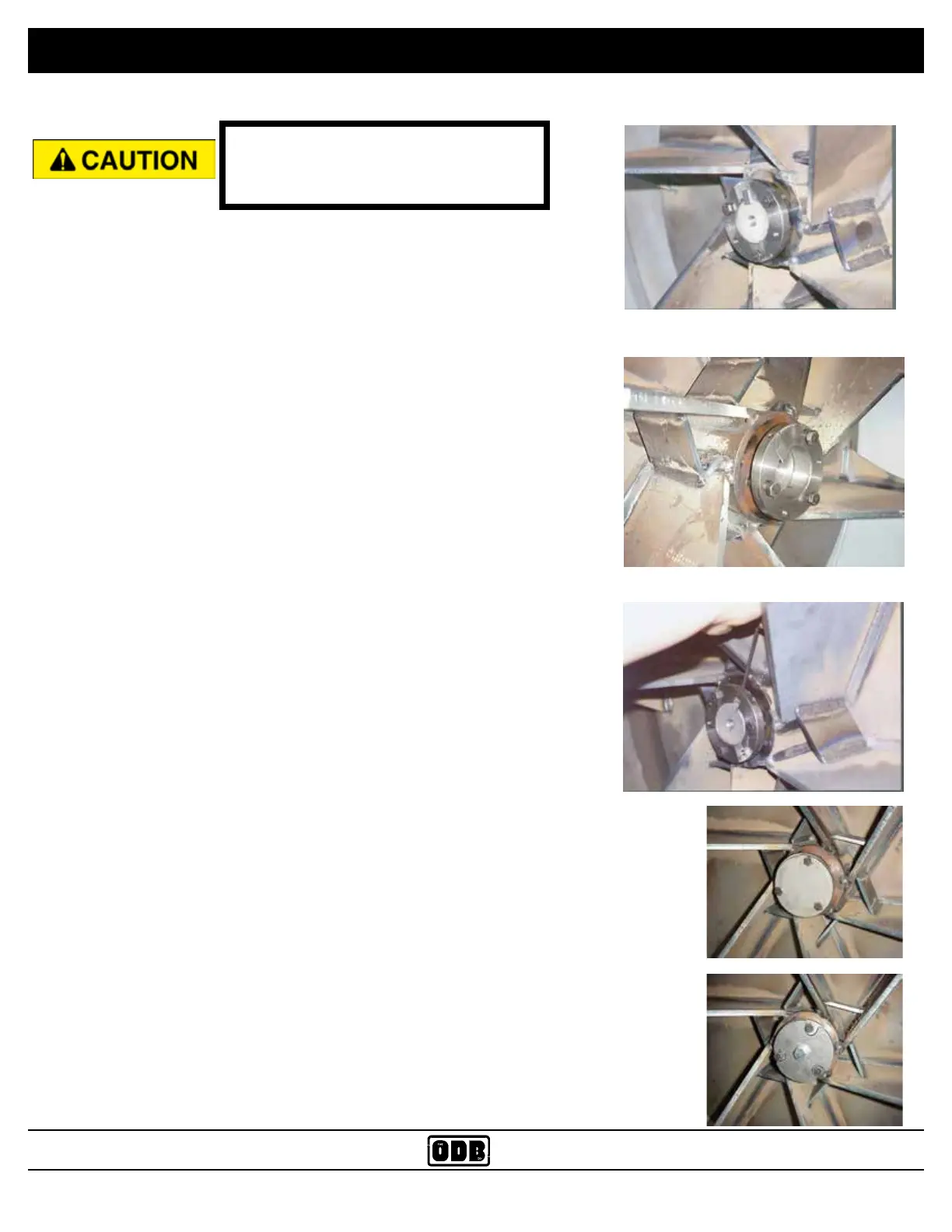

Fig. 1

Fig. 2

Fig. 3

Direct

Drive

Belt

Drive

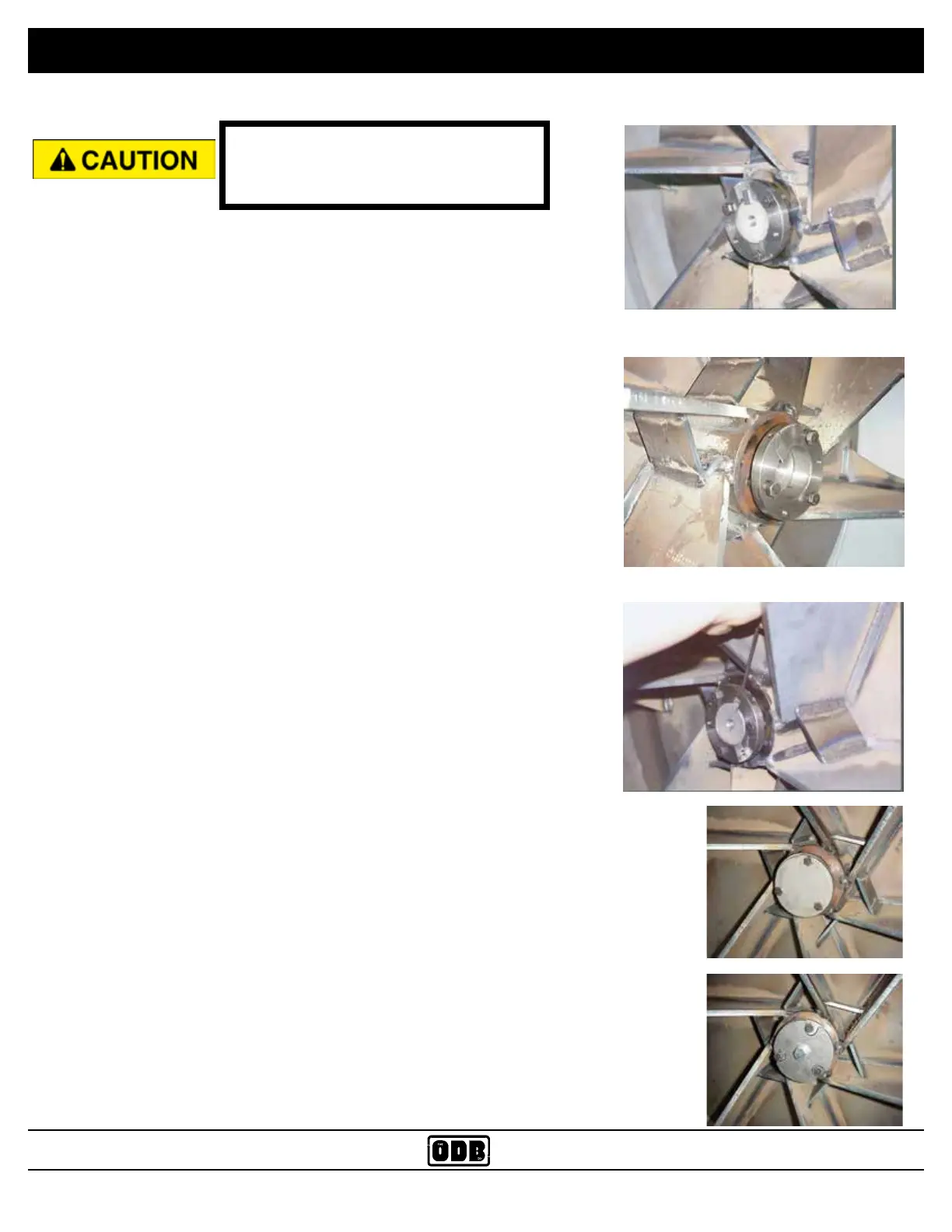

Fig. 4

Fig. 5

INSTALLATION

1. Clean the shaft of any debris and remove any rust using a 120 grit

emory cloth.

2. Using an overhead crane or other suitable lifting device lift the impel-

ler on to the shaft. Turn the impeller to align the keyways of the shaft

with the keyway in the impeller.

3. Insert key into the keyway. A light sanding of the keyway may be

needed, as well as a few light blows with a rubber mallet.

4. Tap the bushing onto the shaft aligning the keyways.

5. BELT DRIVE UNITS: Align the bushing and key to be ush with the

end of the shaft (Fig 1).

6. DIRECT DRIVE UNITS: The bushing and key should protrude from

the shaft about 1/2 inch (Fig. 2).

7. Put the 3 bolts into the non-threaded holes and drive them into the

impeller holes evenly. Alternate between the three bolts as you drive

the bolts in. Torque to 40 to 50 lbs/ft. There should be a gap of 3/8”

to 1/2” between the bushing and the impeller.

IMPORTANT: Slowly spin the impeller by hand making sure that the

back of the impeller is not hitting any of the bolt heads located at the

back of the blower housing.

8. If the bushing has a set screw on it, tighten the screw snug with an

allen wrench (Fig. 3). This will help keep the key in place.

9. Install the shaft protector on to the shaft (Fig. 4 or 5).

Loading...

Loading...