49

ODB COMPANY

800-446-9823 LCT6000

Maintenance Section

4.3 Lubrication:

Remove the negative battery terminal before attempting any

lubrication procedures.

oroughly read and understand the safety and pre-operat-

ing sections of this manual before performing any lubrica-

tion procedures.

NOTE; DO NOT mix different types

of grease. The old grease MUST

BE purged before a different type

of grease is used. Mixing grease

WILL cause premature failure to the

bearings.

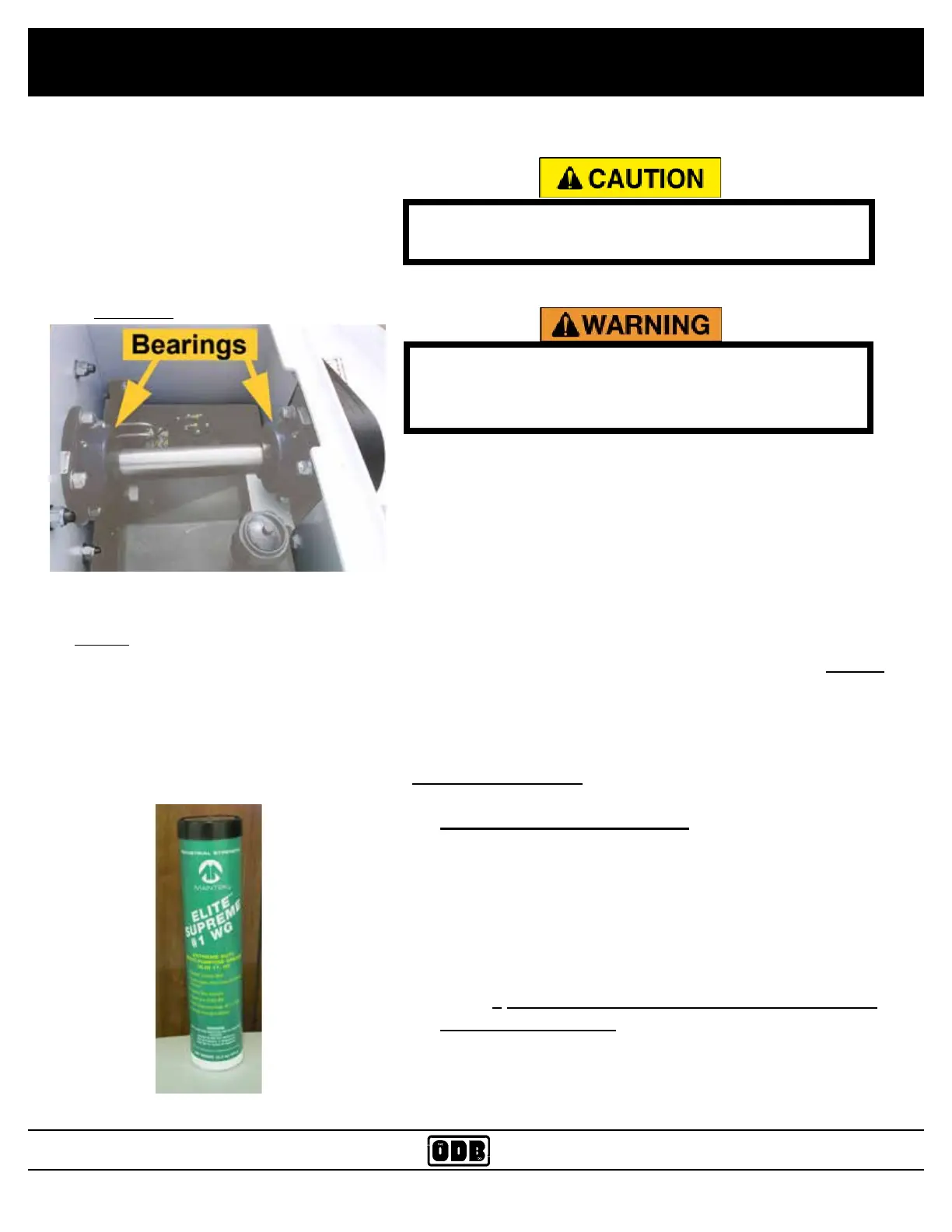

Figure 4.3A

The following are general lubrication procedures for our

standard units. Any special or custom built units may have

other lubrication procedures not directly mentioned in this

manual. Please consult the factory or your dealer before

any lubricating procedures not specically mentioned in this

manual.

Proper lubrication of your unit correlates directly to how long

your unit will last. A properly maintained unit will last much

longer than a unit that is not maintained properly. NOTE:

Always lubricate bearings at the end of each work day. This

will displace any moisture in the bearings. Also lubricate

thorougly before extended shutdown or storage.

Lubrication Points:

1. Drive Bearings (gure 4.3a): These bearings are criti-

cal components of the belt-driven units. These bearings

should be greased every 10 hours with approximately

two strokes from the average hand pump grease gun.

The type of grease used in these bearings are also

critical to the performance of the bearings. A multi-pur-

pose, heavy-load, high-temperature, moisture resistant

#2 grease is required for the drive bearings. We recom-

mend L Mantek Elite Supreme #1 WG Extreme Duty

multi-purpose grease. Other premium quality grease that

matches the above requirements may be used but after

years of testing we recommends the Mantek grease.

Loading...

Loading...