50

ODB COMPANY

800-446-9823 LCT6000

Maintenance Section

Figure 4.3b

4.3 Lubrcation, continued;

Grease tting is behind rubber plug

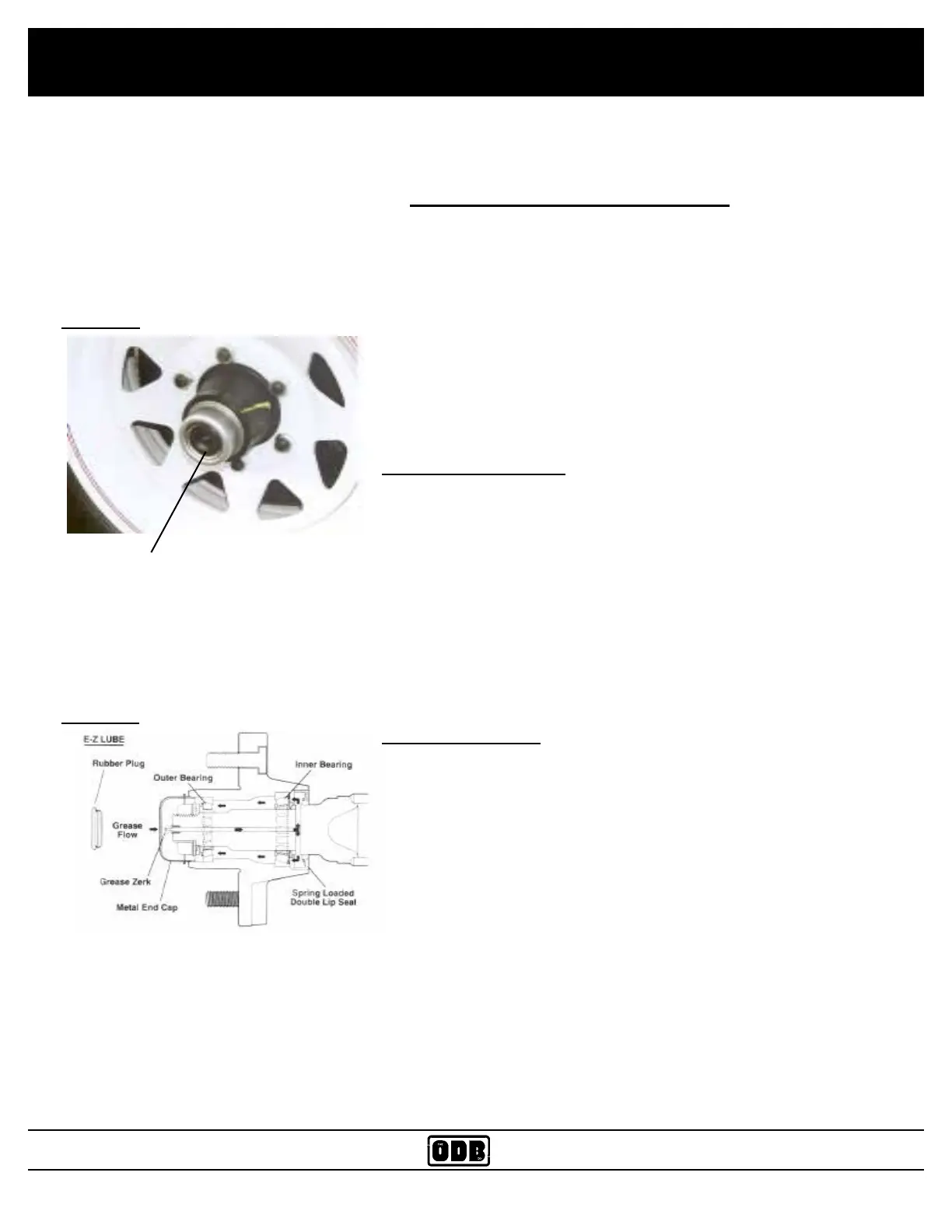

Figure 4.3c

2. Trailer Wheel Bearings (gure 4.3b): Most of the units

are equipped with "EZ-Lube" grease ttings. This allows the

operator to grease the bearings without removing the hubs.

The "EZ-Lube" feature consists of axle spindles that have

been specially drilled and tted with a grease zerk in their

ends (g. 4.3c). When grease is pumped into the zerk, it is

channelled to the inner bearing and then ows back to the

outer bearing and eventually back out the grease cap hole.

The trailer wheel bearings should be checked and greased

after the rst 30 days of service then at the beginning of

every season.

Grease specications:

Thickener Point............................Lithium Complex

Dropping Point......................230 degr. C minimum

Consistency............................................NLGI No.2

Additives.........................EP,Corrosion & Oxidation

Inhibitors

Base Oil...................Solvent rened Petroleum Oil

Base Oil Viscosity............@40 deg. C 150cSt Min.

Viscosity Index.....................................80 Minimum

Pour Point...................................-10 deg. Minimum

Approved Sources:

Mobil Oil........................................Mobilgrease HP

Exxon/Standard......................................Ronex MP

Kendall Rening...............................Kendall L-427

Ashland Oil Co........Valvoline Val-plex EP Grease.

Penzoil.......Premium Wheel Bearing Grease 707L

For any questions concerning wheel lubrication please consult

the axle owner's manual supplied with your leaf collector or con-

tact the manufacturer or dealer.

Loading...

Loading...