51

ODB COMPANY

800-446-9823 LCT6000

Maintenance Section

4.3 Lubrication, continued;

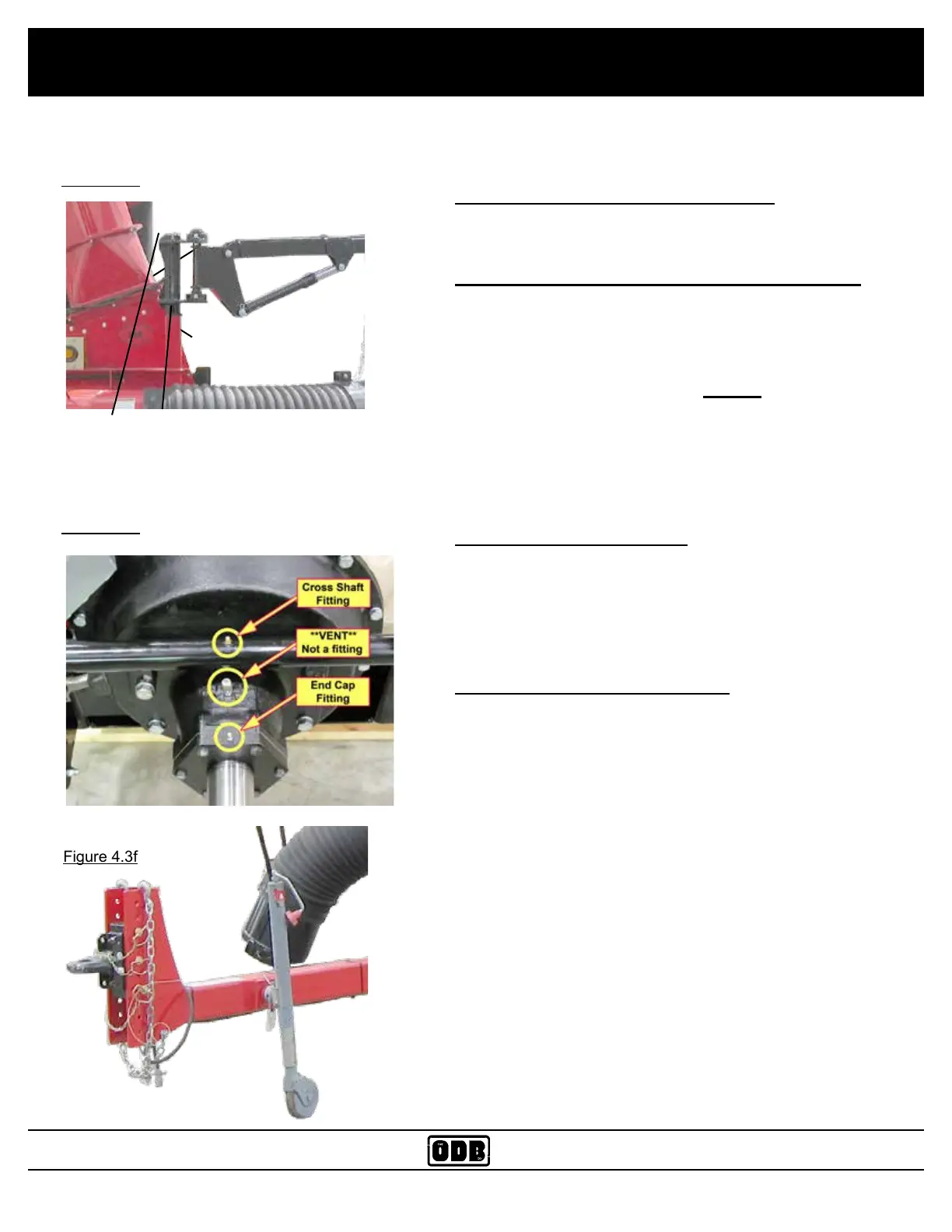

Figure 4.3d

One tting on each bearing

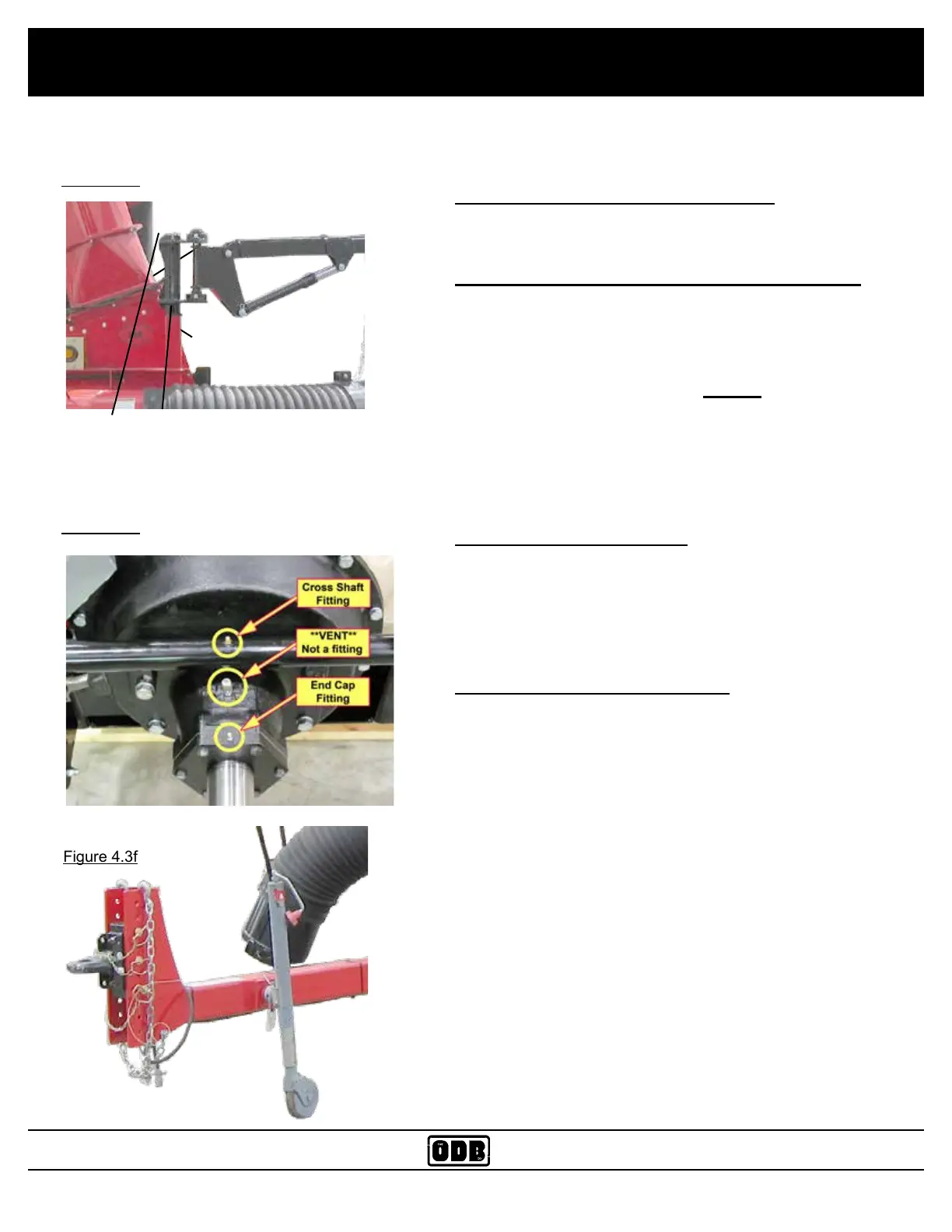

Figure 4.3e

Figure 4.3f

3. Boom Swivel Bearings (gure 4.3d): Grease the

boom bearings once every week with a multi-purpose

moisture resistant #2 grease.

4. PTO Bearing & PTO Shaft Fitting (gure 4.3e):The

PTO bearings should be greased after every 50 hours

of operation with a high grade, high temperature lithium

base #2 lubricant having an operating temperature of

200 degrees F. Three to ve pumps with a hand oper-

ated grease gun is sufcient. NOTE: Units manufac-

tured after 2000 may not have a PTO bearing grease

tting. These bearings are sealed and do not require

greasing. The PTO crossover shaft and linkage should

be lubricated with high temperature lithium base #2

lubricant after 200 hours of operation.

5. Hinge and Friction Points: Leaf vacuum operation

and longevity can be improved by keeping hinges and

friction points lubricated. It is recommended that lubri-

caton be performed weekly. Use SAE30 weight oil on

hinges and a premium grade, high temperature lithium

based EP#2 grease on friction points.

6. Hitch and Tongue (gure 4.3f): The hitch and hitch

ring should be checked and lubricated daily to minimize

wear. Apply grease and/or SAE30 weight oil wherever

applicable.

Loading...

Loading...