Field Service Ver. 2.0 Jul. 2009 12. SERVICE MODE

465

ADJUSTMENT / SETTING

12.4.5 Printer Area-Leading Edge Adjustment

A. Use

• To vary the print start position in the sub scan direction for each of different paper types.

(To adjust the timing where paper is sent out from the timing roller)

• The PH unit has been replaced.

• The paper type has been changed.

• The print image deviates in the sub scan direction.

• A faint image occurs on the leading edge of the image.

• This setting can be made independently for plain paper, Thick 1/1+, Thick 2, Thick 3,

Thick 4, OHP transparencies, and envelopes.

B. Procedure

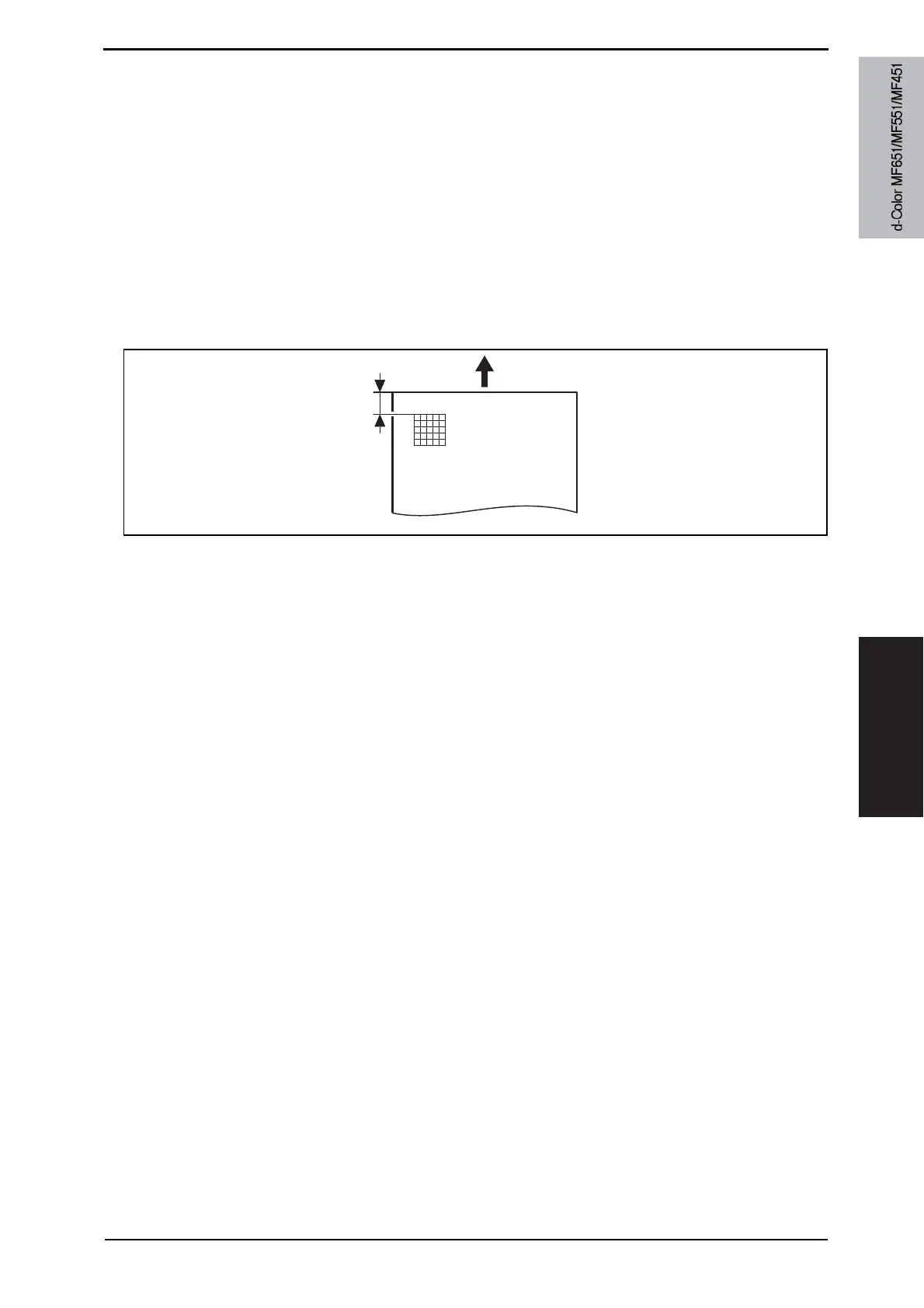

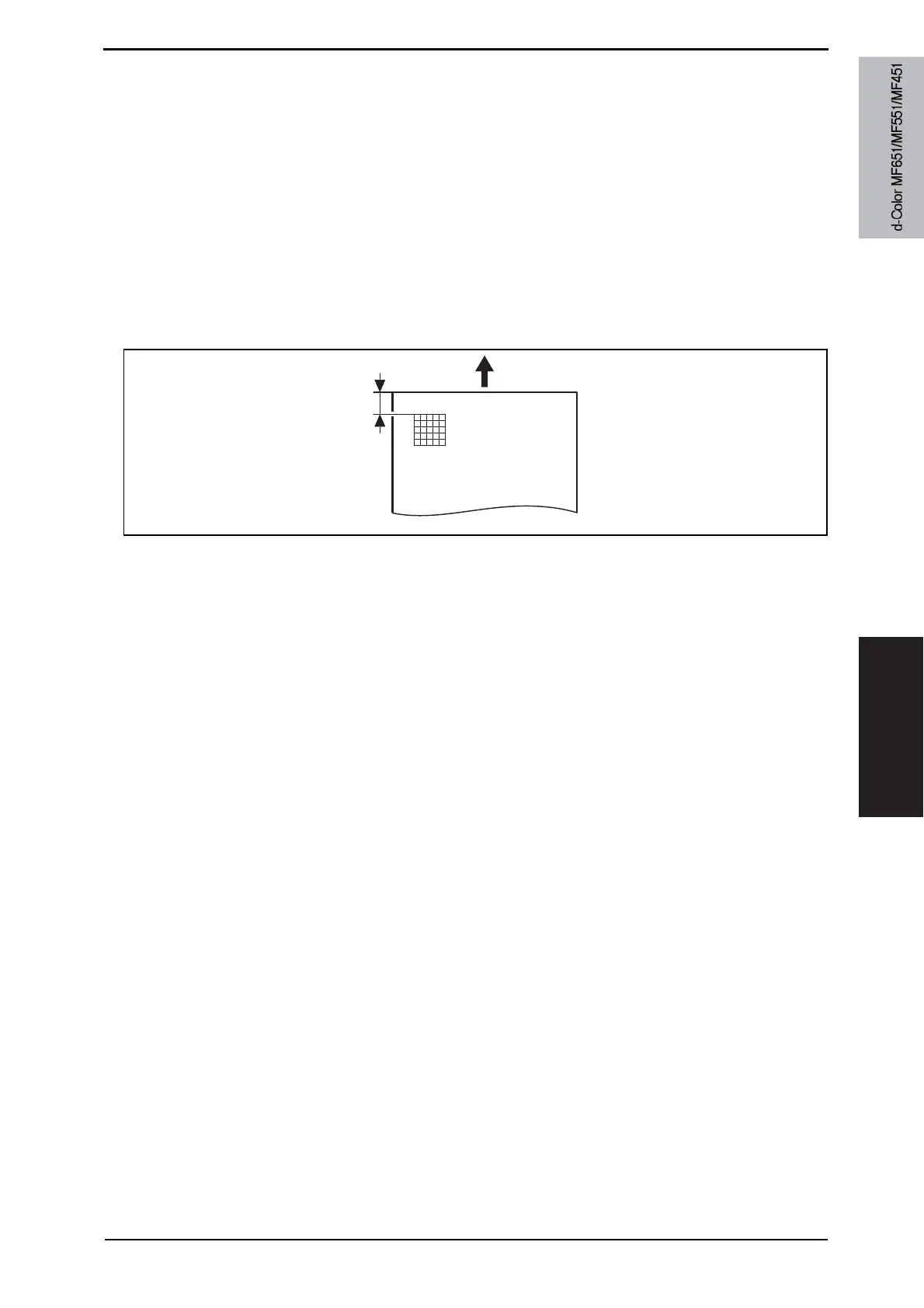

• Width A on the test pattern produced should fall within the following range.

Specifications: 4.2 r 0.5 mm

1. Place A3 paper on the manual bypass tray.

2. Call the Service Mode to the screen.

3. Touch [Machine] o [Printer Area] o [Leading Edge Adjustment].

4. Select the [Plain Paper].

5. Press the Start key to let the machine produce a test print.

6. Check the dimension of width A on the test print.

7. If width A falls outside the specified range, change the setting using the [+] / [-] key.

If width A is longer than the specifications, make the setting value smaller than the cur-

rent one.

If width A is shorter than the specifications, make the setting value greater than the cur-

rent one.

8. Press the Start key to let the machine prod

uce a test print.

9. Check the dimension of width A on the test print.

10. If width A is outside the specified range, change the setting again and make a check

again.

11. If width A falls within the specified range, touch [END].

12. Following the same procedure, adjust for Thick 1 to 3, OHP film, and Enve.

A0P0F3C503DA

Width A

Y110571-1 Service Manual

Loading...

Loading...