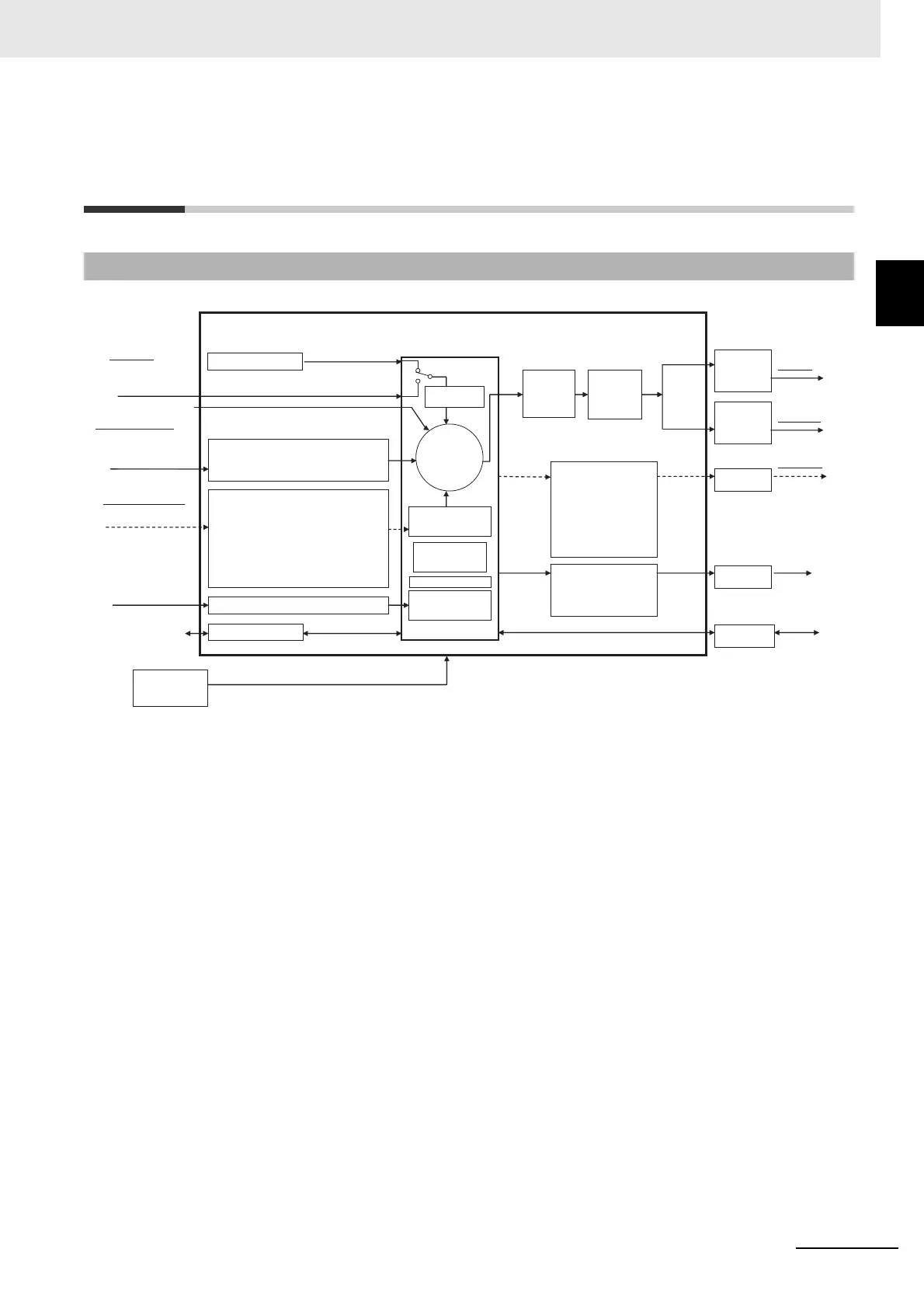

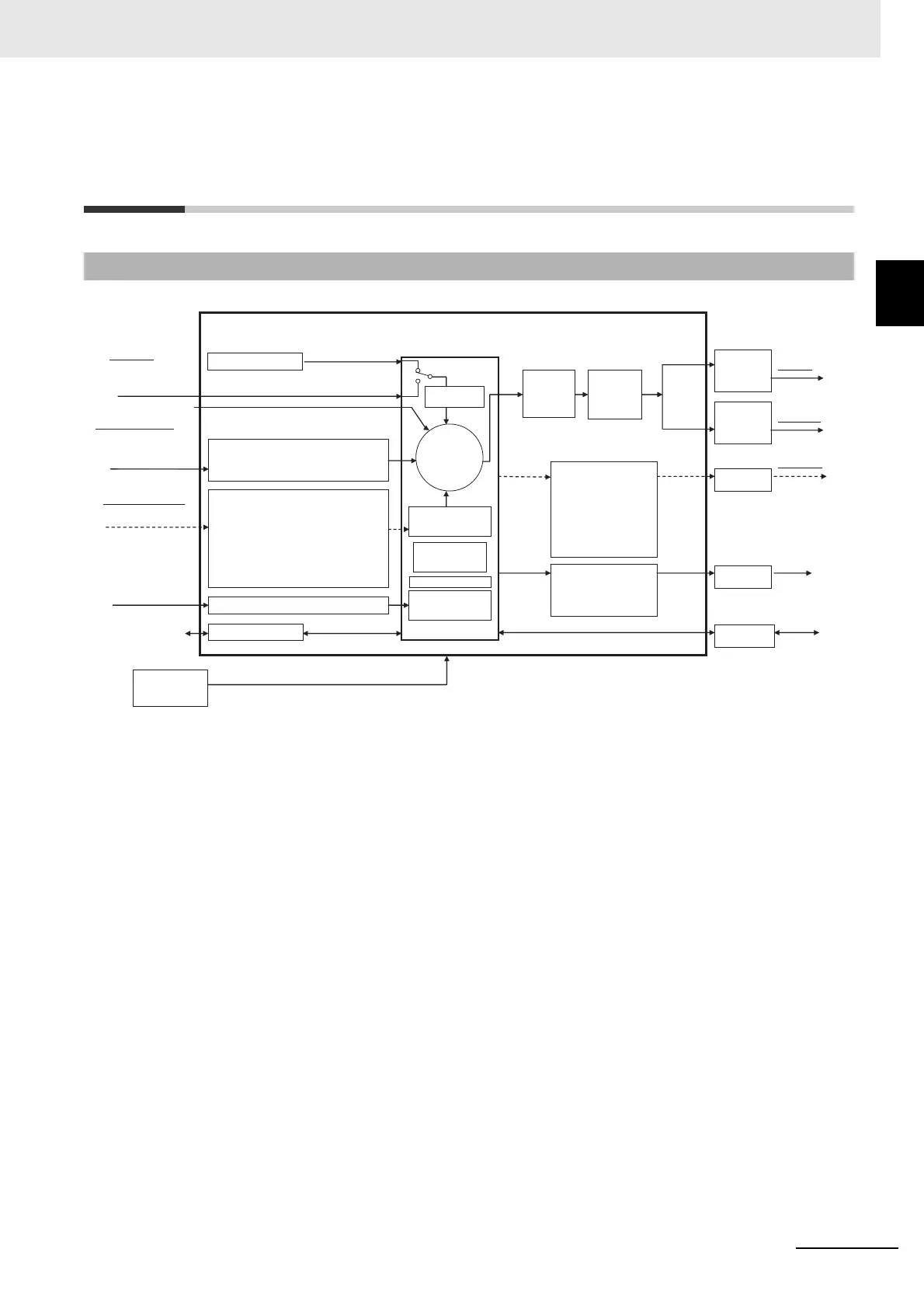

E5@C

Auxiliary outputs 1 to 4

• Input type • Input shift

• Input filter • Moving average

• Extraction of square root • Analog scaling

Input signals

Event inputs (EV1 to EV6)

• External inputs

(contact or non-contact input)

Setting and monitoring

• Direct/reverse

• Auto/manual

• Linear current

• Voltage output

(for driving SSR)

• Relay

Outputs

• RS-485

PV

•

Standard alarms (alarms 1 to 4)

• HB alarm

• HS alarm

• Input error (S.ERR)

•

RSP input error

•

Integrated alarm

•

RUN status

•

Program end

•

Work bits 1 to 8

Manipulated

value

(MV)

Setup Tool (CX-Thermo)

Limits

Output signals

A: 100 to 240 VAC

or

D: 24 VAC/DC

• CompoWay/F

• Modbus-RTU

Communications

• Linear current

• Linear voltage

Transfer output

CT input

Multi-SP

Input voltage from CT

Inputs

Set point (SP)

Local SP

Analog input (current/voltage)

Control

• HB alarm

• HS alarm

Alarms

Power supply

• Set point

• Set point during SP ramp

• Process value

• Manipulated value

• Relay

Analog status

Control output 1

Contact status

Operation

Process value (PV) input

• Thermocouple

• Resistance thermometer

• Infrared Temperature Sensor

• Analog input (current/voltage)

• Linear current

• Voltage output

(for driving SSR)

• Relay

Control output 2

• PID or

• ON/OFF control

Cooling

Close

*

*

*

Remote SP

SP mode

SP

• RUN/STOP switching •

Auto/manual selection

• Program start

•

100% AT execute/cancel

• 40% AT execute/cancel

• Alarm latch cancel • Multi-SP No.

• SP ramp

• Set point limiter

• Invert direct/reverse

operation

• SP mode

(remote/local

switching)

• Setting change

enable/disable

• Communications

write enable/disable

• Standard control or

• Heating/cooling

control

Automatic setting of

PID constants with AT

or ST

• MV limit

• MV

rate-of-

change limit

*

Functions can be assigned individually for each output by

changing the set values for the Control Output 1 and 2

Assignments and the Auxiliary Output 1 to 4 Assignments in the

parameters in the advanced function setting level.

Potentiometer input

Heating

Open

FB

Loading...

Loading...