263

Appendix

Note The tightening torque for E5CN-U is 0.5 N·m.

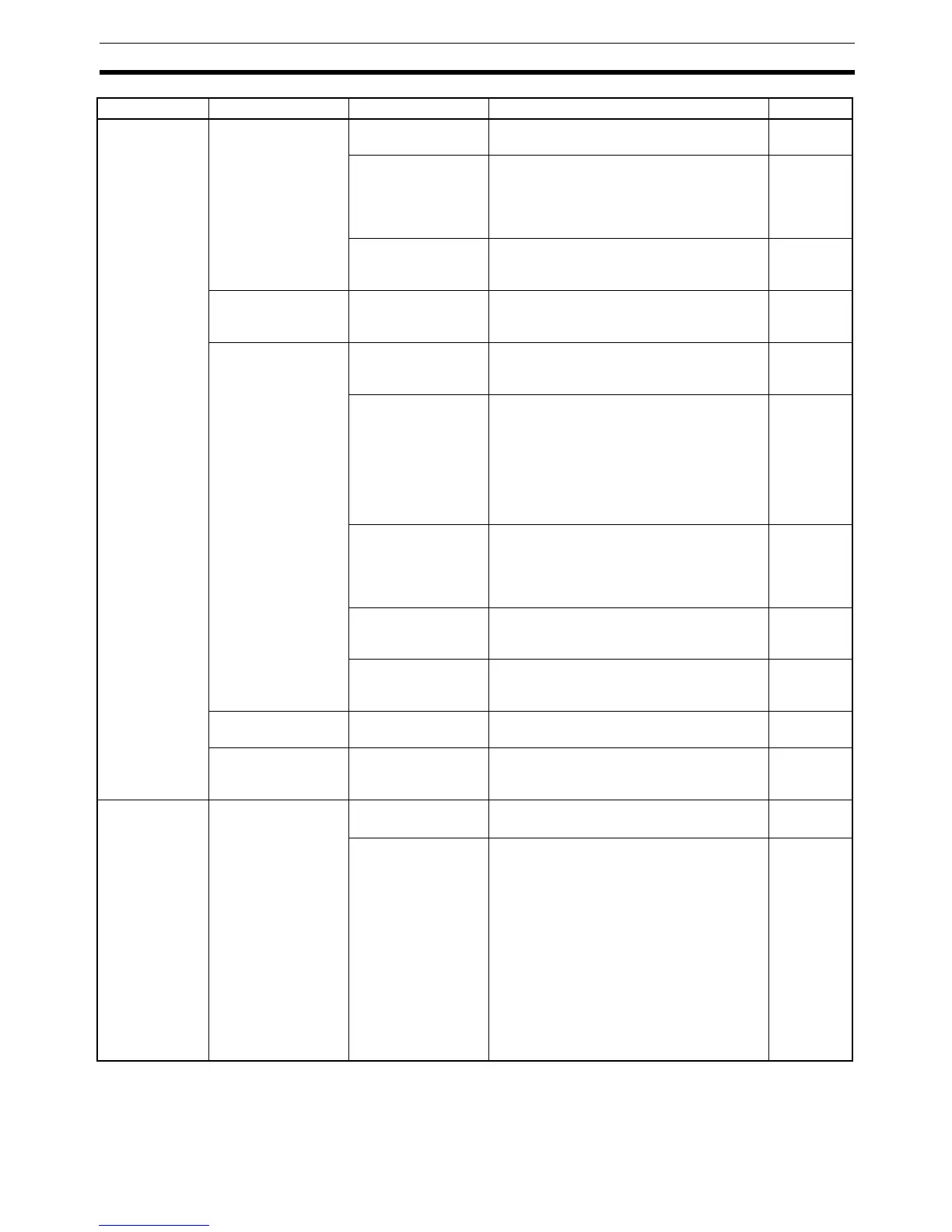

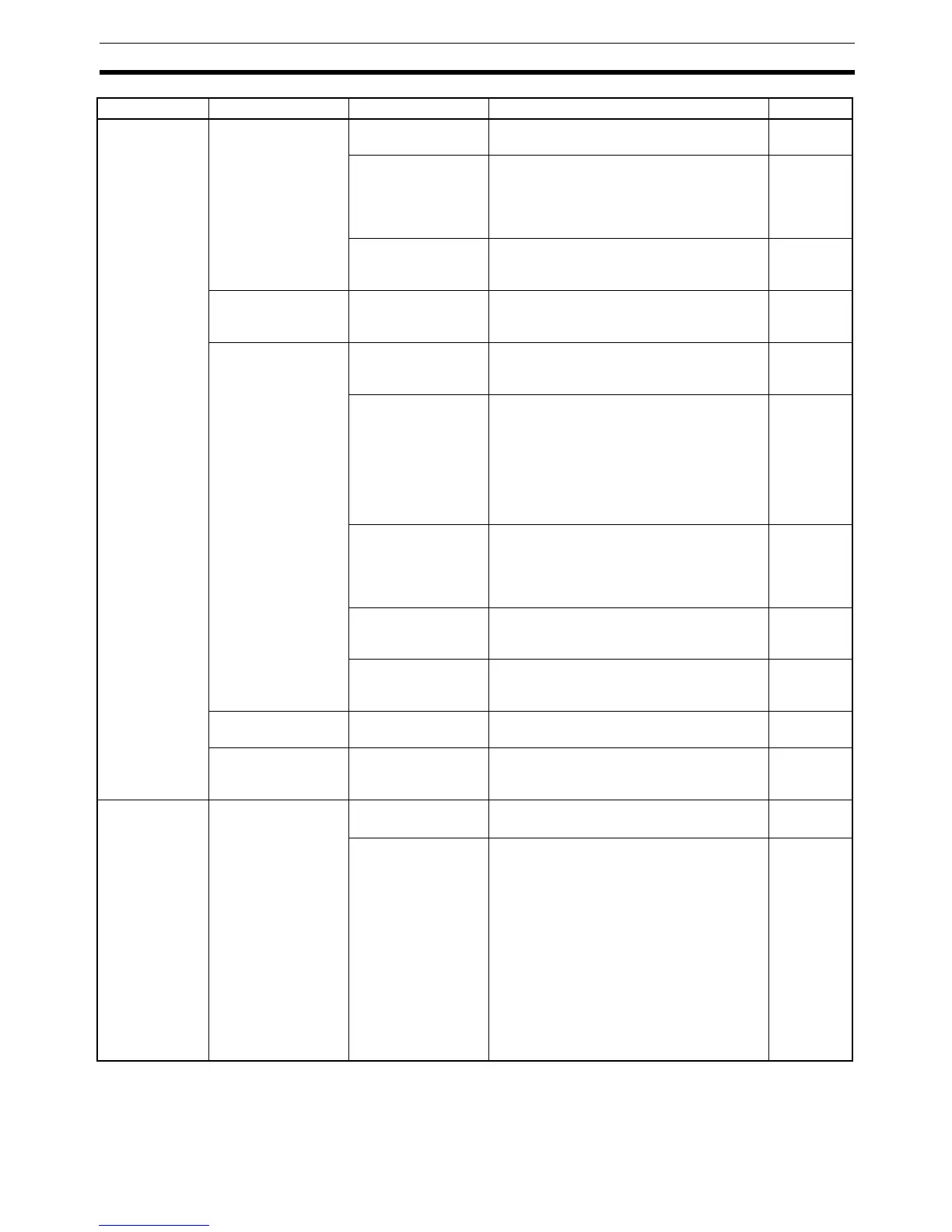

During opera-

tion (continued)

Output will not turn

ON

Set to STOP

(default: RUN)

Set the RUN/STOP mode to RUN. If STOP

is lit on the display, control is stopped.

156

Specified operation

is unsuitable for

required control

(default: Reverse

operation)

Select either forward or reverse operation

depending on the required control. Reverse

operation is used for heating operations.

42

A high hysteresis is

set for ON/OFF oper-

ation (default: 1.0°C)

Set a suitable value for the hysteresis. 48

Temperature Con-

troller will not oper-

ate

Set to STOP

(default: RUN)

Set the RUN/STOP mode to RUN. If STOP

is lit on the display, control is stopped.

156

Temperature error is

large

Input error (S.err dis-

play)

Thermometer has

burnt out or short-cir-

cuited.

Check whether the thermometer has burnt

out or short-circuited

---

Thermometer lead

wires and power

lines are in the same

conduit, causing

noise from the power

lines (generally, dis-

play values will be

unstable).

Wire the lead wires and power lines in sep-

arate conduits, or wiring using a more direct

path.

---

Connection between

the Temperature

Controller and ther-

mocouple is using

copper wires.

Connect the thermocouple’s lead wires

directly, or connect a compensating conduc-

tor suitable for the thermocouple.

---

Installation location

of thermometer is

unsuitable.

Check whether the location of the thermom-

eter is suitable.

---

Input shift is not set

correctly (default:

0°C)

Set a suitable input shift. If input shift is not

required, set the input shift value to 3.

77

Keys will not operate Setting change pro-

tect is ON.

Turn OFF setting change protect. 96

Cannot shift levels Operations limited

due to protection.

Set the operation/adjustment protect, initial

setting/communications protect, and set-

ting change protect values as required.

96

After long ser-

vice life

Control is unstable Terminal screws may

be loose.

Retighten terminal screws to a torque of

0.74 to 0.90 N

·m (see note).

26

The internal compo-

nents have reached

the end of their ser-

vice life.

The Temperature Controller’s internal elec-

trolytic capacitor depends on the ambient

temperature, and load rate. The structural

life depends on the ambient environment

(shock, vibration). The life expectancy of the

output relays varies greatly with the switch-

ing capacity and other switching conditions.

Always use the output relays within their

rated load and electrical life expectancy. If

an output relay is used beyond its life

expectancy, its contacts may become

welded or burned. Replace the Temperature

Controller and all other Temperature Con-

trollers purchased in the same time period.

---

Timing Status Meaning Countermeasures Page

Loading...

Loading...