5-8

CHAPTER 5 Periodic Inspection

5 Replacing the Harmonic Drive

The XC series robots use a harmonic drive as the speed reduction gear for the X,

Y and R axes. Harmonic drives need to be replaced after a specied operation

time. Use the guideline explained below to determine the replacement period

and replace the harmonic drive periodically.

Since the XC series robots use long-life harmonic grease, it is not necessary to

replace the harmonic grease.

5-1 Replacement period

The harmonic drive replacement period is determined by the total number of

turns of the wave generator used in the harmonic drive. It is recommended to

replace the harmonic drive when the total number of turns has reached 8.4×10

8

(at ambient operating temperatures of 0°C to +40°C). This means that the

replacement period will differ depending on the following operating conditions.

If the robot operation duty ratio is high or the robot is operated in environments

at higher temperatures, the harmonic drive should be replaced earlier.

Replacement period = 8.4×10

8

/(n×60×h×D×N×θ) years

where n : Number of axis movements per minute

θ : Average turn per axis movement

N : Speed reduction ratio

h : Operation time per day

D : Operation days per year

For example, when the robot is used under the following conditions, the replace-

ment period for the X-axis harmonic drive of the R6YXC500 can be calculated as

follows.

n : 10

θ : 0.25

N : 80

h : 24 hours per day

D : 240 days per year

Replacement period = 8.4×10

8

/(n×60×h×D×N×θ)

= 8.4×10

8

/(10×60×24×240×80×0.25)

= 12.2 years

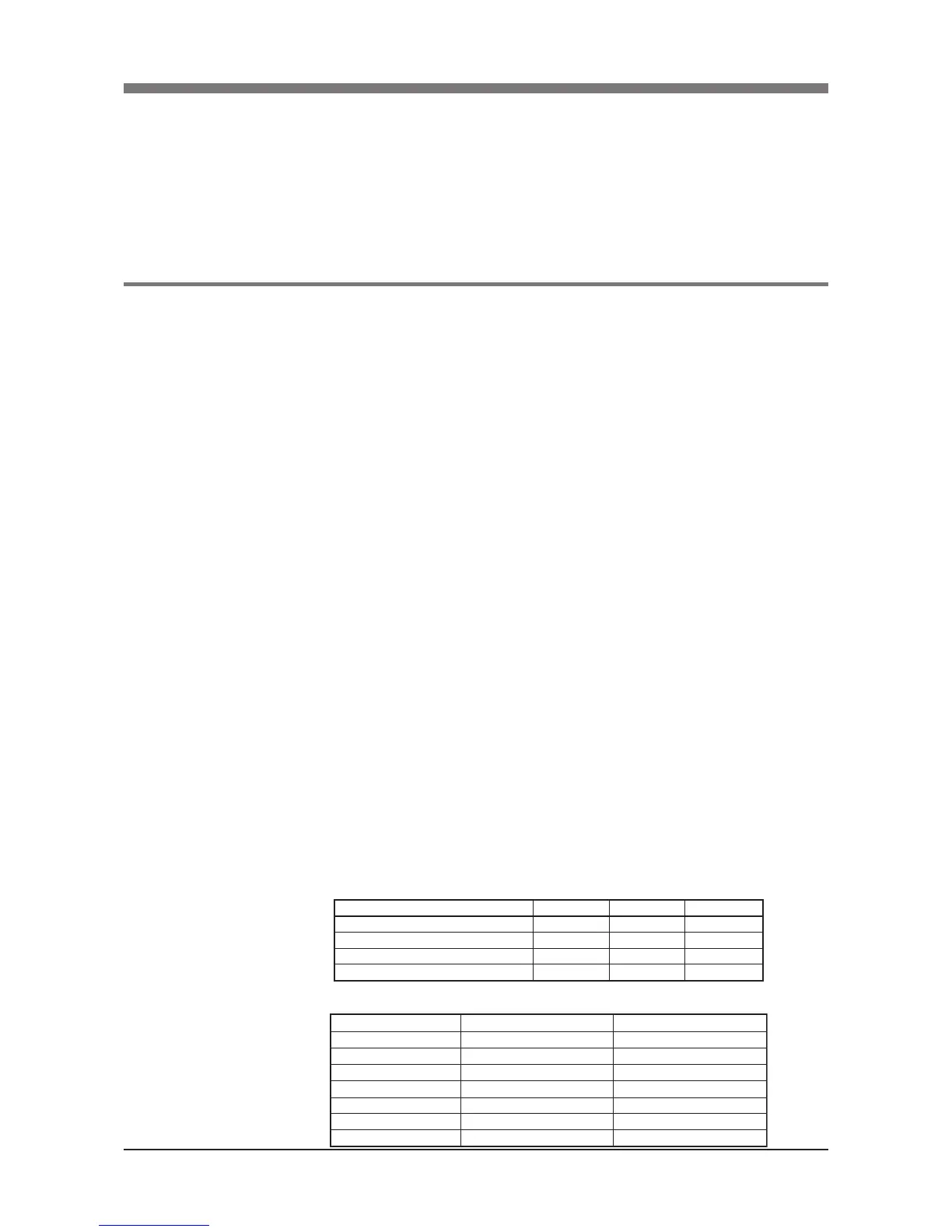

Table 5-1 Harmonic drive speed reduction ratio

Loading...

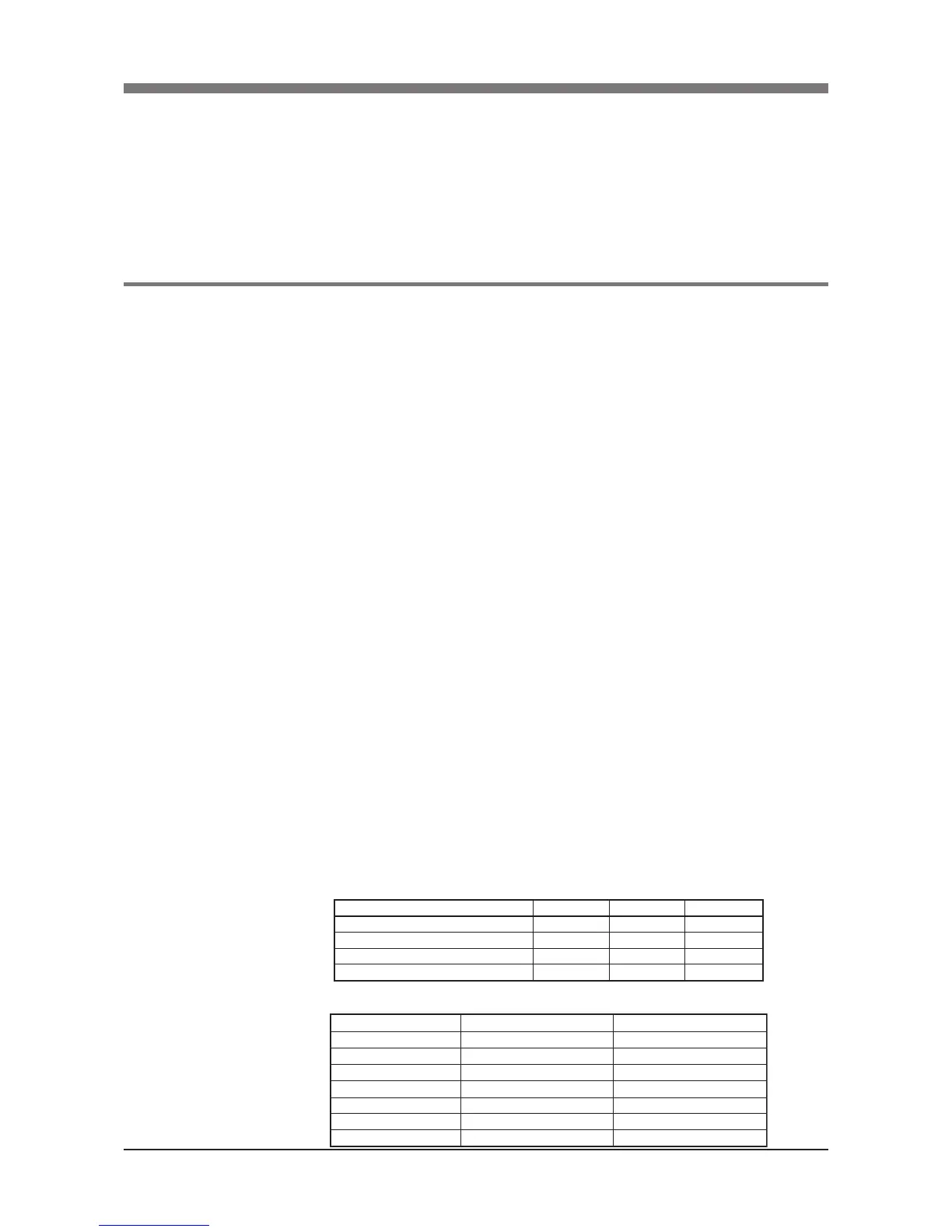

Loading...