Operation

43

DTX-2200-3000 AC/DC

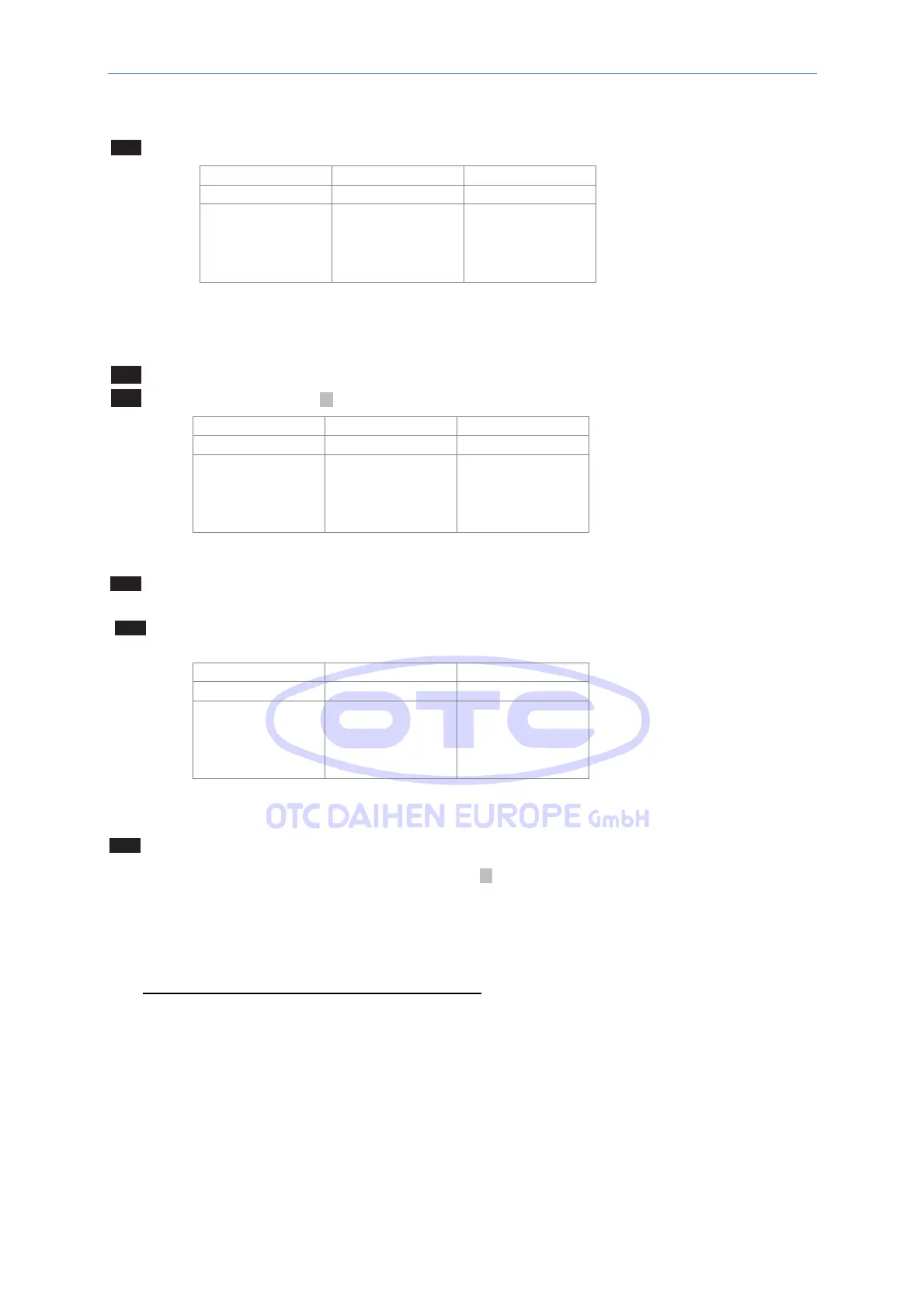

L18 INITIAL welding CURRENT

2200 AC/DC 3000 AC/DC

TIG DC 5 - 220 A 5 - 300 A

TIG

AC

DYNAMIC TIG

SPEED TIG

COLD TIG

SOFT TIG

5 - 220 A

5 - 220 A

16 - 127 A

16 - 156 A

5 - 300 A

5 - 300 A

5 - 173 A

5 - 212 A

WARNING: This can only be programmed when 4 STROKES or Bi-Level welding mode is activated.

L13 SLOPE UP

duration

(0,0 - 5,0 Sec.)

L11 Main welding current I

1

2200 AC/DC 3000 AC/DC

TIG DC 5 - 220 A 5 - 300 A

TIG

AC

DYNAMIC TIG

SPEED TIG

COLD TIG

SOFT TIG

5 - 220 A

5 - 220 A

16 - 127 A

16 - 156 A

5 - 300 A

5 - 300 A

5 - 173 A

5 - 212 A

L16 SLOPE DOWN

duration

(0,0 - 8,0 Sec.)

L22 FINAL welding CURRENT

2200 AC/DC 3000 AC/DC

TIG DC 5 - 220 A 5 - 300 A

TIG

AC

DYNAMIC TIG

SPEED TIG

COLD TIG

SOFT TIG

5 - 220 A

5 - 220 A

16 - 127 A

16 - 156 A

5 - 300 A

5 - 300 A

5 - 173 A

5 - 212 A

WARNING: This can only be programmed when 4 STROKES or Bi-Level welding mode is activated.

L17 POST GAS duration (0,5 - 25,0 Sek.)

WARNING: When the post-gas LED flashes and the LED I

1

is on at the same time, this means that the welding

machine is in the post-gas stage.

To exit the setting phase, hold the WELDING PARAMETERS SE- LECTION key (T10) down for about 1 second.

2. WELDING PARAMETERS with PULSE mode active

Pulsed TIG welding allows greater control of the arc and better de- formation of the material.

The DTX HF can be used for TIG pulsed welding in 4 different modes:

• SLOW PULSE

• FAST PULSE

• ULTRA FAST PULSE

• SYN PULSE

WARNING: Pulsation is deactivated automatically for the duration of the INITIAL and FINAL current.

Loading...

Loading...