37

Reducing the required space

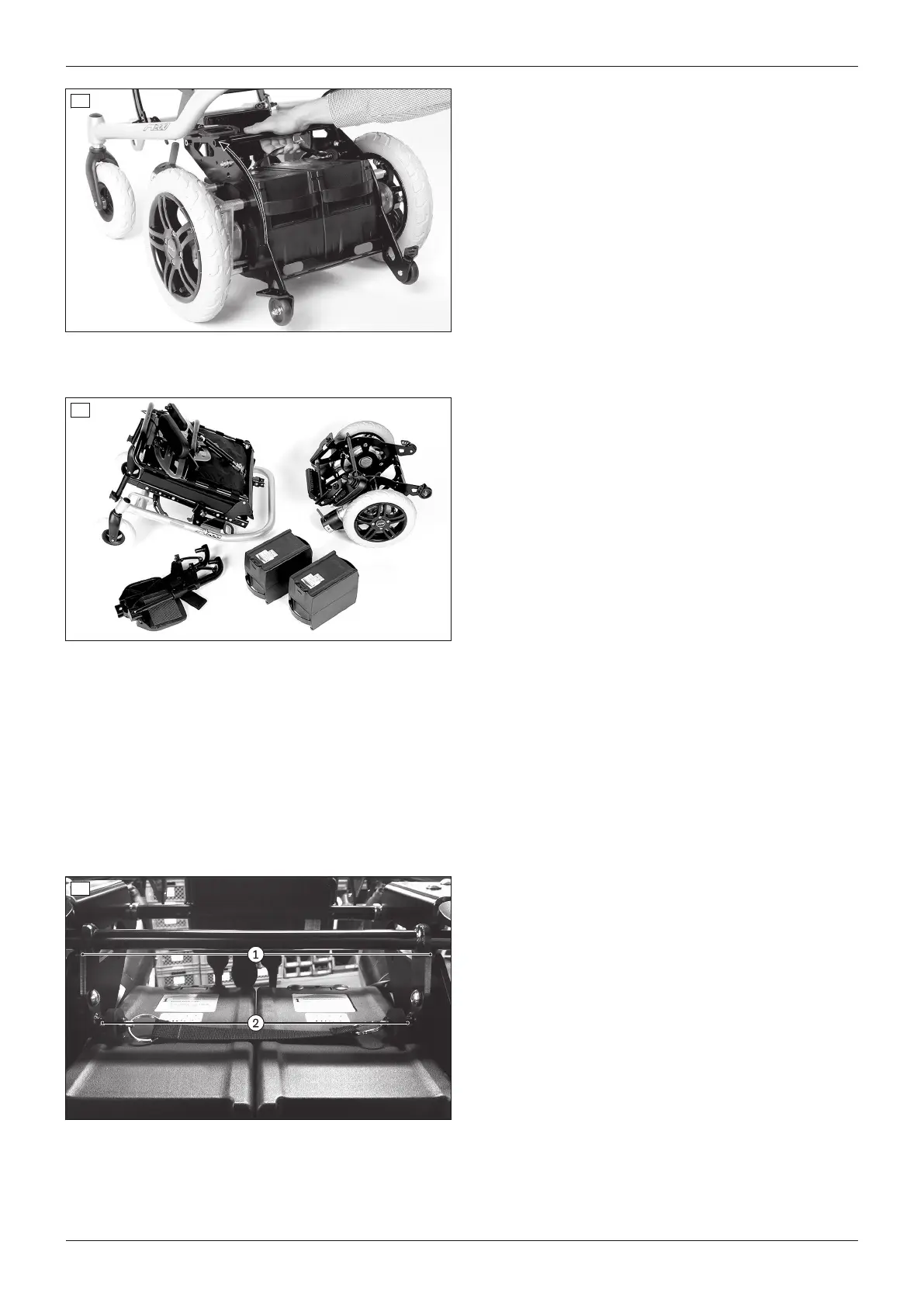

1) Set the battery packs back into the drive unit brack

et.

INFORMATION: Ensure that the red arrows on

the battery packs point forward.

2) Fold the lock lever up again to prevent the battery

packs from falling out (see fig.37).

3) If needed: Lay the control panel on top of the bat

tery packs (not illustrated) or insert it into the cor

responding holder.

INFORMATION: Ensure that the control panel is

not switched on and that cables are not

pinched.

→ Now the power wheelchair is ready to transport

and can be stowed in a vehicle.

38

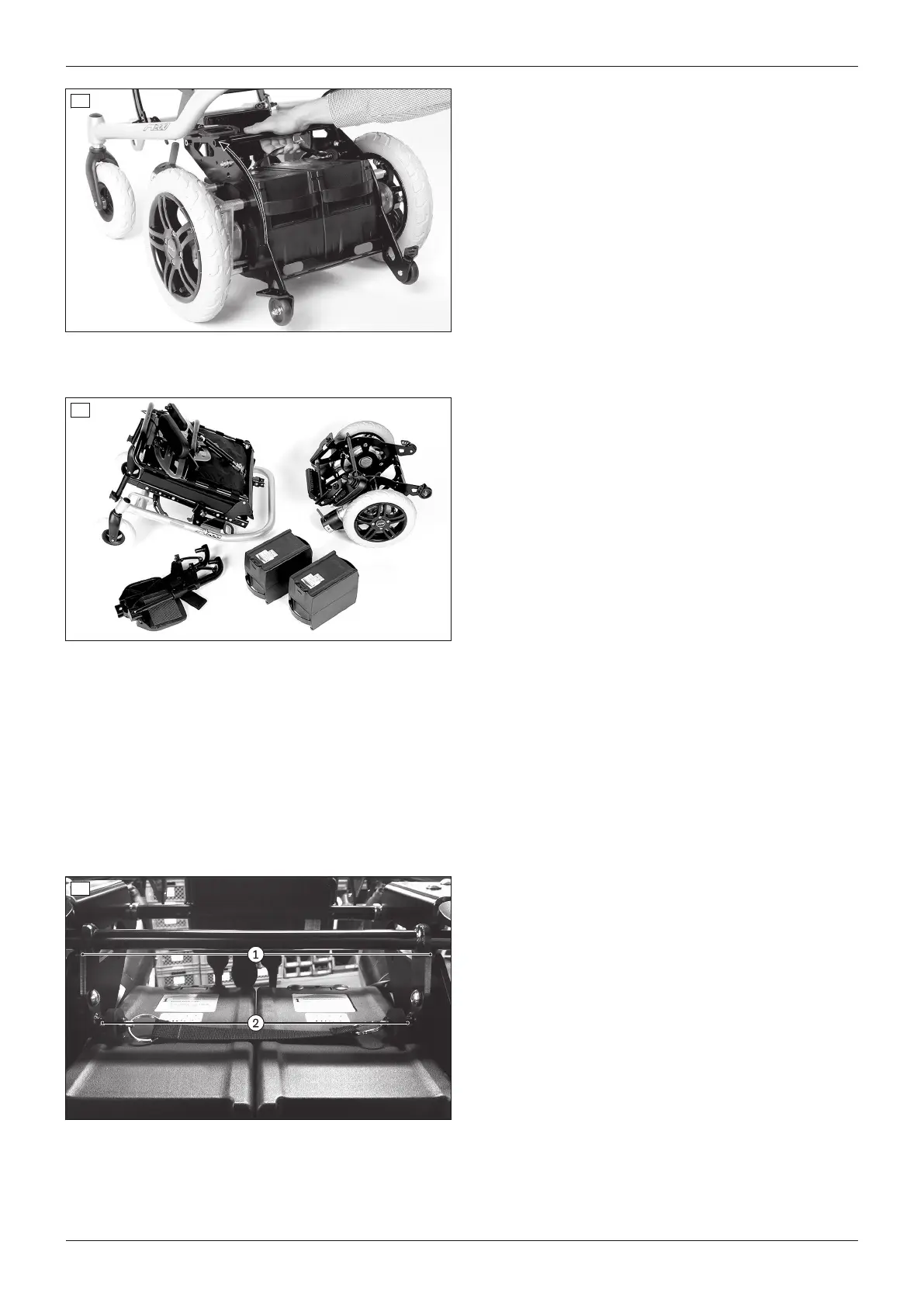

Disassembling the power wheelchair for transport

ation

The power wheelchair can also be fully disassembled

for transportation. This has the following advantages:

• It takes up very little transportation space.

• The power wheelchair disassembled into single

components is easier to handle.

• NOTICE: Secure the disassembled parts of the

power wheelchair properly so that they cannot

slide.

8.15.3 Preparing for transport

Transporting the power wheelchair as a whole

1) If needed: Turn the control unit off (see Page23).

2) If needed: Lock the brake (see Page30).

3) Use cargo straps to attach the power wheelchair to the transport vehicle.

8.15.4 Assembly

To reassemble the power wheelchair, the steps described above must be carried out in reverse order.

If the frame was separated from the drive unit bracket for transportation of the power wheelchair, correct locking of

the frame has to be ensured during assembly:

39

Connecting the frame to the drive unit bracket

1) Prepare the drive unit bracket and frame.

2) Pull the seat lock release strap and fold the locking

bar all the way down (see fig.34).

3) On the drive unit bracket, push down on the step

points (frame protection rollers) above the anti-tip

per rollers until these touch the ground (see fig.35,

left). The drive unit bracket is now at an angle.

4) Set the frame onto the drive unit bracket from above

(see fig.35, right).

45A200

Use

Loading...

Loading...