B-149-4N-E

13

9. OPERATING INSTRUCTIONS

9.1 Operation

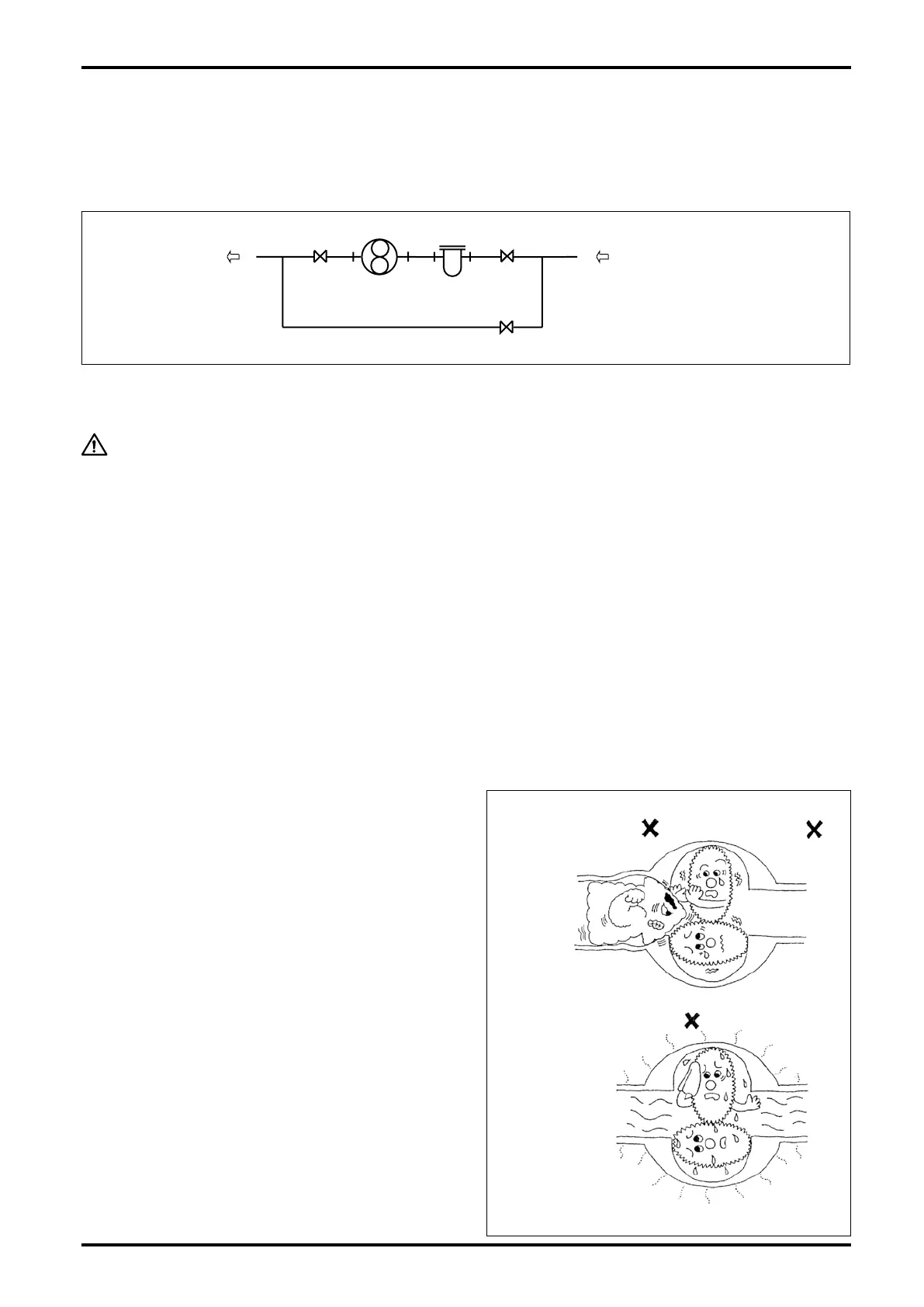

At rst-time operation, carefully operate in the following sequence, allowing the ow within the ow range

specied. (Refer to the piping diagram below.)

(1) Shut off the valve (A) on the inlet side and the valve (B) on the outlet side and then open the bypass line

valve (C) to allow the uid in the bypass line, thereby removing weld chips, scales and other foreign matter

left in the piping assembly.

CAUTION: This is particularly important on new installations.

(2) Carefully and slightly at rst, open the valve (A) upstream of the meter progressively and then, slightly at

rst, open the valve (B) downstream progressively.

(3) Slowly close the bypass line valve (C) and make sure that the total counter in the register advances in

response. Maintain a owrate 10 to 20% of the maximum owrate (conrm it in the instantaneous owrate

display mode) at this time, allow the ow for more than 15 minutes and make sure that air in the piping

assembly has totally escaped.

In applications where temperature exceeds 60°C, run the system at least for 30 minutes in this state to

ensure uniform heat distribution in the measuring chamber.

(4) Following the break-in operation (preheating), shut off the bypass line valve (C) completely and open the

upstream valve (A) progressively until fully open and slowly open the downstream valve (B) until the rated

ow is obtained.

(5) Flowrate should be regulated with the valve (B) downstream of the meter and should be held within the

rating.

(6) The strainer net should be inspected for condition and cleaned on a regular basis. On a new installation, in

particular, inspect daily rst and, according to the clogged condition of the net being observed, inspection

intervals may be reduced progressively to, say, once a week.

A

B

C

BYPASS LINE

METER

STRAINER

VALVE

FLOW DIRECTION

9.2 Operating Precautions

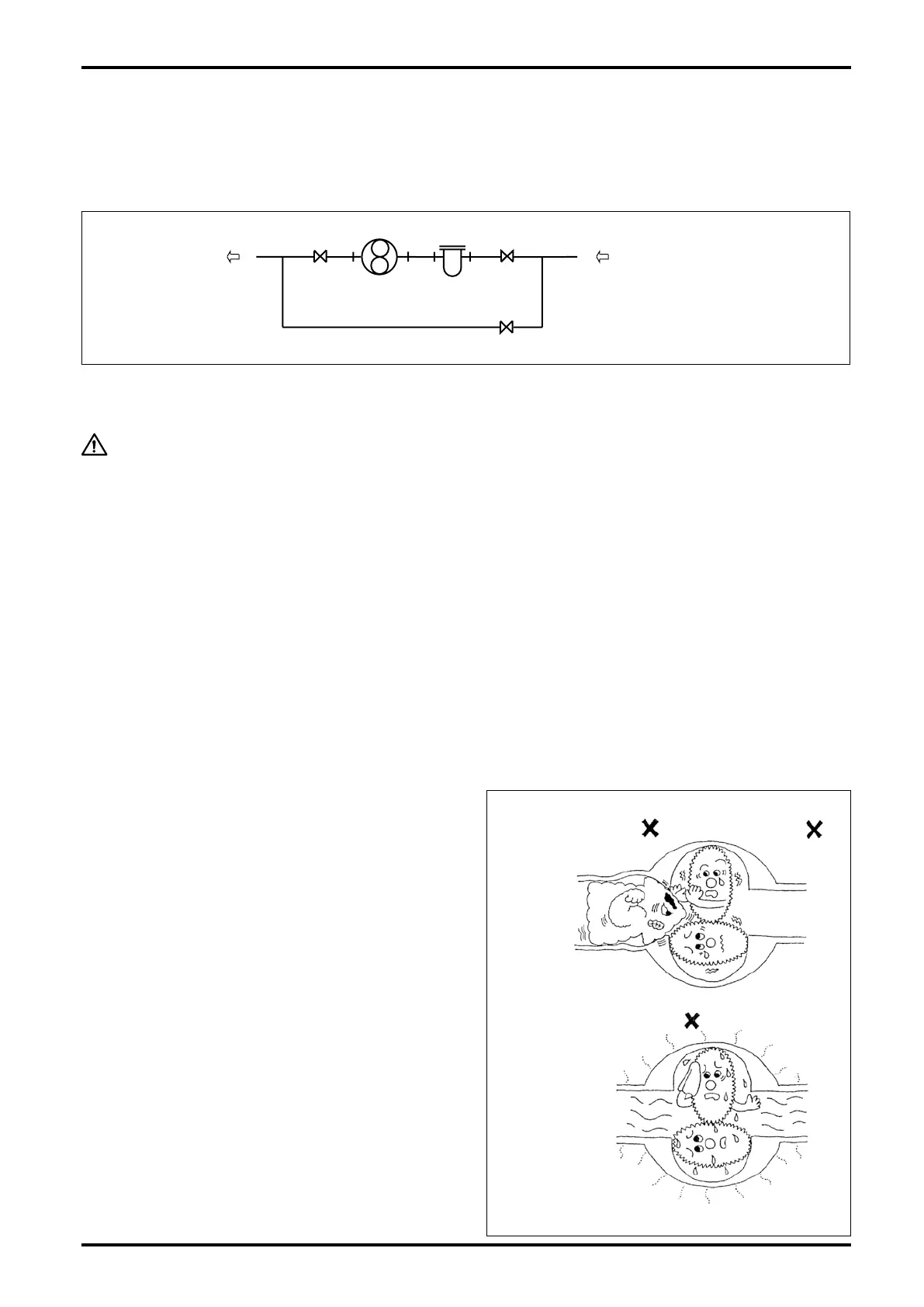

(1) When changing flowrates

In applications where the flowrate varies or where

shutoff valve opening and closure takes place in

batch operation, avoid rapid changes in flowrate

across the meter.

Operating the meter at flowrates in excess of

the maximum allowable flowrate will nullify the

guaranteed accuracy, reduce the meter life and may

result in faulty conditions, such as the seizure of

bearings or the rotor-to-measuring chamber contact.

(2) Where the temperature of metered fluid

changes

Avoid rapid temperature changes in the meter.

Temperature changes of the uid in the meter should

be held within 3°C per minute.

Extra care should be used particularly when making

a ow measurement in batch operation without the

provision of heat tracing of the piping where the uid

temperature differs from atmospheric temperature.

If rapid temperature changes are anticipated, heat

trace the piping assembly as well as the meter.

EXCESSIVE

FLOW

RAPID FLOW

VARIATION

RAPID TEMPERATURE

CHANGES

"See also page 15 for the jacketed type".

Loading...

Loading...