B-149-4N-E

16

10. DISASSEMBLY AND INSPECTION

Although it depends on individual operating conditions, periodic disassembly and inspection should be

performed at least once a year.

CAUTION: Because Smart Ultra OVAL is a precision industrial instrument,

disassembly and inspection should be performed indoors as a rule. If it is

desired to disassemble and inspect it as installed in the field, an important

precaution to remember is to reduce the internal pressure of the piping

assembly to a safe level, shut off valves upstream and downstream of

the meter fully, drain the piping assembly and then place a suitable fluid

receptacle directly below the Smart Ultra OVAL. Exercise care to keep

individual components disassembled free from grit and dust.

CAUTION: Be sure to deenergize before you disassemble.

◆

Meter Body Inspection

◆

Complaint and possible cause: Process fluid will not run. Jammed with scales, the oval rotors fail

to rotate, resulting in an interrupted fluid flow.

10.1 Size 50 Meter Body Disassembly and Inspection

METER BODY

HEX SOCKET

HEAD BOLTS

FRONT COVER

O-RING

HEX SOCKET

HEAD BOLTS

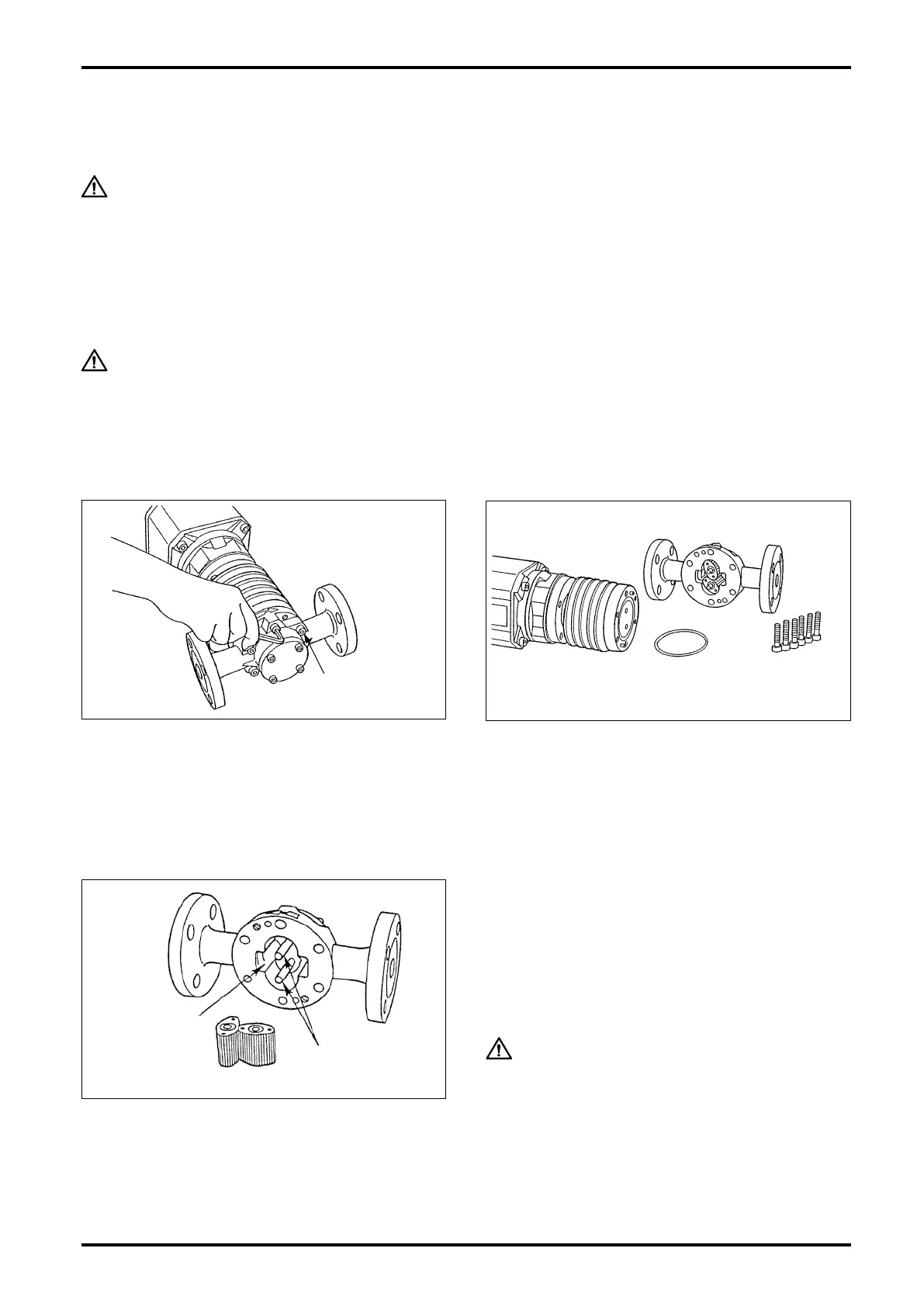

(2) With the front cover (register) removed, the

measuring chamber with oval rotors and other

components are now accessible.

(1) Take off all six front cover tting bolts (104) (M6),

using wrench.

With the bolts removed, the register integral with

the front cover is ready to be separated from the

meter body.

Be careful not to drop the register front cover

assembly.

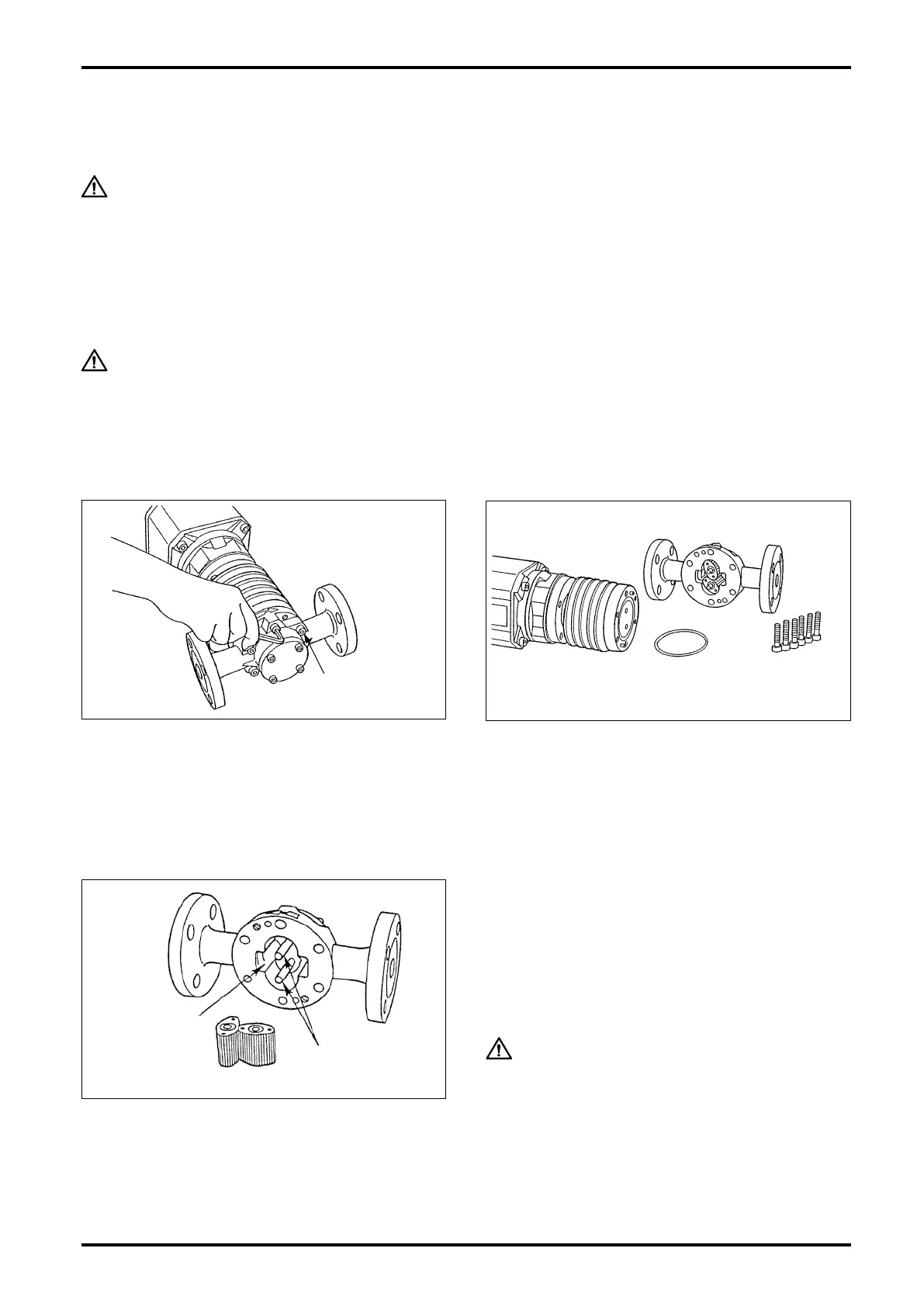

ROTOR SHAFTS

ROTORS

MEASURING

CHAMBER

(3) Remove oval rotors (201) from the measuring

chamber and inspect them for condition.

(a) Inspect the oval rotors to see if they are jammed

with foreign solids.

(b) Check the rotors, shafts and other members for

wear.

(c) Inspect the measuring chamber and the inner

wall of front cover for damage or any other sign

of unusual condition.

Upon completion of these inspections, clean the

oval rotors, rotor shafts, measuring chamber and

front cover with clean water or suitable solvent

thoroughly.

CAUTION

1. Score marks, scratches, high spots due

to impressions, or other flaws should

be reconditioned flat with oil stone or

other tool.

2. If the areas which have been in contact

with rear cover jack bolts are distorted

outwardly, recondition it flat with oil

stone.

Loading...

Loading...