steel enclosure)

Figure 3: XMT1000 enclosure clearances (ref. dwg. 712-2164)

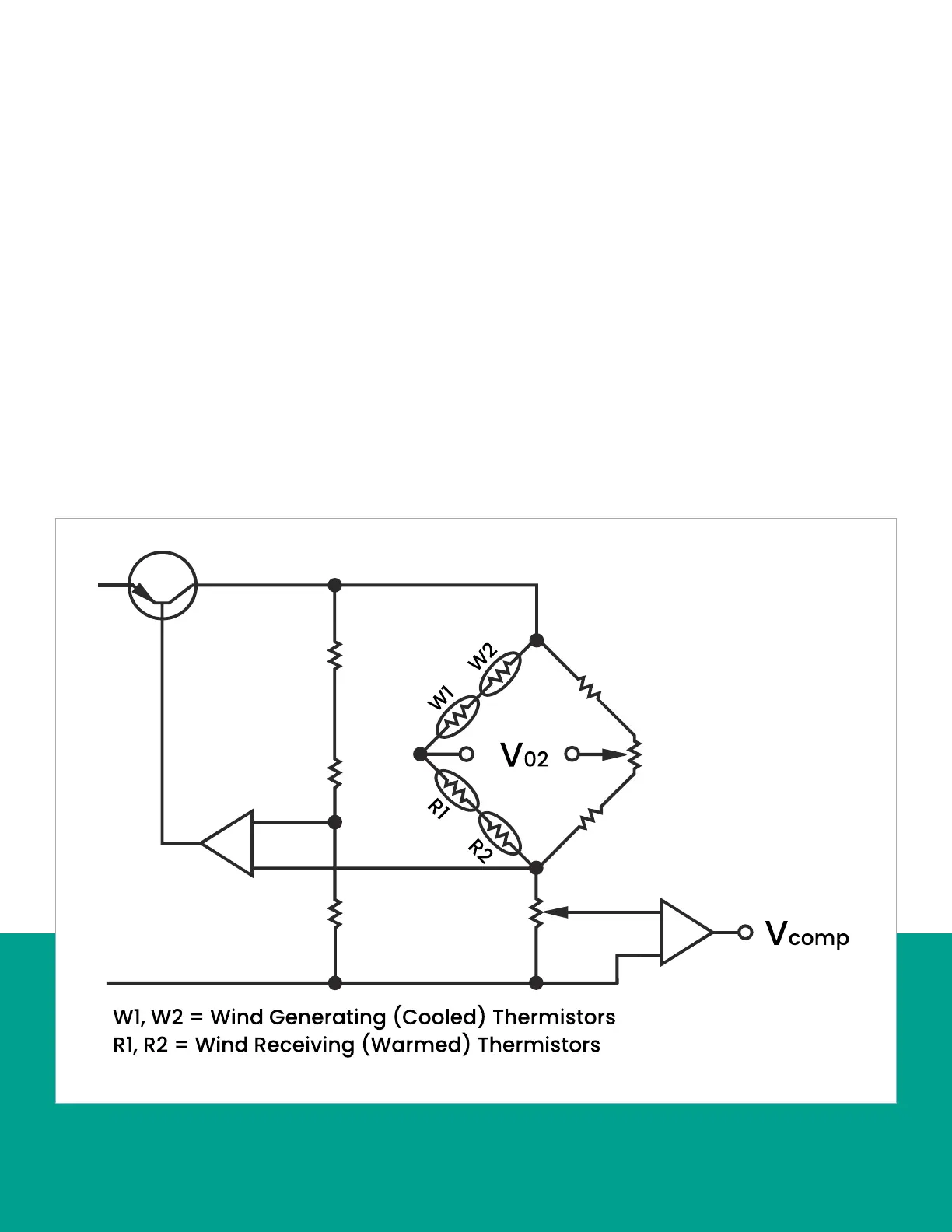

Figure 3 below shows how the two thermistor pairs are

connected in series in an electronic bridge circuit. The

bridge circuit becomes unbalanced as the electrical

resistance of the thermistors changes with temperature.

This circuit imbalance causes a voltage drop, which is

proportional to the oxygen concentration in the gas being

measured, to appear across the bridge circuit.

As the background gases that comprise the balance of an

oxygen-containing gas mixture change, the magnetic and

thermal properties of the gas mixture also change. This

affects the accuracy and response of any paramagnetic

oxygen analyzer. To compensate for such variations, the

XMO2 has a unique “bridge-within-a-bridge” design.

The oxygen measuring bridge circuit described on the

previous page is itself one arm of another compensation

bridge circuit that maintains the oxygen bridge at a

constant temperature as background gas composition

changes. The electrical power change necessary to keep

the oxygen bridge at constant temperature is a function of

the thermal properties of the background gas. Therefore,

this power fluctuation provides a signal that is related to

the thermal conductivity of the background gas. That signal

is then used to reduce the effects of the background gas

variation on the oxygen span point measurement.

In addition to maintaining a constant oxygen bridge

temperature, the XMO2 microprocessor compensates

for any zero point shift in the oxygen bridge circuit output

caused by background gas changes.

Finally, the bridge circuit voltage is further adjusted

for variations in background gas composition and/or

atmospheric pressure by internal, microprocessor-based

compensation algorithms. The compensated signal is then

amplified and converted to a 4-20 mA analog output that

is proportional to the concentration of oxygen in the gas

mixture.

3

Loading...

Loading...