GB/IE/NI/CY/MT

25

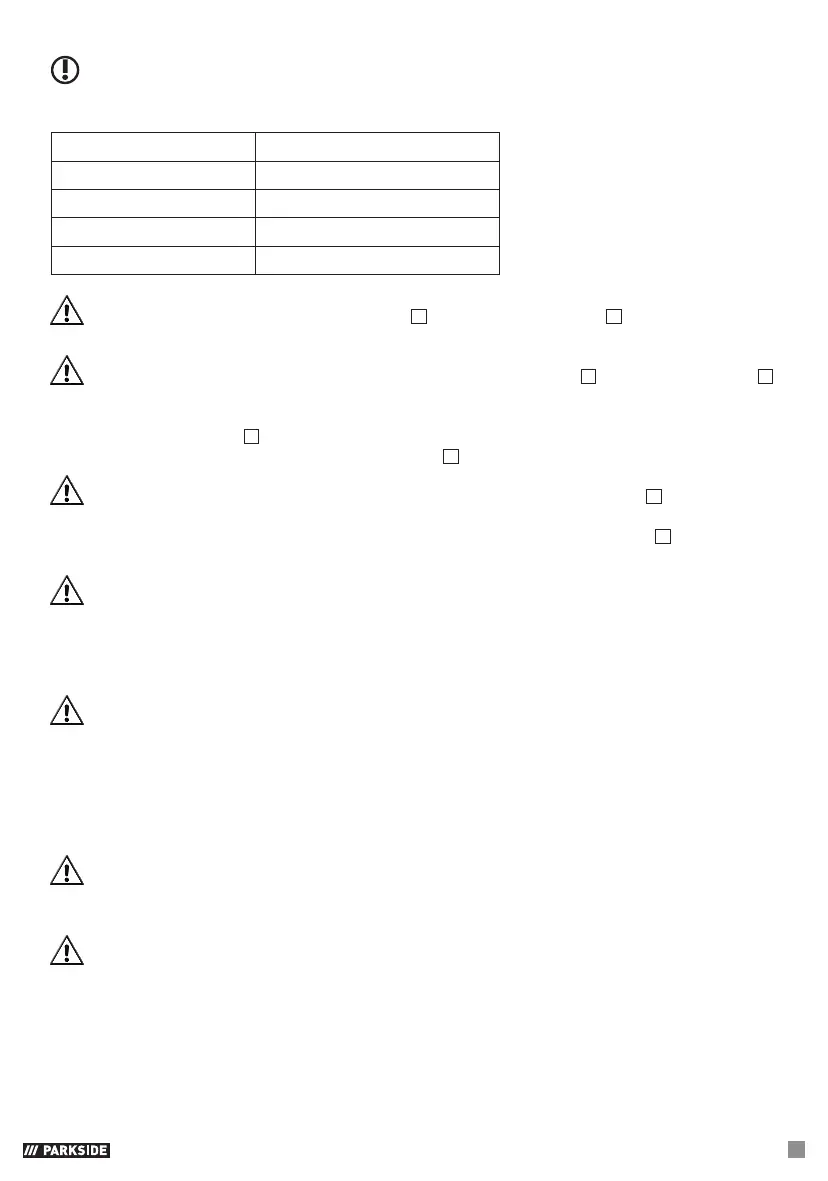

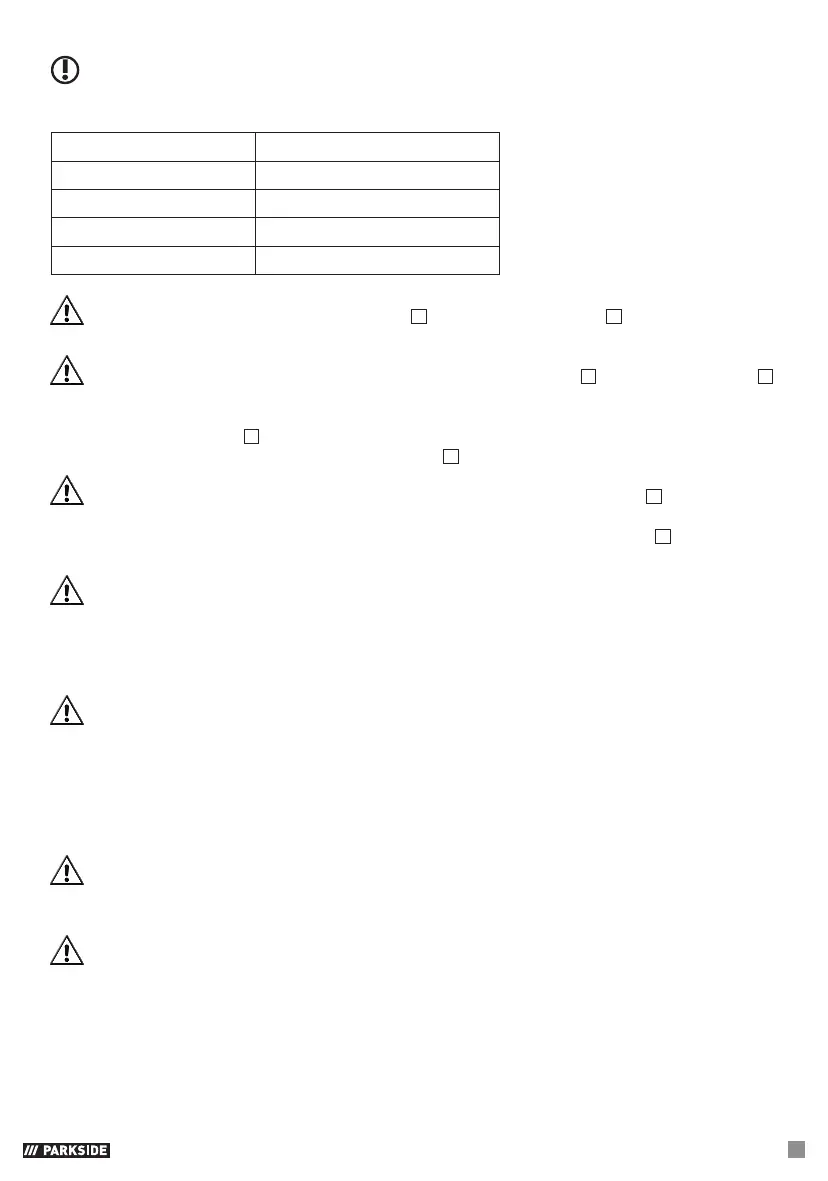

NOTE: Guideline values for the welding current to be used, depending on the electrode diameter

can be taken from the following table.

Ø Electrode Welding current

1.6 mm 40–60 A

2.0 mm 60–80 A

2.5 mm 80–100 A

3.2 mm 100–140 A

ATTENTION: Do not bring the earth terminal

4

and the electrode holder

34

/electrodes into direct

contact with one another.

ATTENTION:

When welding with rod electrodes, the electrode holder

34

and the earth terminal

4

must be connected in accordance with the information from the electrode manufacturer.

Hold the welding mask

22

in front of your face and start the welding procedure.

To stop the procedure, set the main switch ON/OFF

5

to “O” (“OFF”) position.

ATTENTION: When the thermal sensor is triggered, the O.H. display lights up.

37

In this case,

it will not be possible to continue welding. The device will continue to run so that the fan can cool the

device. As soon as the device is ready for operation again, the O.H. display goes out.

37

. The welding

function can now be used again.

ATTENTION: Do not dab on the workpiece with the electrode. It could be damaged and make

it more difficult to ignite the arc. As the soon as the arc is ignited, try to maintain a distance to the

workpiece which corresponds to the diameter of the electrode being used. The gap should remain as

constant as possible while you are welding. The inclination of the electrode in the direction of operation

should be 20–30 degrees.

ATTENTION: Always use pliers to remove used electrodes or hot workpieces. Make sure that the

electrode holder is always placed onto an insulated surface after welding. The slag can only be removed

from the seam once it has cooled down. To continue welding an interrupted seam:

First remove the slag at the connection point.

The arc is ignited in the weld groove, guided to the connection point, melted properly and finally the

weld seam is continued.

ATTENTION: Welding generates heat. Therefore the welding device must run idle for at least half

an hour after use. Alternatively, you can leave the device to cool for an hour. The device can only be

packed away and stored once the temperature of the device is normal again.

ATTENTION: A voltage which is 10% below the rated input voltage of the welder can have the

following consequences:

The power to the device will reduce.

The arc stops or becomes unstable.

Loading...

Loading...