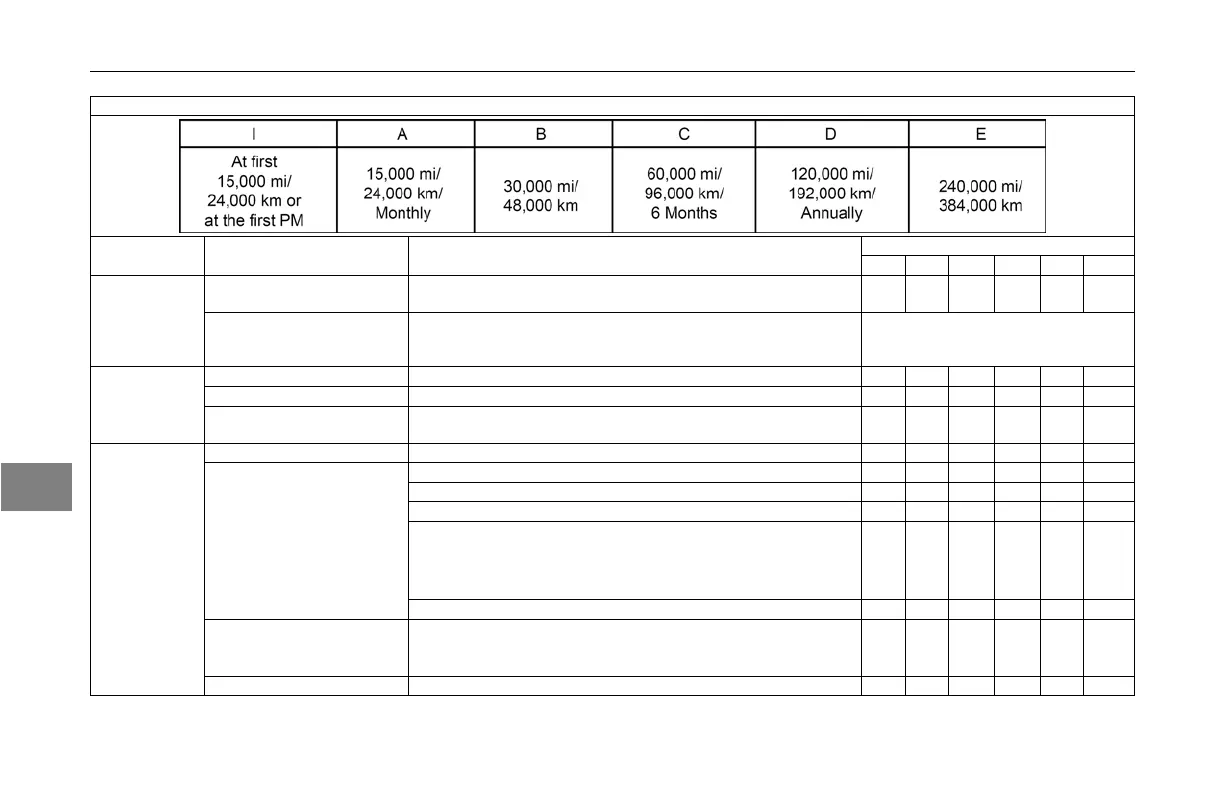

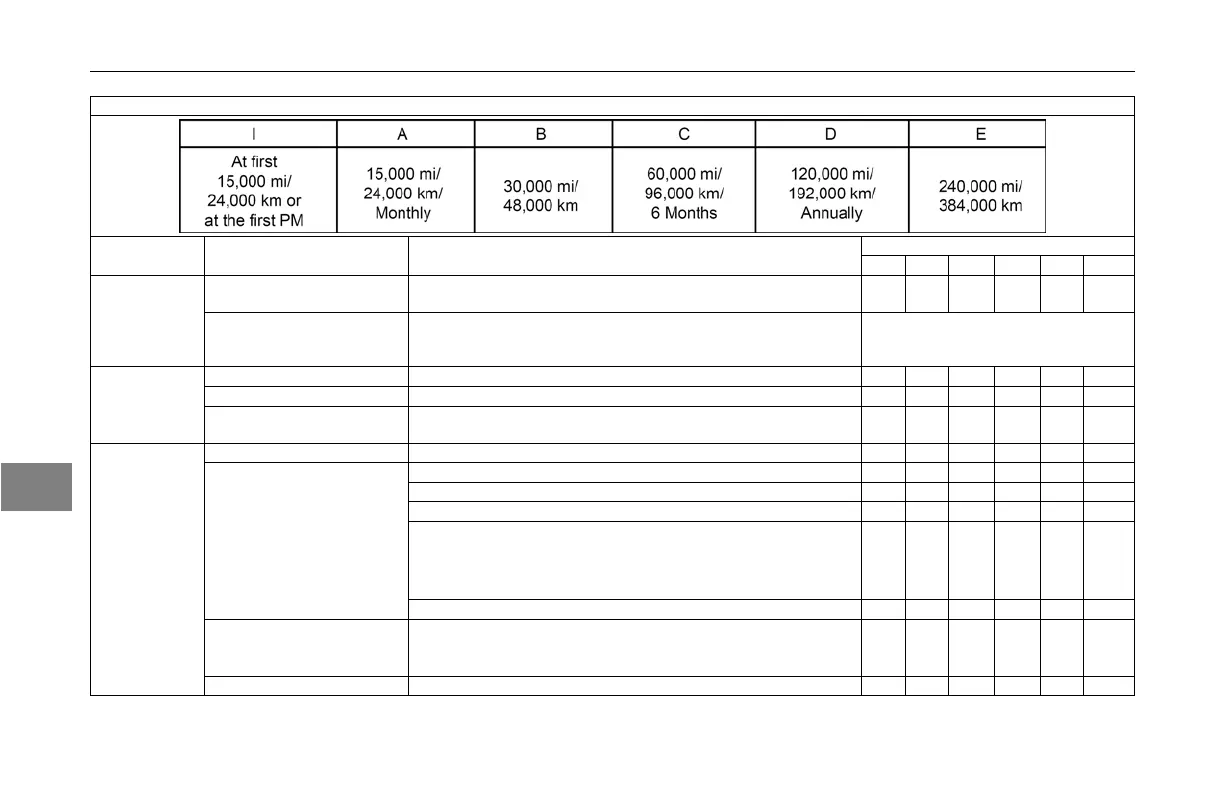

PREVENTIVE MAINTENANCE SCHEDULE

5

PREVENTIVE MAINTENANCE (PM) INTERVALS

SYSTEM COMPONENT MAINTENANCE TASK

Recommended PM

Interval

I A B

C

D E

Air Intake

Air intake piping, mounting,

and charge air cooler

Check the system for broken pipes, leaks, joint integrity,

cleanliness, and proper support (shown on page 5-99).

X

Air cleaner

Replace the engine intake air cleaner element (shown on page

5-98).

When required by air restriction

indicator or required by the engine

manufacturers operator manual.

Clutch Clutch hydraulic

uid Replace uid and bleed system.

X

Clutch release

bearing

Lubricate. X

Inspect and

adjust when necessary (no adjustment required

for SOLO type clutches)

X

Cooling

Hoses

Check the

radiator and heater hoses for leaks.

X X

Extended Life

Coolant

(ELC)

Check the freeze point (shown on page 5-72).

X

Check for

contamination using test strips (shown on page 5-71).

X

Replace blank

water lter if applicable.

X

Perform lab

analysis (shown on page 5-71).

If lab analysis shows coolant is unsuitable for continued use:

Flush, drain, and rell (shown on page 5-71).

Add ELC Extender (shown on page 5-71).

X

Flush, drain,

and rell with new coolant (shown on page 5-71).

X

Fan clutch

Check for air leaks. (shown on page 5-97).

Check the fan drive bearings (turn the sheave in both directions

to check for worn hub bearings).

X X

Solenoid valve Check the fan drive for proper engagement and disengagement.

X X

5-24 Y53-6047–2C (04/13)

Loading...

Loading...