Adjustment

14 - 22

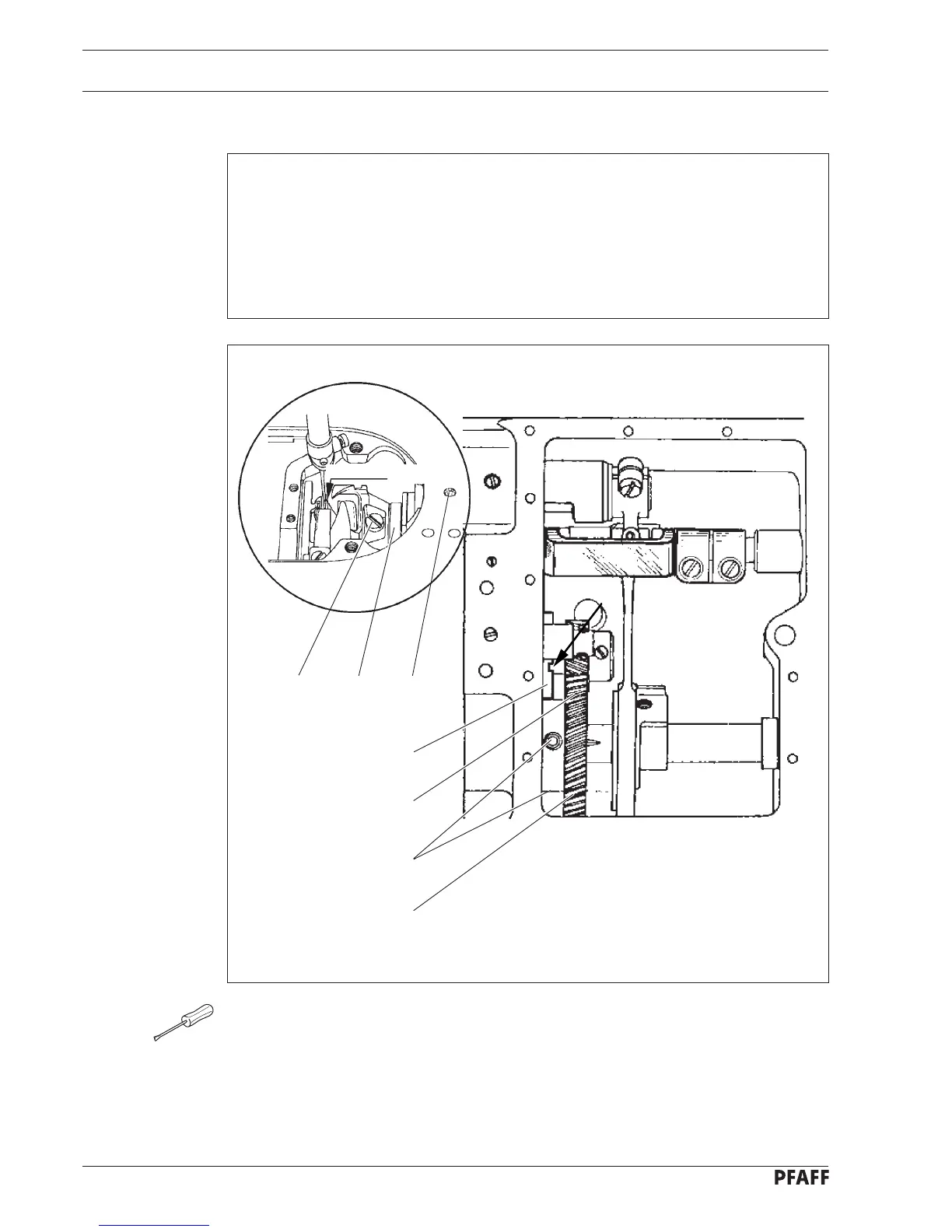

14.20 Eccentric hook shaft bearing

Requirement

1. The notch in bearing 3 (see arrow) must be visible from below.

There must be a slight but still noticeable play between gears 5 and 7.

2. With the hook lightly touching the spin disc 4 and the hook point opposite the center

line of the needle, there must be a clearance of less than 0.1 mm between the hook

point and the clearance cut of the needle.

3. Gear 5 must be flush with gear 7.

● Loosen screw 1 and both screws 2.

● Turn bearing 3 in accordance with requirement 1.

● Set the hook lightly against spin disc 4 and shift bearing 3, without turning it, in

accordance with requirement 2. Tighten screws 1 and 2.

● Position gear 5 (screws 6) in accordance with requirement 3.

5

6

7

3

142

max. 0.1 mm

Fig. 14 - 20

Loading...

Loading...