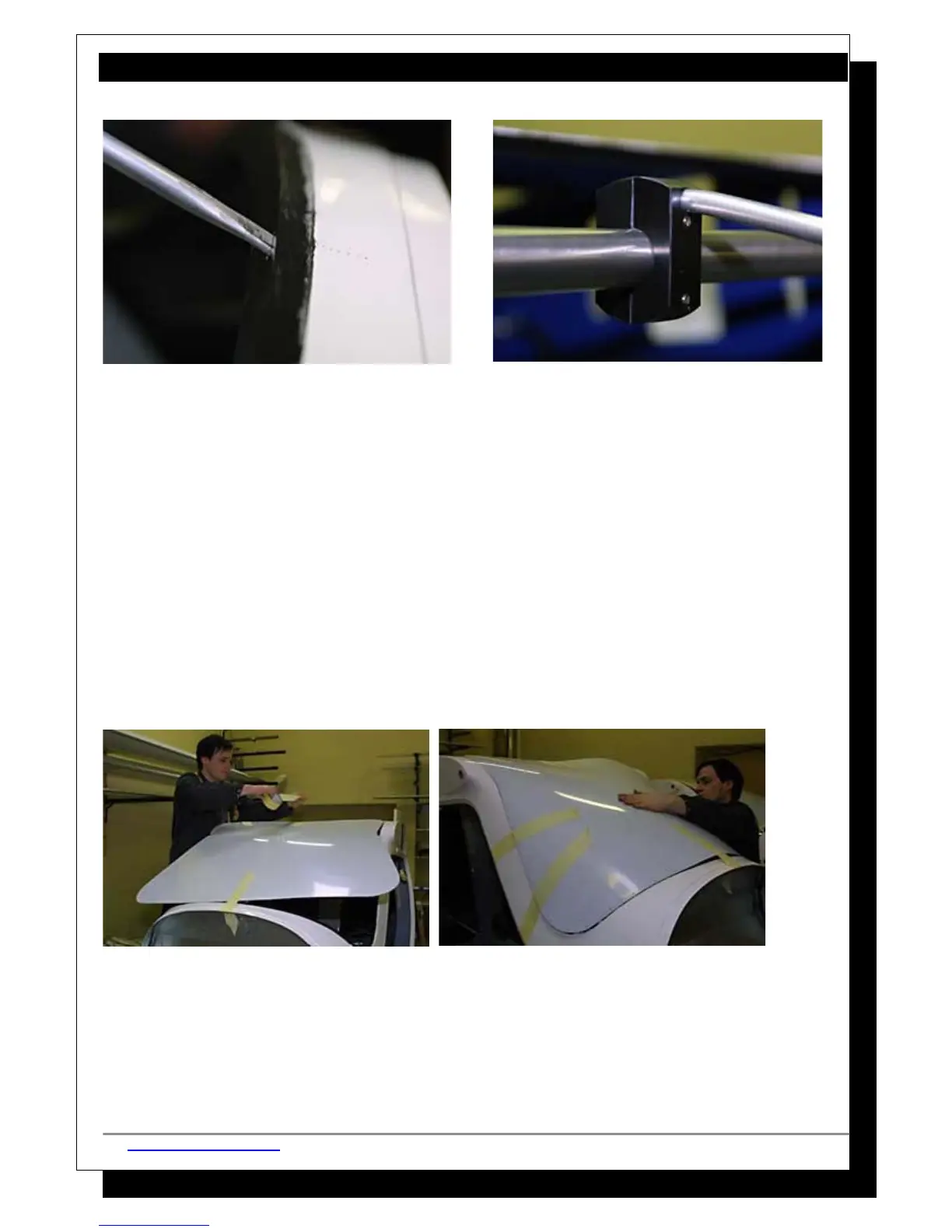

Secure the screen initially with tape to find the correct position. Make sure there is an

even gap around the windscreen of about 2mm. It will help if you have an extra person.

Drill the holes with a 3.2mm drill piece starting at the center hole near the firewall and

the center hole near the roof (use a Plexiglas drill if available). Make your way from the

roof downwards toward the firewall, drilling holes on both sides as you go.

Insert a small screw in each hole as you drill to keep the windscreen positioned correctly.

Do about 8 holes and then do a couple on the front. The idea is to meet in the bottom

front corner. Between each hole drilled and screw placed, push the lexan down otherwise

you can get ripples in the screen and the screen will not fit or be optically correct.

When all the holes are done remove the tape. Make sure to leave the lexan protective

covering on during these steps.

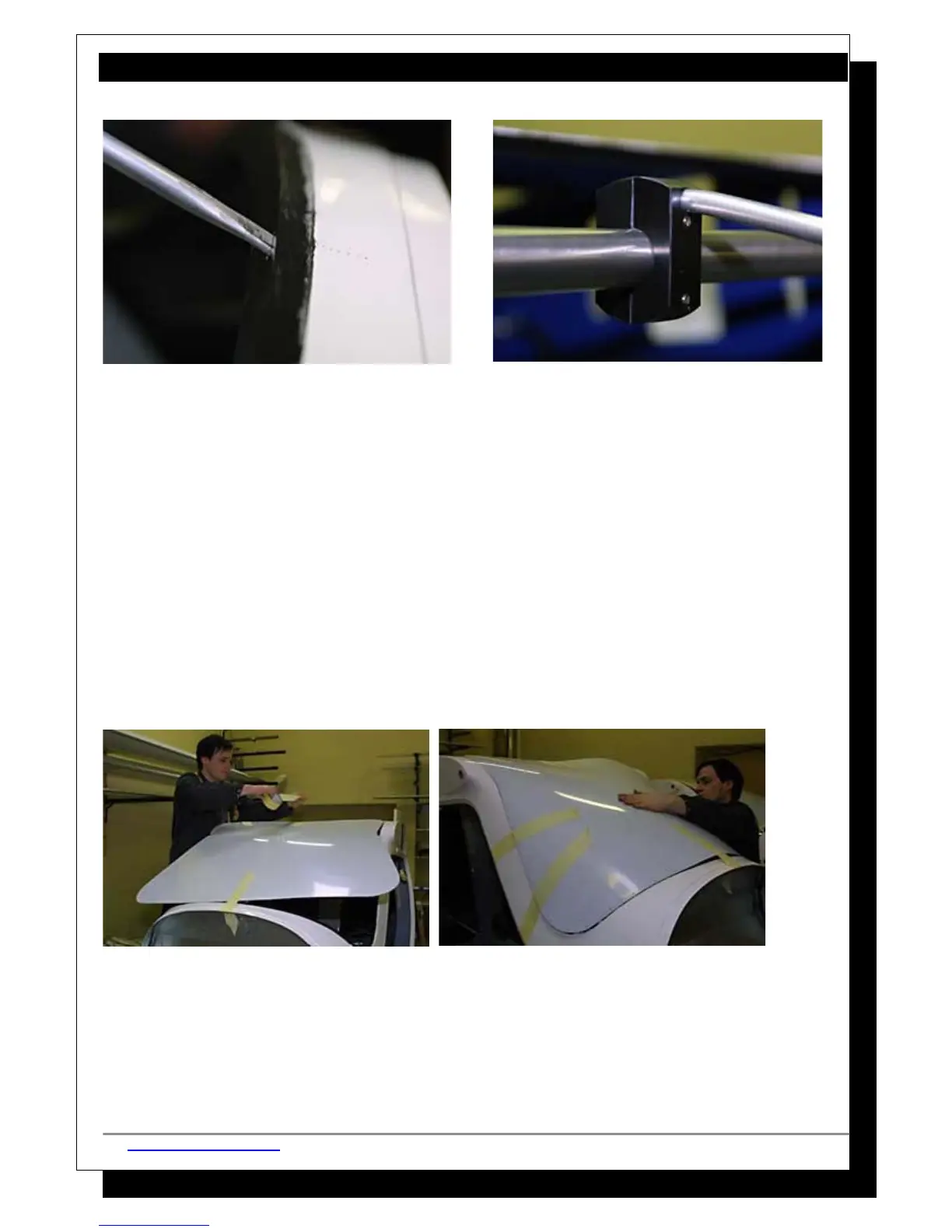

NOTE: it is important to use a drill stop to limit drilling depth to 10 mm. Around the bottom of

the windscreen it is not so crucial, but at the top there are two layers of fiberglass and you only

want to drill through one layer. The roof section has the double lip all the way around so the

special fitting must be used there also. It will look terrible and require repair if you go through

both layers.

http://www.pipistrel.si © Pipistrel Release March 2009 © Page 119 of 267

Loading...

Loading...