page 54

Industrial Power Corruptor Manual Rev 1.00

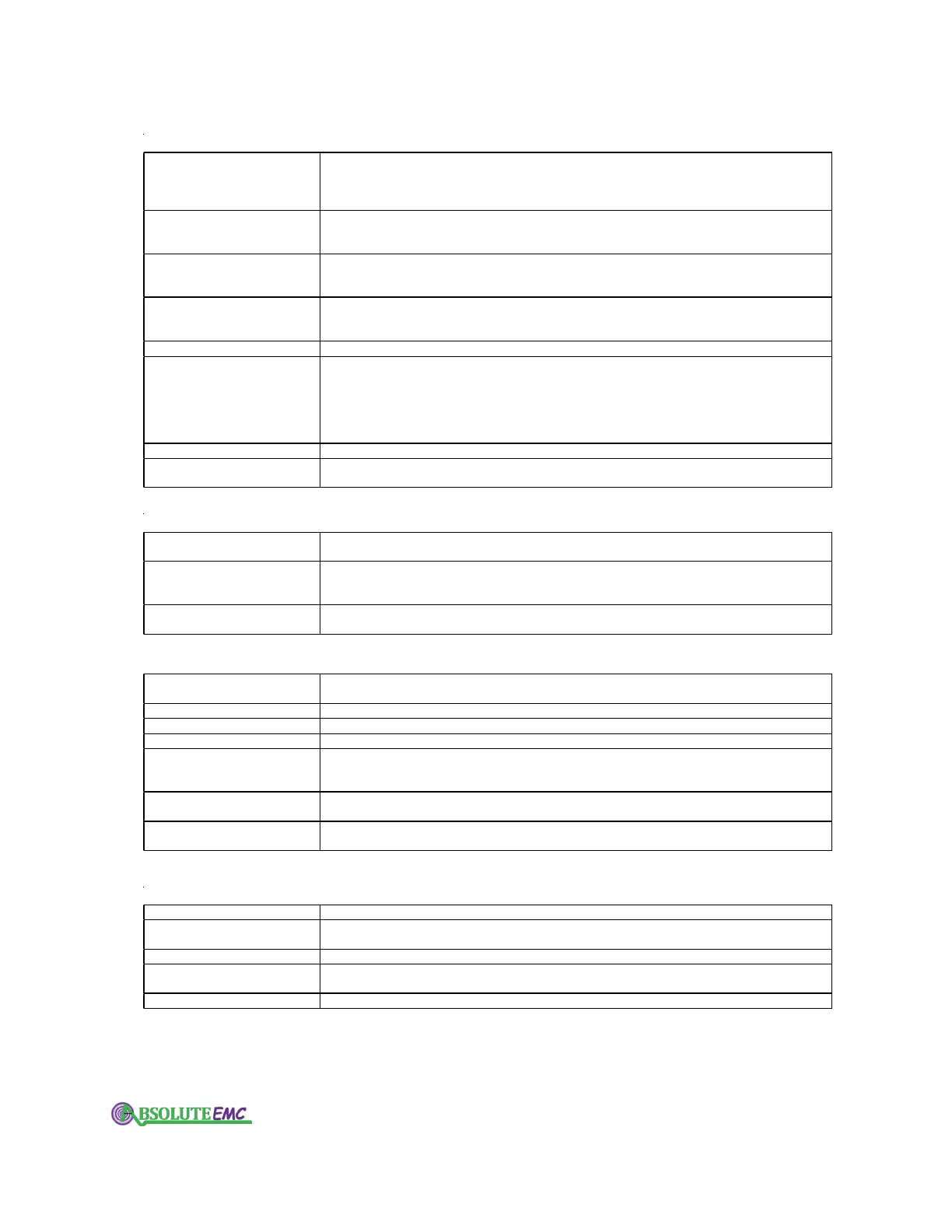

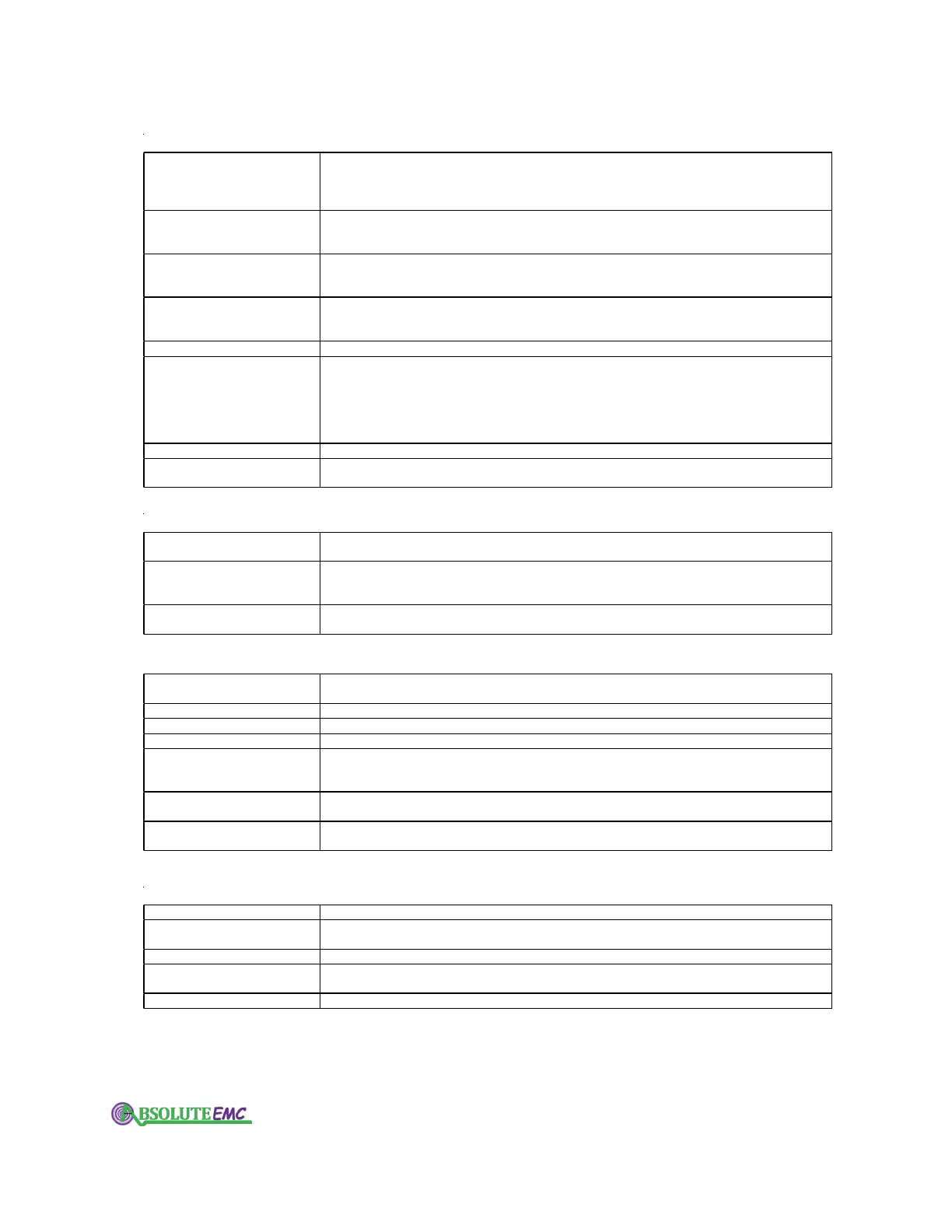

Appendix B - Specifications - general

General specifications

Functional

Voltage Sag/Dip and Swell testing per SEMI F47, IEC 6100-4-11, CBEMA, ITIC, MIL

STD, FAA, SAMSUNG, and other international standards. With Power Flow Analysis

option, also performs to SEMI E6, current inrush testing, harmonic current testing, and

more.

Agency approvals

Designed to meet U.S. and Canadian safety standards, CE certification requirements,

FCC requirements. Fully meets requirements of IEC-1010, and IEC-61000-4-11. Fully

meets requirements and recommendations of SEMI F47.

Equipment ratings

Rated as Class I equipment. Rated for Installation Category II (local level, appliances,

portable equipment). Rated for Pollution Degree 2 (Normally, only non-conductive

pollution occurs.)

Operating environment

Indoor use. Altitude up to 2000 m. Temperature between 5°C and 40°C. Max relative

humidity 80% for temperatures up to 31°C decreasing linearly to 50% relative humidity at

40°C.

Instrument Power

100 to 240 Vac (±10%), 50/60 Hz, 4 Amps max.

Software

Industrial Power Corruptor program for setup/operation of IPC, viewing real-time and

downloaded data, and collecting information for test report generation. W ith Power Flow

Analysis option, software includes vector scope, real-time oscilloscope, and real-time

spectrum analyzer. ChannelScope II software for viewing, zooming, scrolling, and

synchronizing power waveforms. FlowScope software for graphing and examining power

flow over time. Requires PC with Windows 98 or XP.

Communications Front panel RJ-45 jack for serial connection to PC.

Physical

19 inch rack-mount unit in rugged polyethylene case measuring 21in. W x 11in. H x 30

in.L (50cm x 28cm x 76cm). 130lb (59Kg)

Permissible Test Conditions

Voltage Range

100 – 480 Vrms, 50 or 60 Hz, 1-phase or 3-phase. Voltage is limited to 240Vrms on

some model numbers.

Voltage Configuration

Single phase or 3-phase (Y or delta) connection to unit. Voltage dropout testing can occur

on all phases simultaneously. Voltage sag and swell testing on a single pair of phases, or

phase to neutral. Phase selection for events is done with front panel dial.

Load Current

Up to 200 Amps per phase continuous, depending on model number. 600 Amps peak.

Front panel dial for user selection of current trip point.

Voltage Sag / Swell Testing

Magnitude

0% to 125% of nominal voltage in 2.5% steps. User can select 0% sag to be either high

impedance or low impedance.

Duration User selected duration from 0.1 cycles to 34 seconds in 0.1 cycle steps.

Magnitude/Duration Margin A front panel switch allows quick 5% or 10% increase in event magnitude and duration.

Phase Angle 0 to 359 degrees in 1-degree steps.

Event Trigger Input/Output

Manual front panel “Arm” and “Fire” switches locally trigger event. Rear panel BNC

connectors provide bi-directional 24V logic level (falling edge) trigger output and input

capability.

Semiautomatic Sequencing

As well as manual event configuration, the user can semi-automatically step through a

industry standard recipe on a single or 3-phase system.

Switching Method

High speed, gapless switching, IGBT package with patent-pending override design for

long duration events.

Three Phase Voltage Dropout and Current Inrush Testing

Magnitude Full voltage and current rating of Industrial Power Corruptor

Max instantaneous current

recording

±1 000A instantaneous

Interruption Duration 0.3 to 34 seconds.

Phase angle

0 degrees to 355 degrees in 5 degree steps. Referenced to user selected voltage

channel.

Switching Method Mechanical relays, with calibrated switching times to 0,4 milliseconds

absolute-emc.com

Phone:703-774-7505

info@absolute-emc.com

Loading...

Loading...