Service and Maintenance: Strainer Maintenance Procedure 67

SERVICE AND MAINTENANCE

STRAINER MAINTENANCE PROCEDURE

The strainer must be cleaned and inspected periodically or when system performance degrades. Refer to the

following procedure to disassemble and maintain the strainer to ensure that the AccuFlow system is operating

properly.

1. Refer to the Discharging the AccuFlow™ System and ensure that all NH

3

has evaporated and vapors have been

exhausted before proceeding.

2. Remove the strainer cap and remove the ceramic magnets, teflon washer and strainer screen (not shown).

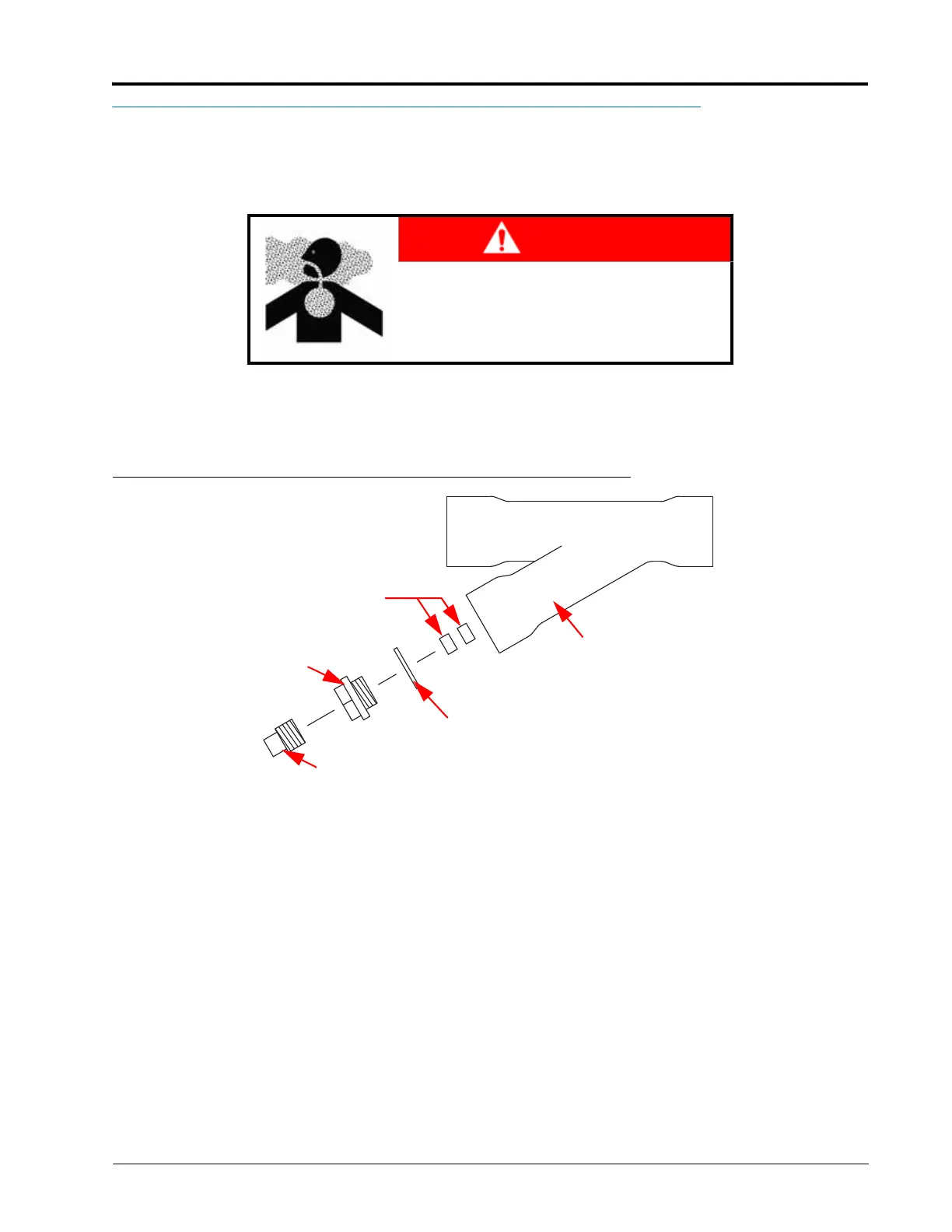

FIGURE 4. Y-Strainer Components

3. Clean the ceramic magnets to remove excess grit or debris.

4. Clean and inspect the teflon gasket and strainer screen and replace as necessary.

5. Replace strainer screen and ceramic magnets into strainer body.

6. Place the teflon gasket onto the strainer cap.

7. Thread the strainer cap into the strainer body.

IMPORTANT: Avoid strainer damage. Use care to align strainer in housing and turn strainer cap all the way by hand. Do

not force with pipe wrench or strainer screen can be crushed.

8. Tighten the cap using a pipe wrench to secure the strainer assembly before operating the AccuFlow system.

DANGER

Anhydrous ammonia can cause severe burning,

blindness, or death. Refer to Discharging the

AccuFlow™ System section on page 5 or page 61

and follow the procedure for bleeding the

AccuFlow system before beginning maintenance.

Strainer

Body

Ceramic

Magnets

Teflon

Gasket

Strainer

Cap

Strainer Plug or

Bleeder/

Hydrostat

Loading...

Loading...