MODULAR SAFETY INTEGRATED CONTROLLER MOSAIC

36 8540780 • 10/07/2020 • Rev.38

PROXIMITY INPUT FOR SPEED CONTROLLER MV

An inadequate mechanical installation of proximity sensors can cause dangerous operation. Pay

particular attention to the size of the phonic wheel and to the mechanical fixing of the sensors.

In any condition of expected speed, the MVxxx module must be able to detect the speed.

During the installation (and then periodically) perform a complete system test. By using the

MSD software or by checking that the LEDs relating to the sensors are lit, make sure that the

module does not detect any anomalies in any case.

The sizing of the exciter and the positioning of the sensors must be done following the technical

data of the latter and the manufacturer’s guidelines.

Pay particular attention to Common Cause Failures (CCF) that may involve both sensors (short

circuit of cables, objects falling from above, idle rotation of the phonic wheel, etc.)

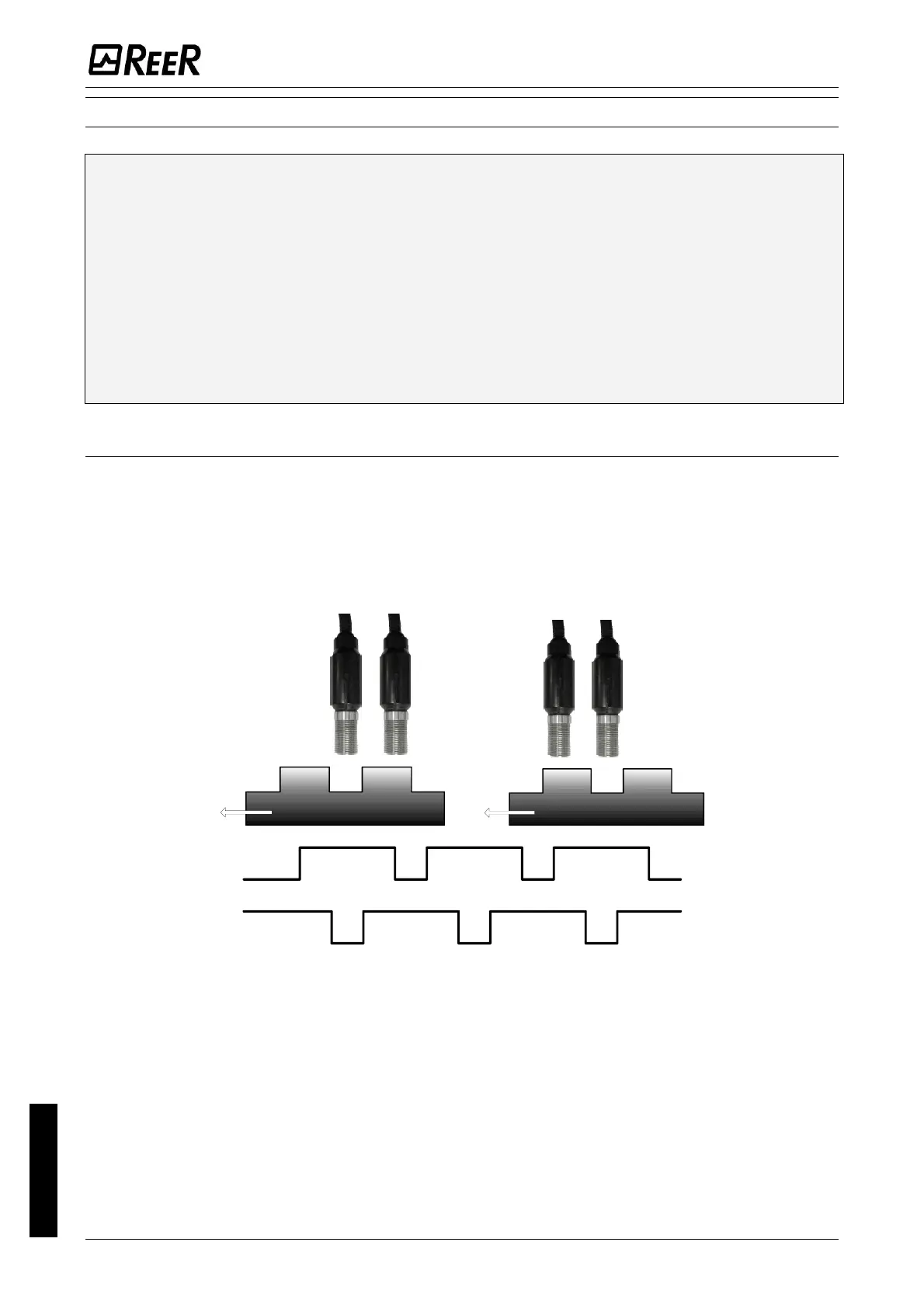

Configuration With Interleaved Proximity

When an axis of the MV modules is configured for a measurement with two proximity

switches, these can be configured in interleaved mode. Under the conditions listed below

the system reaches a Performance Level = PLe:

Proximity switches must be fitted such that the recorded signals overlap.

Proximity switches must be fitted such that at least one is always activated.

Figure 7

In addition:

The proximity switches must be PNP type.

The proximity switches must be NO type (Output ON when detecting metal).

With the above conditions fulfilled, the DC value is equal to 90%.

The two proximity switches must be of the same model, with MTTF > 70 years.

Loading...

Loading...