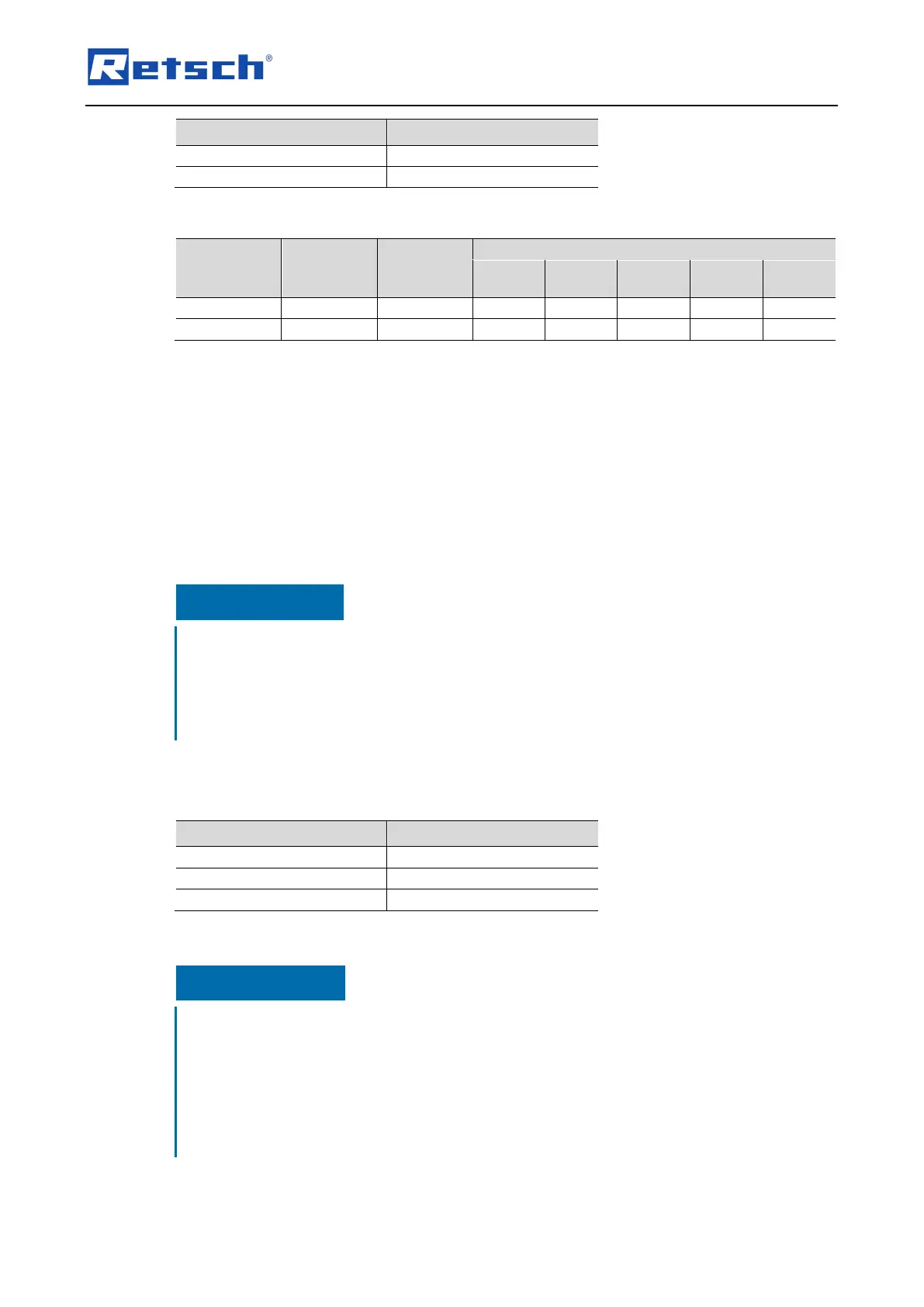

6.9.2 Recommended Grinding Jar Filling

Recommended number of grinding balls

In addition to the instrument settings, the filling level of the grinding jar is also of crucial

importance for a successful grinding process in the High Energy Ball Mill of Retsch GmbH.

When grinding bulk materials, the grinding jar filling should consist of approximately one

third of sample and one third of ball quantity. The remaining third is the free grinding jar

volume, which is required for the movement of the balls.

If an increase or decrease in sample volume is to be expected during the grinding process, the

amount of sample can be adjusted within the range listed in the table. Thus, e.g. for voluminous

materials such as wool, leaves, grasses and similar, a material filling level of 70 – 80 % is

necessary. For wet grinding with grinding balls < 3 mm, the ball charge should be 60 % of the

grinding jar volume.

Cryogenic grinding

Grinding with liquid nitrogen (LN

2

) or dry ice

− When grinding with liquid nitrogen or dry ice, breakage of the grinding set

and damage to the device can occur!

• Grinding with liquid nitrogen or dry ice is not permitted!

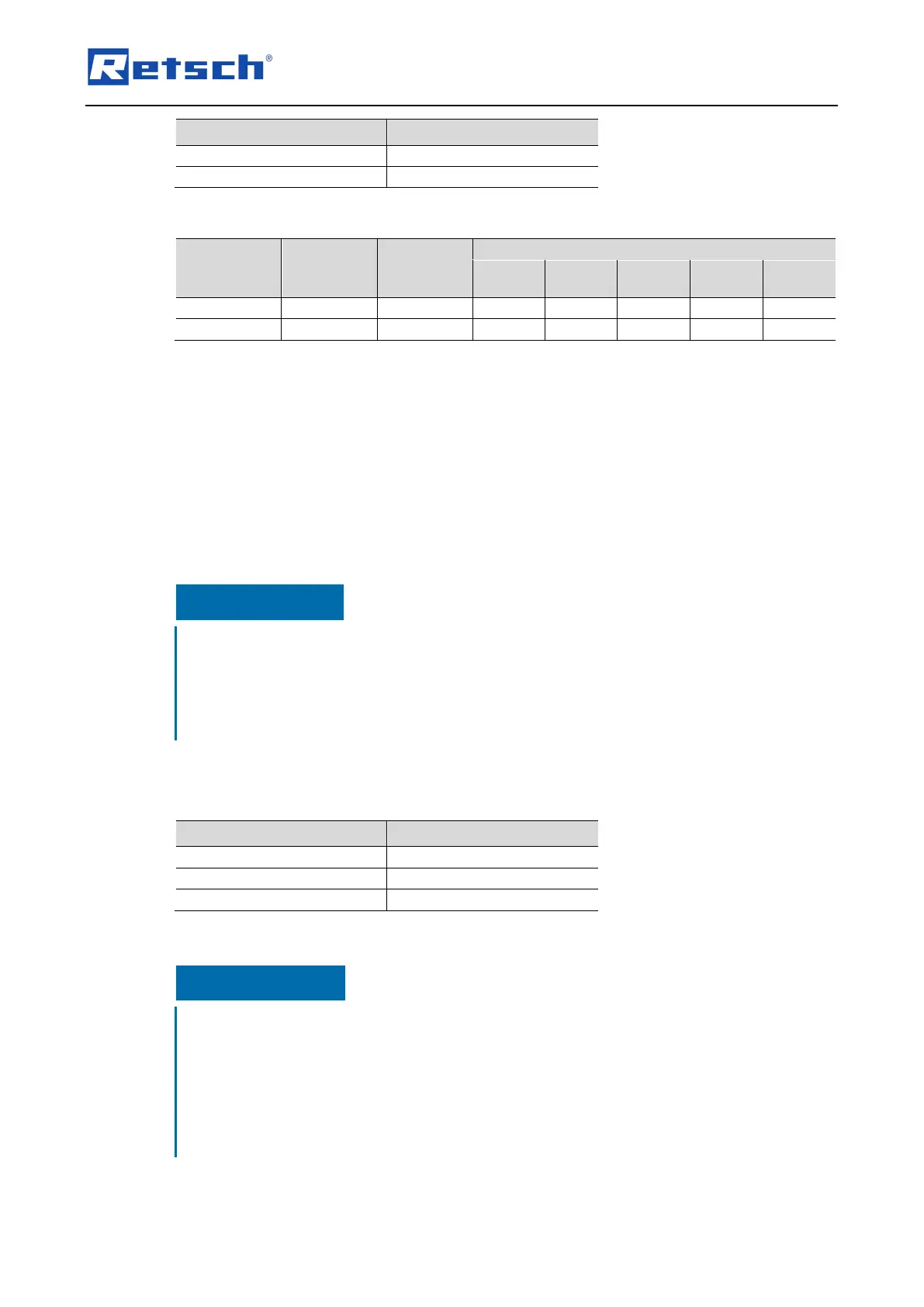

6.9.3 Recommended Speeds

The following speed restrictions apply to grinding balls larger than or equal to 10 mm:

6.10 Inserting the Grinding Jar

Strong vibrations and loud noise

Uneven loading

− The device can generate particularly strong vibrations and loud noise if

loaded unevenly.

• Always insert two grinding jars of equal size, even if you only want

to grind one sample. In this case leave the second grinding jar

empty (no grinding balls, no sample material)!

Loading...

Loading...