10 Accessories

Information on available accessories as well as the respective manuals are accessible directly

on the Retsch GmbH homepage (http://www.retsch.com) under the heading "Downloads" of the

device.

Information on wear parts and small accessories can be found in the Retsch GmbH general

catalogue also available on the homepage.

In case of any questions concerning spare parts please contact the Retsch GmbH

representative in your country, or Retsch GmbH directly.

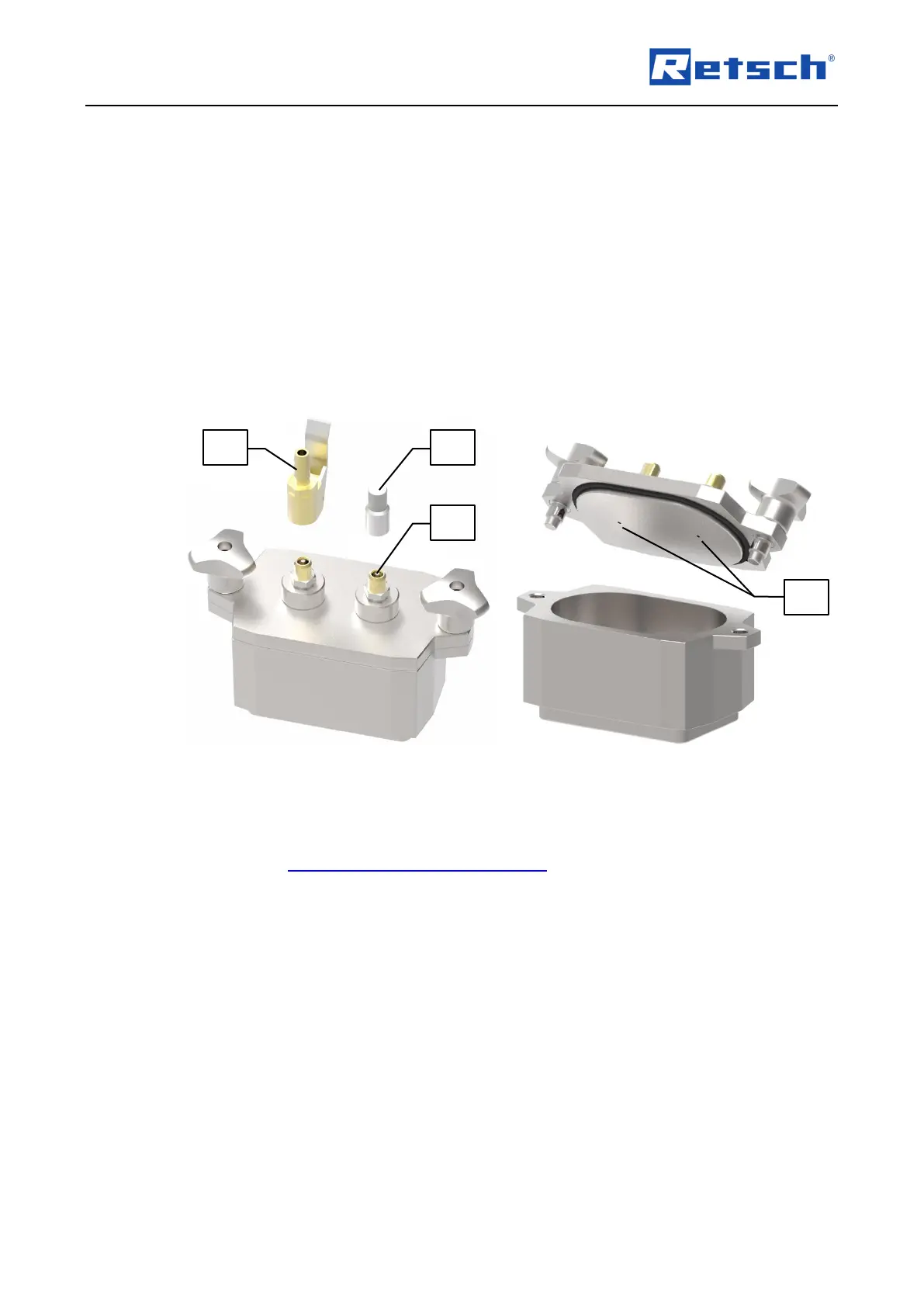

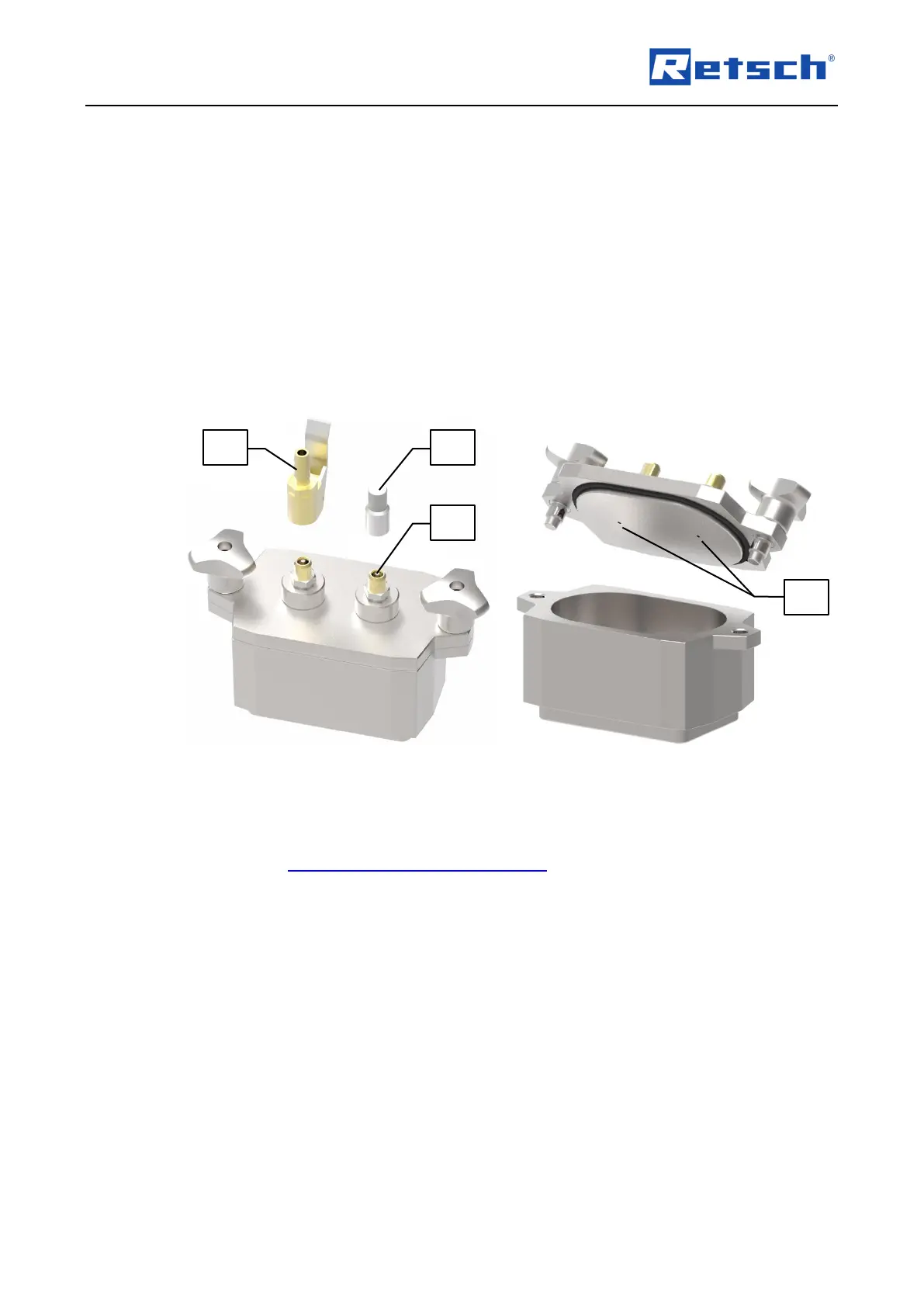

10.1 Aeration Lid

By using the optional aeration lid, grinding processes can be carried out in an inert atmosphere.

Put the grinding material together with the grinding balls into the grinding jar.

Close the grinding jar with the aeration lid. Use the opening aid (OE) for this purpose

(→ Chapter "Opening and Closing the Grinding Jar").

Clip the supplied valve nipple (BD1) on one of the two valves (BD3). The valve is

permanently opened by the valve nipple.

Screw the supplied valve cap (BD2) onto the other of the two valves (BD3). The valve can

be opened by pressing the valve cap.

Connect the desired inert gas to the valve nipple (BD1) using a hose (not supplied).

Let the inert gas flow through the valve nipple (BD1) into the grinding jar, while

simultaneously pressing on the valve cap (BD2) to allow the air to escape from the grinding

jar and be replaced by the inert gas.

Once all air in the grinding jar has been replaced with the desired inert gas, release the valve

cap (BD2) (usually after a few seconds). The valve closes.

Stop the supply of the inert gas and remove the valve nipple (BD1).

Unscrew the valve cap (BD2).

Alternatively, a negative pressure can be generated in the grinding jar instead of an inert

atmosphere. For this purpose, instead of a gas cylinder, a compressor can be connected to the

valve nipple (BD1). The valve cap (BD2) remains permanently closed during this procedure.

Loading...

Loading...